Miniature gas chromatograph for atmospheric pollution detection

A technology of micro-gas chromatography and protective shell, which is applied in the field of micro-gas chromatographs for air pollution detection. It can solve problems such as being vulnerable to bumps, exposed devices, and damaged devices, and achieves convenience in use, increased safety, and extended service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

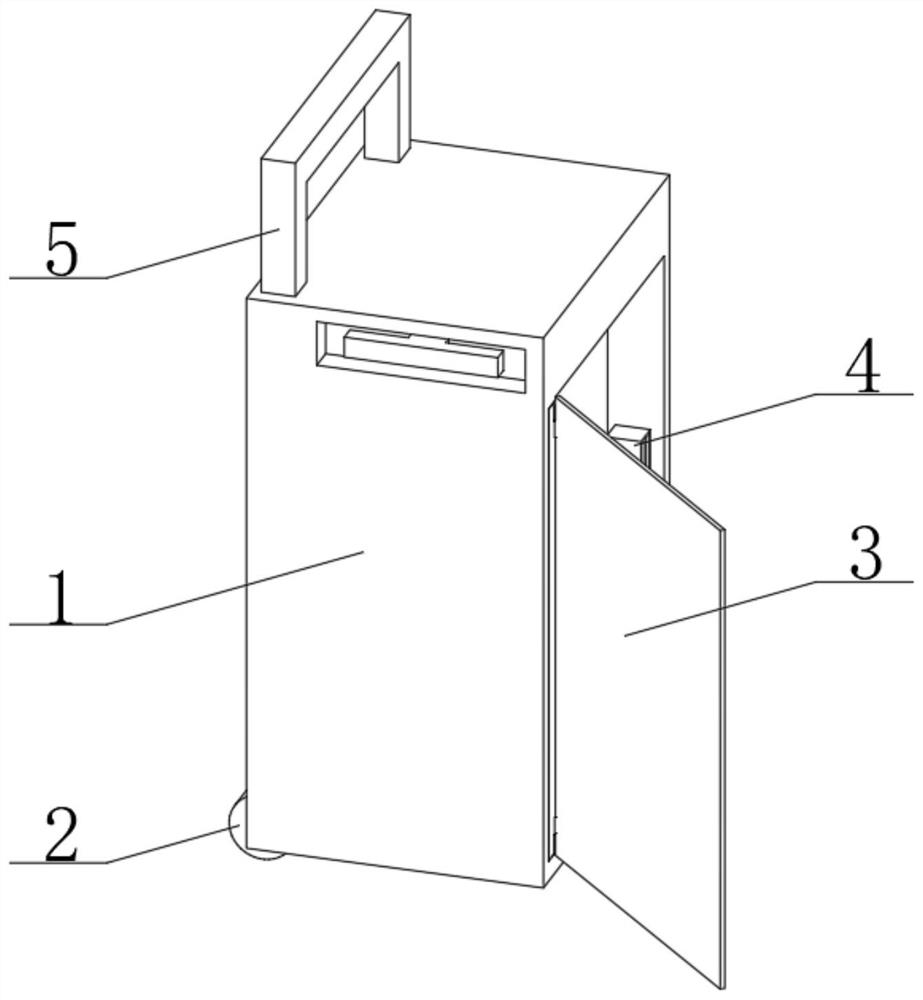

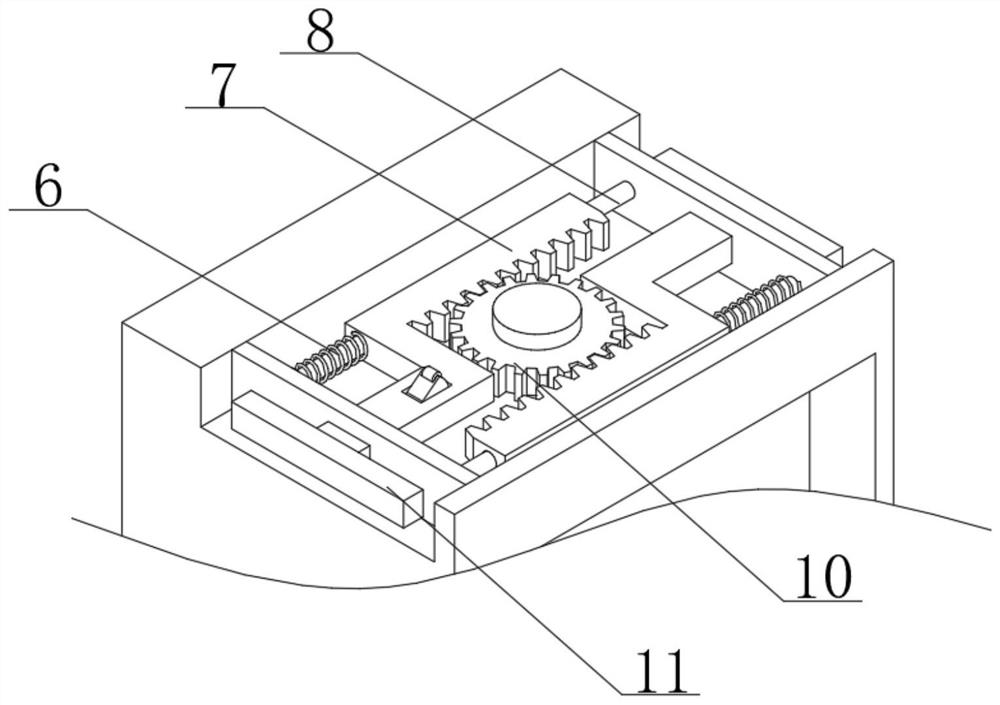

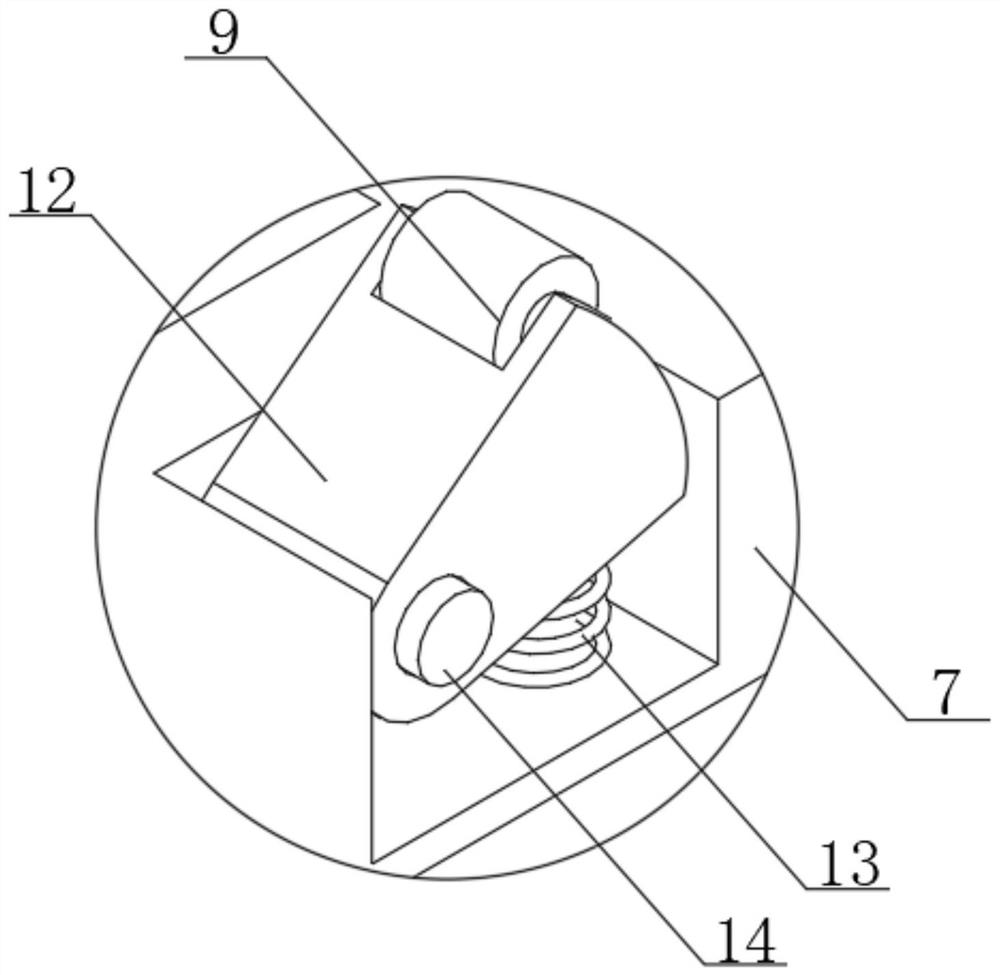

[0030] see Figure 1-3 , a miniature gas chromatograph for atmospheric pollution detection, comprising a protective shell 1, a roller 2 is movably connected to the bottom of one side of the protective shell 1, a telescopic rod 5 is movably connected to the inner side of the protective shell 1, and the top center of the protective shell 1 A rotating toothed plate 10 is rotatably connected at the top of the protective shell 1, and a guide rod 8 is fixedly connected to both sides of the top inner wall of the protective shell 1. One end of the guide rod 8 is sleeved with a rack 7, and the other end of the guide rod 8 is sleeved with a first compression spring. 6. The rack 7 and the protective shell 1 are movably connected by the first compression spring 6. One end of the rack 7 is fixedly connected with a pull rod 11, and one end of the rack 7 is fixedly connected with a second compression spring 13 inside. One end is fixedly connected with an installation shaft 14, the outer slee...

Embodiment 2

[0033] see figure 1 and 4 -6, This embodiment is further optimized on the basis of Embodiment 1. Specifically, one side of the protective shell 1 is provided with a movable groove 17, and one side of the movable groove 17 is fixedly connected to the third compression spring 18. One end of the three compression springs 18 is fixedly connected with the mounting plate 15 .

[0034] Specifically, the door panel 3 is fixedly connected to one side of the mounting plate 15 , and the mounting block 4 is fixedly connected to one side of the inner wall of the protective shell 1 .

[0035] Specifically, a mounting seat 20 is fixedly connected to one side of the door panel 3 , a clamping plate 19 is fixedly connected to one side of the mounting seat 20 , a hanging ring 22 is fixedly connected to the other side of the mounting seat 20 , and the center of the mounting seat 20 is fixedly connected There is a top plate 21 .

[0036] Specifically, one side of the mounting block 4 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com