Hollow glass extension mounting structure

An installation structure and hollow technology, which is applied in the installation of window glass, building components, building structure, etc., can solve the problems of easy damage of glass, no protective structure on the side of glass, inconvenient use of small frame doors and windows or hanging doors and windows, etc. , to achieve the effect of reducing the probability of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

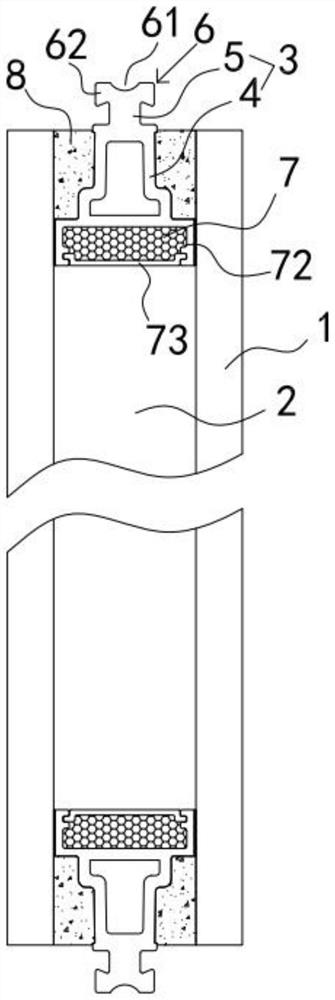

Embodiment 1

[0020] Such as Figure 4 As shown, it is a common hollow glass structure. A hollow aluminum strip 71 is embedded in the middle of the two glass layers 1 to form a hollow sealed cavity 2 filled with dry gas, and a sealant 8 is applied outside the hollow aluminum strip 71 to complete the seal. The hollow part of the hollow aluminum strip 71 forms a desiccant sealed cavity 7, and the desiccant sealed cavity 7 is filled with a desiccant.

[0021] Under this structure, the hollow aluminum strip 71 is completely embedded, and only the sealant 8 that is flush with the glass edge can be seen on the outside. When the insulating glass needs to be installed later, it is necessary to set a profile groove that can place the entire insulating glass. Both sides of the glass are wrapped with profiles, which will inevitably make the doors and windows installed with insulating glass more bloated, and cannot be installed on small frame doors and windows, or hanging doors and windows; All need t...

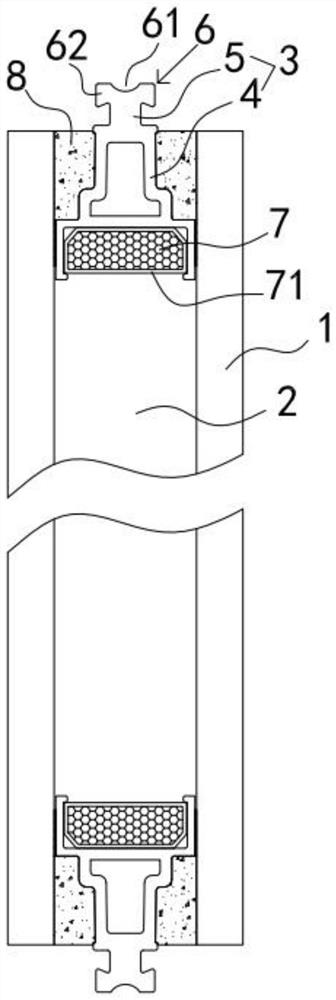

Embodiment 2

[0029] Such as figure 2 As shown, the difference between this embodiment 2 and embodiment 1 is that the desiccant sealing chamber 7 of the embedded part 4 does not use the aluminum sheet 73, but directly uses the hollow aluminum strip 71, through the hollow airtightness of the hollow aluminum strip 71 itself , form the desiccant sealed cavity 7 and fill it with desiccant, and then insert the hollow aluminum strip 71 into the inside of the embedded part 4 .

[0030] The scheme of this embodiment can directly follow the traditional structure of the existing hollow aluminum strip 71, and add the hollow aluminum strip 71 to the embedded part 4 embedded in the profile 3, which is simple and effective.

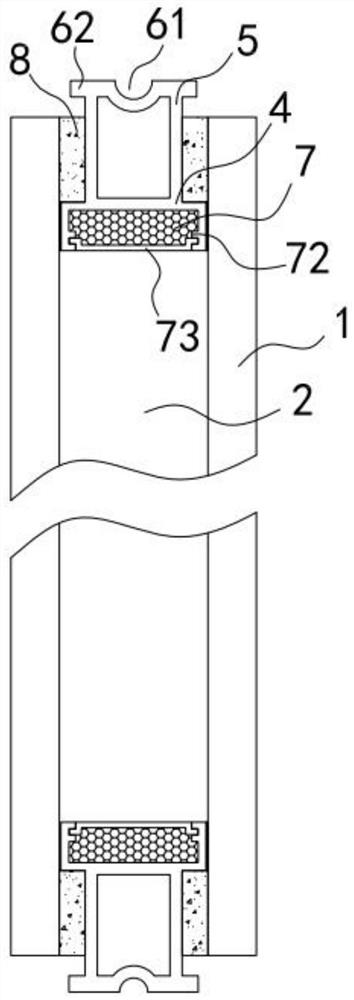

Embodiment 3

[0032] Such as image 3 As shown, the difference between this embodiment 3 and embodiment 1 is that the overall shape of the profile 3 is I-shaped, the structure of the embedded part 4 is simpler, and the force transmission between the extension part 5 and the embedded part 4 is more directly dispersed in the embedded part 4. On the two side walls, the force is more uniform; and more area is reserved for the extended installation part 6, which is convenient for size adjustment and subsequent installation and connection of functional aluminum parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com