One-way valve

A one-way valve and valve core technology, which is applied to lift valves, valve details, control valves, etc., can solve the problems of easy wear of the sealing surface, the need to improve the oil inlet efficiency, and the small size of the one-way valve, so as to shorten the sealing time. , Increase the durability and improve the effect of the liquid inlet cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

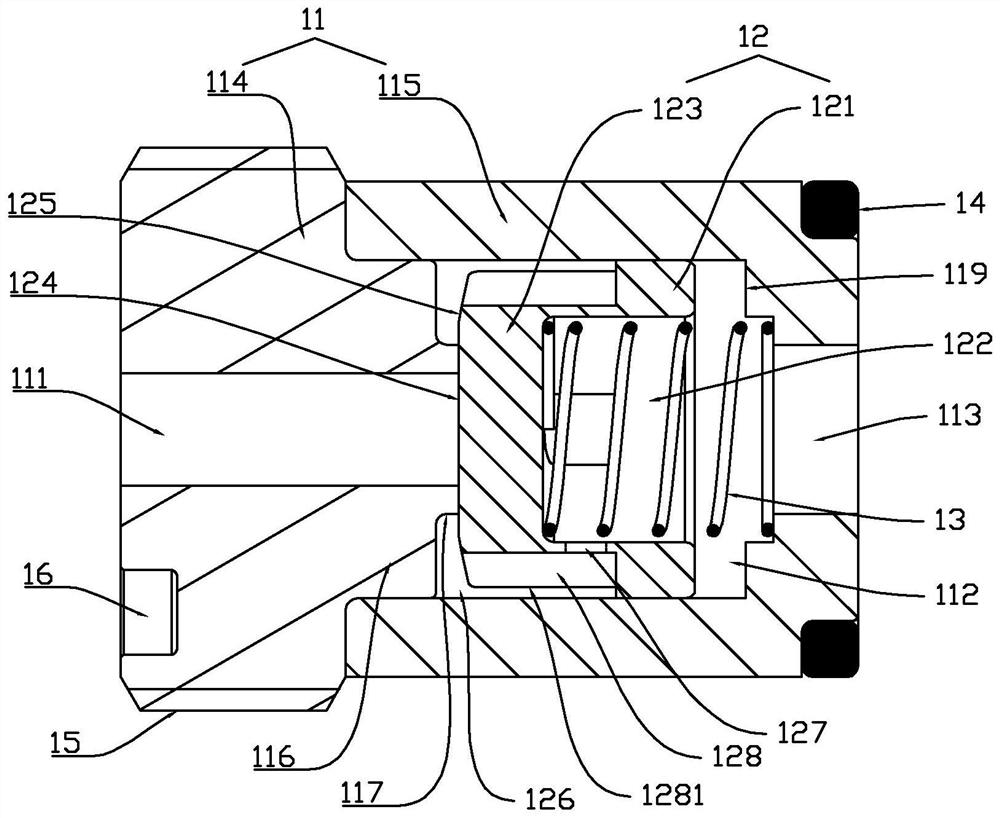

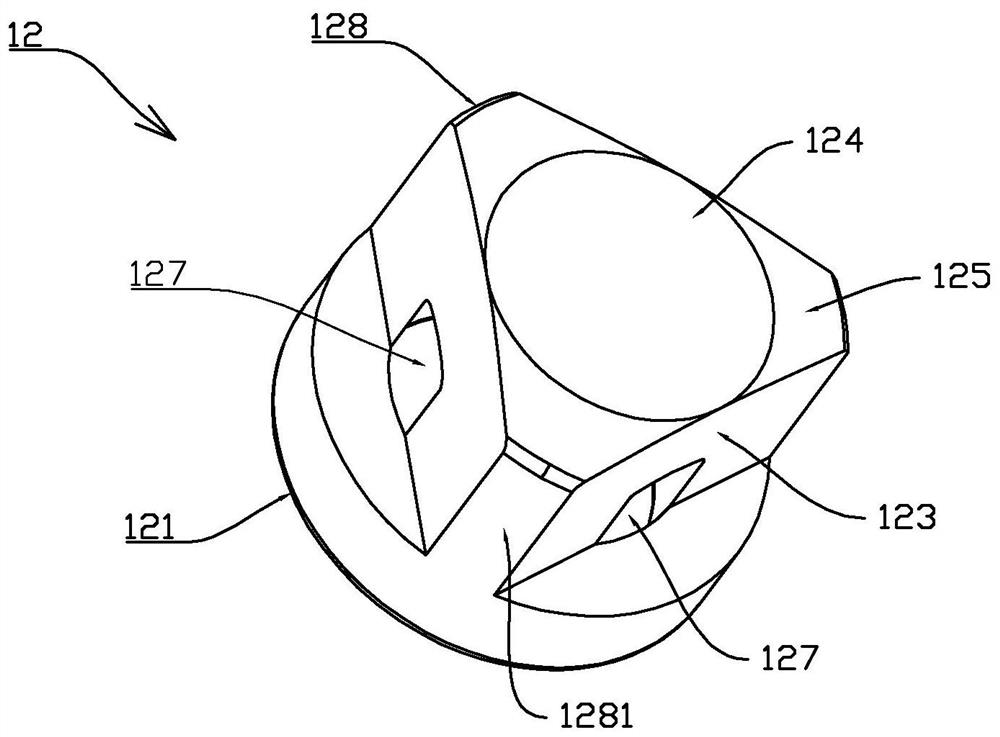

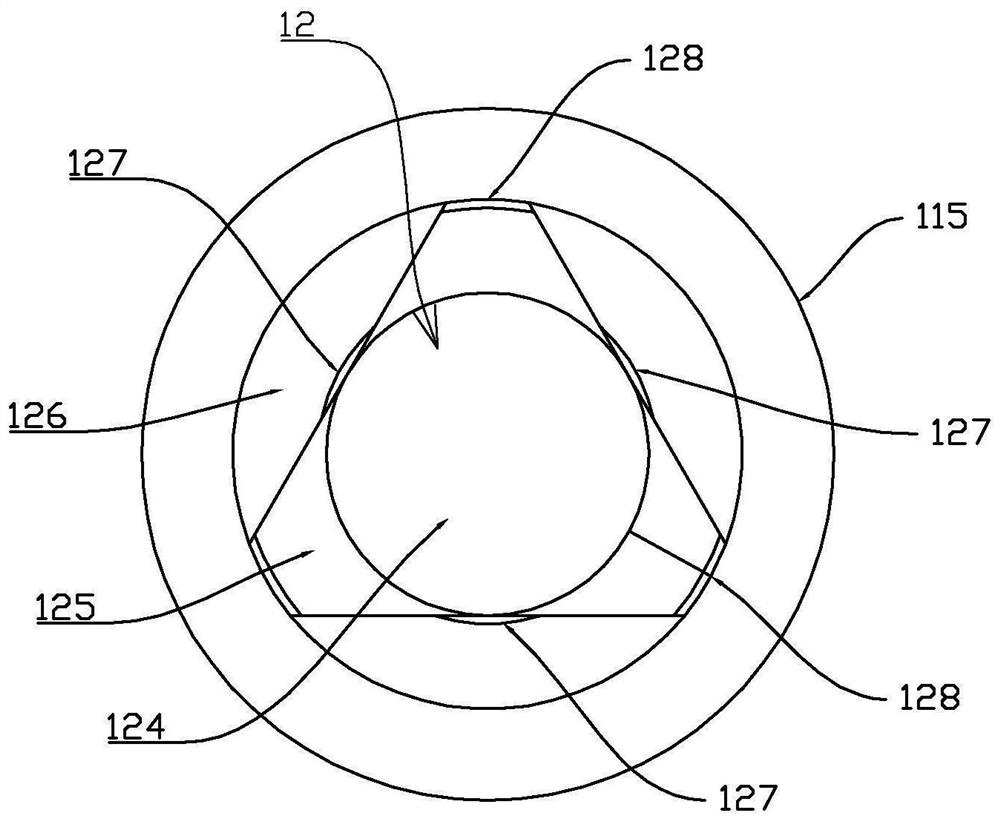

[0046] Such as figure 1 , 4 As shown, a one-way valve, specifically an oil-inlet one-way valve, is mainly used to be installed on the oil circuit of a hydraulic tool, and includes a valve main body 11 , a valve core 12 and a reset member 13 .

[0047] The valve main body 11 includes an oil inlet portion 114 with an oil inlet hole 111 and an oil outlet portion 115 with an oil outlet hole 113. A valve core installation cavity 112 is formed in the oil outlet portion 115, and the oil inlet portion 114 forms a There is a clamping convex ring 116, and the oil outlet part 115 is fixed on the clamping convex ring 116, and realizes sealing installation.

[0048] The valve core 12 is movably installed in the valve core installation cavity 112, the reset member 13 is installed between the valve core 12 and the valve main body 11, and the valve core 12 is sealed or connected to the oil inlet hole 111 through the reset member 13, Realize the function of one-way communication. The reset ...

Embodiment 2

[0061] Such as Figure 5-6 As shown, this embodiment specifically refers to an oil outlet check valve. The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: the sealing ring 14 is provided with an oil inlet portion 114, and the threaded portion 15 is formed In the oil outlet portion 115 , three driving holes for installing tools are opened on the outer end surface of the oil outlet portion 115 .

Embodiment 3

[0063] Such as Figure 7-8 As shown, this embodiment specifically refers to an oil inlet check valve. The structure of the embodiment is basically the same as that of Embodiment 1, the difference lies in the installation position of the sealing ring, specifically, the connection end of the valve body 11 is formed There is an inclined surface, and a sealing groove is provided on the inclined surface, and a sealing ring 14 is installed in the sealing groove. In order to prevent the sealing ring 14 from extrusion misalignment, such as Figure 8 As shown, the angle between the slope and the end surface of the valve body 11 is 120 degrees. This can effectively prevent the threaded portion 15 from loosening and ensure the reliability of the installation position. Meanwhile, the installation structure of the sealing ring is applicable to all the above-mentioned embodiments.

[0064] In addition, the above embodiments can also be applied to products such as pneumatic tools, engines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com