A method and system for optimizing the time window of the master-partner collaborative maintenance plan

A technology of maintenance plan and optimization method, which is applied in the direction of information technology support system, calculation, data processing application, etc., and can solve the problems of equipment maintenance main distribution failing to pass intelligent analysis, distribution network power loss, collaborative processing, etc., to achieve lean improvement The effect of optimizing the management level, reducing the amount of analysis and calculation, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

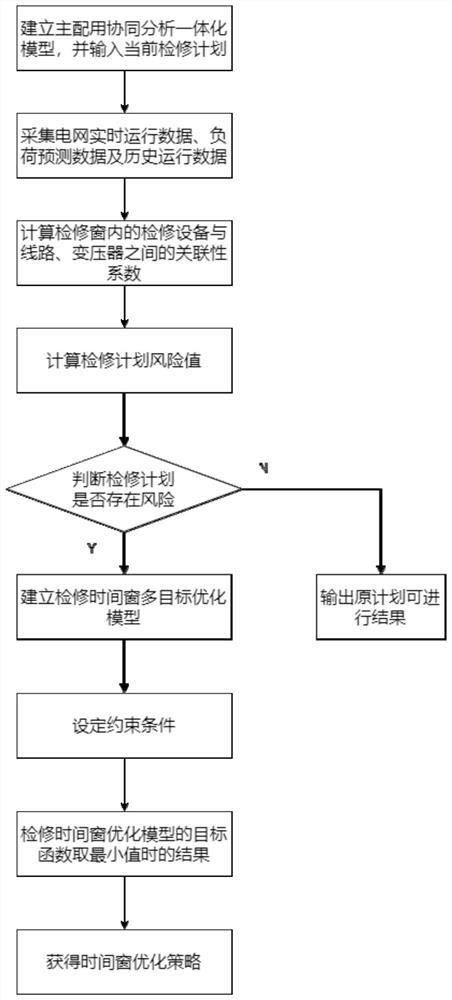

[0065] A method and system for optimizing the time window of a coordinated maintenance plan for main equipment will be described in detail below with reference to the accompanying drawings.

[0066] like figure 1 As shown, a method for optimizing the time window of a main equipment collaborative maintenance plan of the present invention includes the following steps:

[0067] Step 1. Based on the data fusion technology, establish an integrated model of the main and equipment collaborative analysis, and input the current maintenance plan. Specifically, the maintenance plan includes the maintenance start time, the maintenance duration, and the human and material resources occupied by the maintenance. The integrated model of the main and auxiliary cooperative analysis of the present invention can realize the cross-system data sharing in combination with the transparent access service.

[0068] Step 2: Collect the real-time operation data, load forecast data and historical operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com