A connection structure between steel wire and transmission shaft, surgical robot and method

A connection structure and transmission shaft technology, applied in the field of medical equipment, can solve the problems of single transmission torque or push-pull force, complex structure, long time consumption, etc. of the transmission connection mechanism, and achieve the effects of labor-saving operation, convenient and fast process, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0061] This embodiment discloses a surgical robot, which is provided with the connection structure between the steel wire and the transmission shaft described in Embodiment 1, the transmission shaft is connected to the drive mechanism, and the drive mechanism can drive the transmission shaft to rotate around its own axis and to rotate along its own axis. For linear motion in the direction, the drive mechanism can be an existing drive mechanism for surgical robots, and its specific structure will not be described in detail here.

Embodiment 3

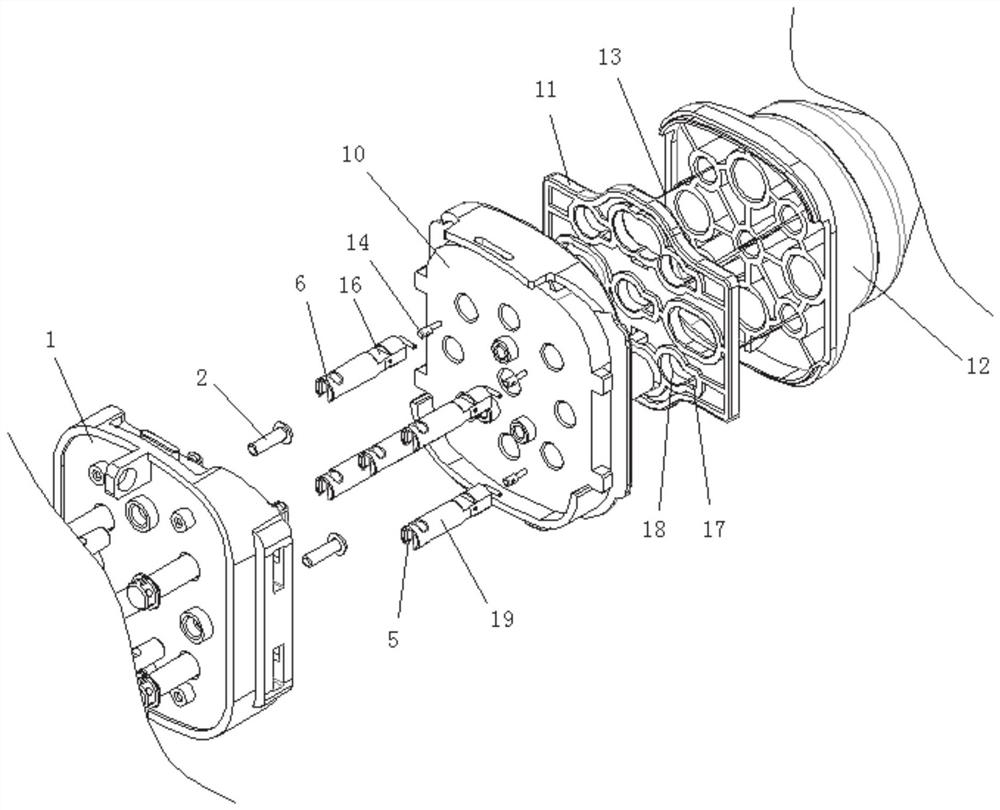

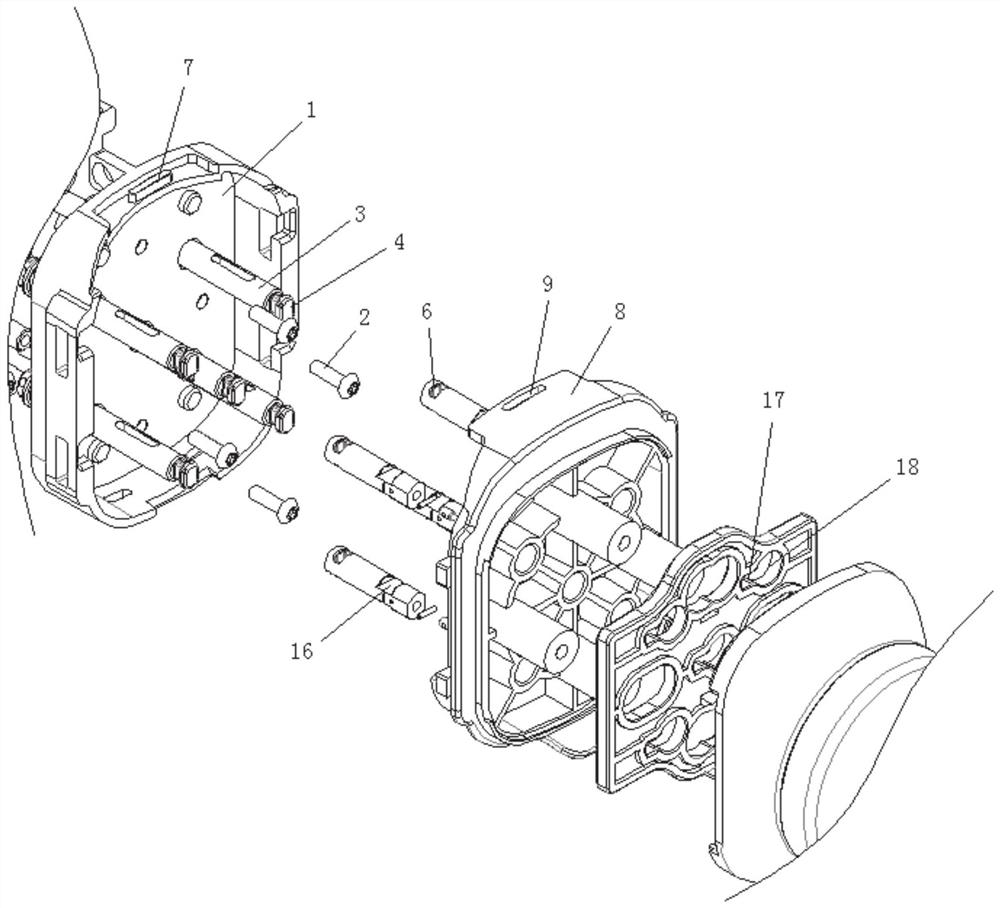

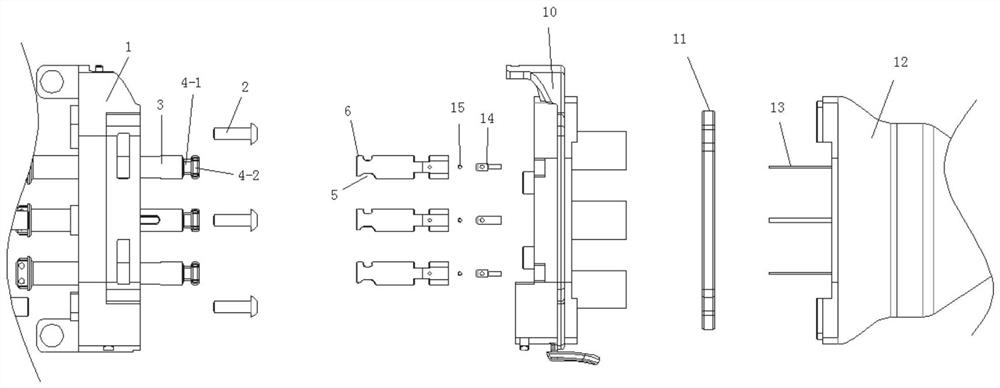

[0063] This embodiment discloses a method for connecting the transmission shaft and the steel wire connection structure described in Embodiment 1, such as Figure 6-Figure 9 shown, including the following steps:

[0064] After passing the quick-connection shaft through the docking seat and dialing the card in advance, insert the connecting pin fixed with the steel wire into the end of the quick-connection shaft, and lock and fix it with the locking pin. Push the dial, so that the limiting portion of the quick-connect shaft enters the first hole. At this time, the quick-connect shaft is restricted by the first hole and cannot rotate around its own axis or move along its own axis.

[0065] Drive the structural movement composed of the docking seat, pipeline parts, dial card, steel wire rope, and quick-connect shaft, and move from top to bottom, so that the block of the transmission shaft is inserted into the groove, and the second block part extends into the arc-shaped plate Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com