Assembly type high-pile bearing platform for offshore wind power

A high-pile cap, offshore wind power technology, applied in the installation/support of wind turbine configuration, wind power generation, construction, etc. The effect of controlling construction quality, stable production workshop environment and high degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

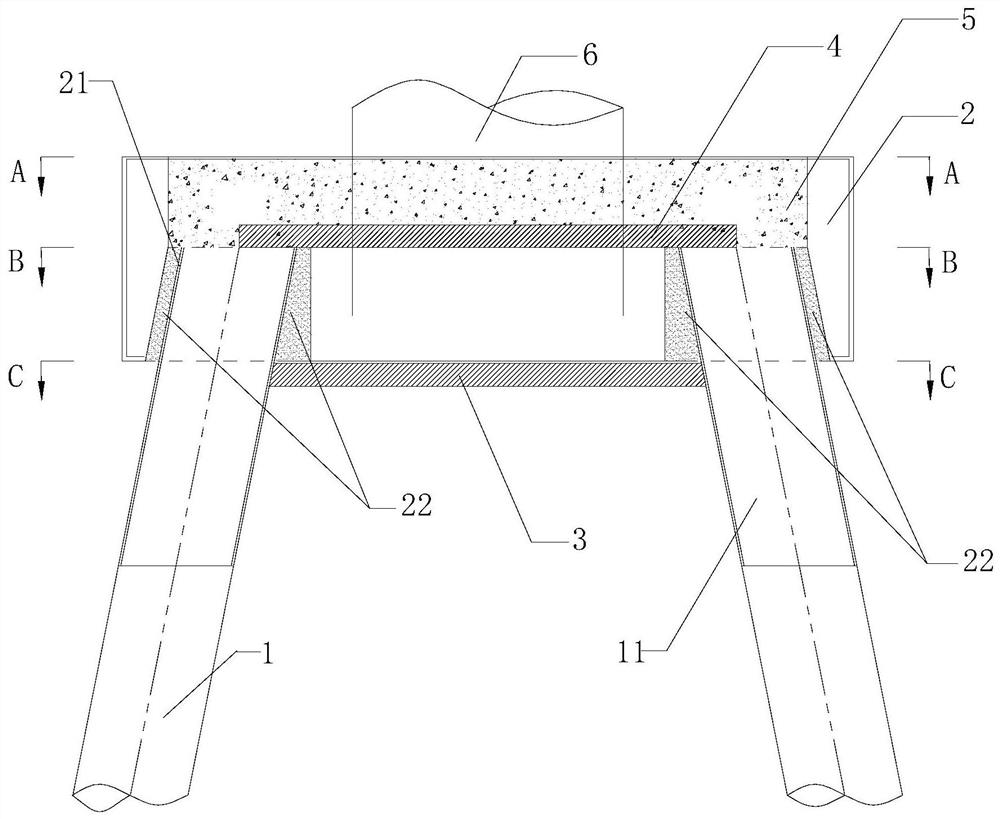

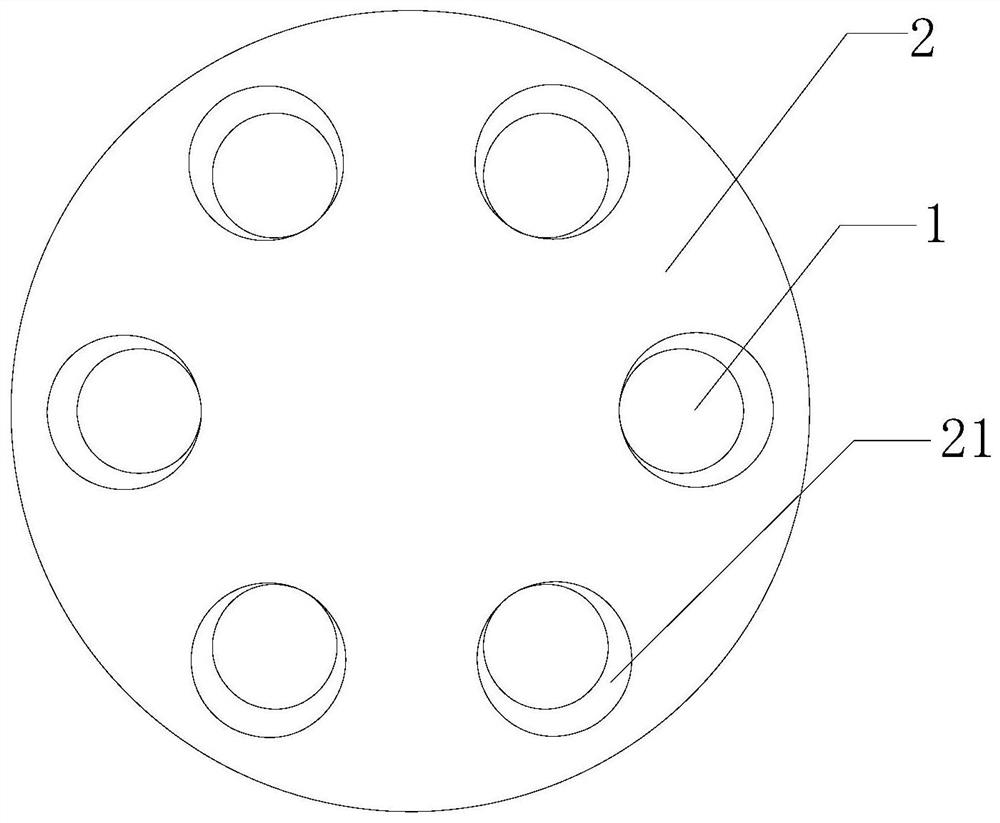

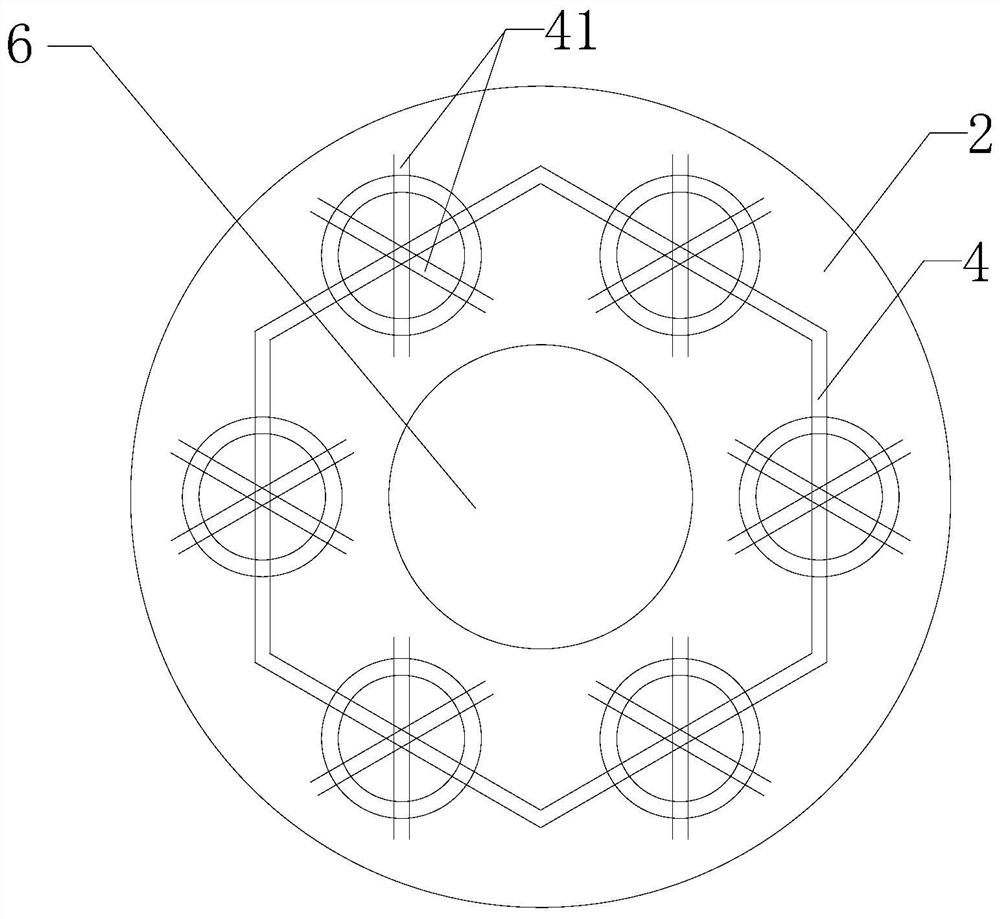

[0025] see Figure 1~4 , the figure shows the assembled high pile cap for offshore wind power of the present invention; including:

[0026] A number of steel pipe piles 1 embedded in the bedrock, in this embodiment, a plugging device (not shown in the figure) is provided inside the steel pipe pile 1, and concrete material is poured into the steel pipe pile 1 to form a pile core 11. The device is located at the height inside the steel pipe pile 1 to control the length of the pile core 11. The number of steel pipe piles 1 is six, and the axes of the six steel pipe piles 1 at the same height are evenly distributed on the same circle. The steel pipe pile 1 is embedded in the bedrock in an oblique shape and the top is flush with the horizontal plane;

[0027] A lower cap 2 erected on the upper ends of several steel pipe piles 1, the bottom of the lower cap 2 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com