Thermal power plant operation management and control method and system

A thermal power plant, management and control technology, applied in the direction of general control system, control/regulation system, comprehensive factory control, etc., can solve the problems of low production efficiency in thermal power plants, and achieve the goal of improving production efficiency, improving management and control efficiency, and improving instruction and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

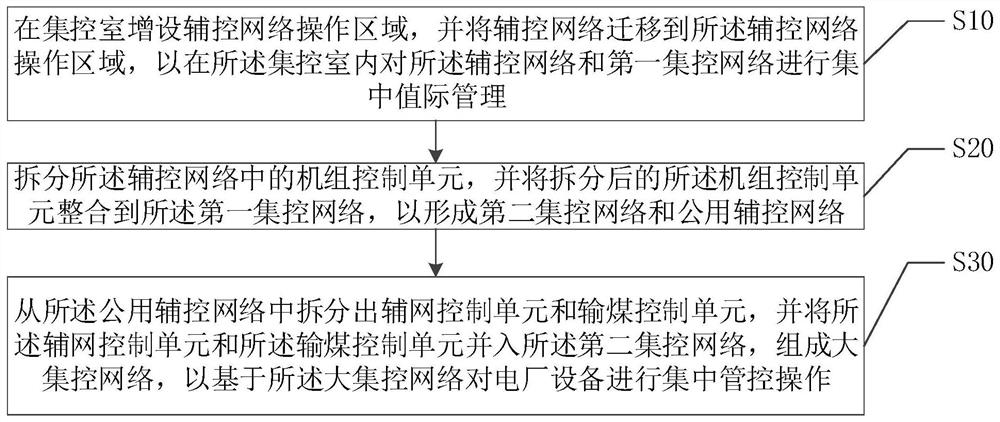

[0043] An embodiment of the present invention provides a thermal power plant operation control method, referring to figure 1 , figure 1 It is a schematic flow chart of an embodiment of the thermal power plant operation management and control method of the present invention.

[0044] In this embodiment, the thermal power plant operation control method includes the following steps:

[0045] Step S10: Add an auxiliary control network operation area in the centralized control room, and migrate the auxiliary control network to the auxiliary control network operation area, so as to centralize the auxiliary control network and the first centralized control network in the centralized control room international management;

[0046] In this embodiment, specifically, relevant staff members rebuild the centralized control room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com