Storage rack with horizontal shelf capable of vertically moving

A technology of vertical movement and storage racks, which is applied in the direction of furniture accessories, cabinets for storing books, coin-free or similar appliances, etc. It can solve the problems of small drawers, easy tilting of the loading board, and waste of cabinet space, etc., to achieve The effect of increasing storage capacity, reducing energy consumption for lifting and lowering, and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

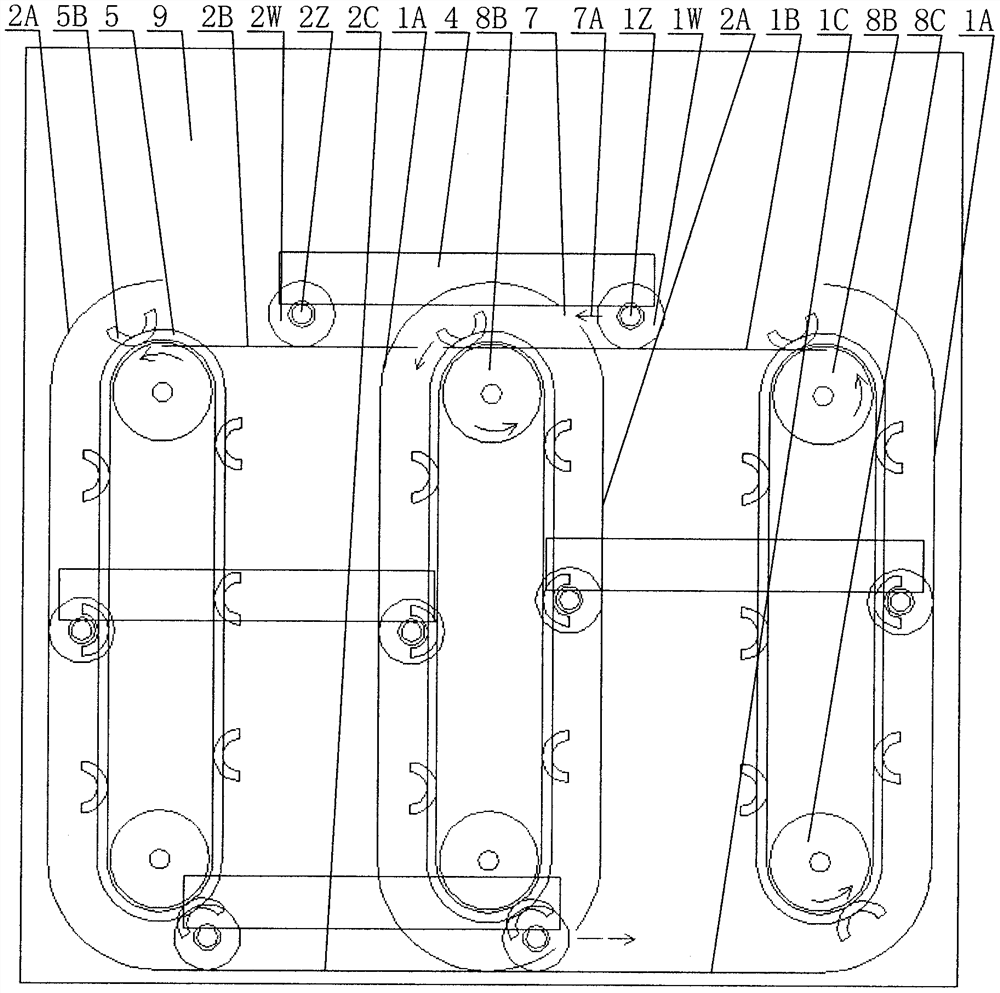

[0044] Embodiment 1: refer to figure 1 and figure 2 . The two sides of frame (9) are equipped with outer rail (1) and inner rail (2) side by side, outer rail (1) outside inner rail (2), two outer vertical rails (1A) of outer rail (1) The upper end and the lower end are smoothly connected to the outer upper rail (1B) and the outer lower rail (1C), and the upper and lower ends of the two inner vertical rails (2A) of the inner rail (2) are gently connected to the inner upper rail (2B) and the inner lower rail (2C ), one end of the outer rail (1) protrudes from one end of the inner rail (2), the other end of the inner rail (2) protrudes from the other end of the outer rail (1), and the two ends of the horizontal shelf (4) are equipped with outer shafts ( 1Z) and the inner shaft (2Z), the outer wheel (1W) is installed at both ends of the outer shaft (1Z), the inner wheel (2W) is installed at both ends of the inner shaft (2Z), and the outer wheel (1W) can move along the outer rai...

Embodiment 2

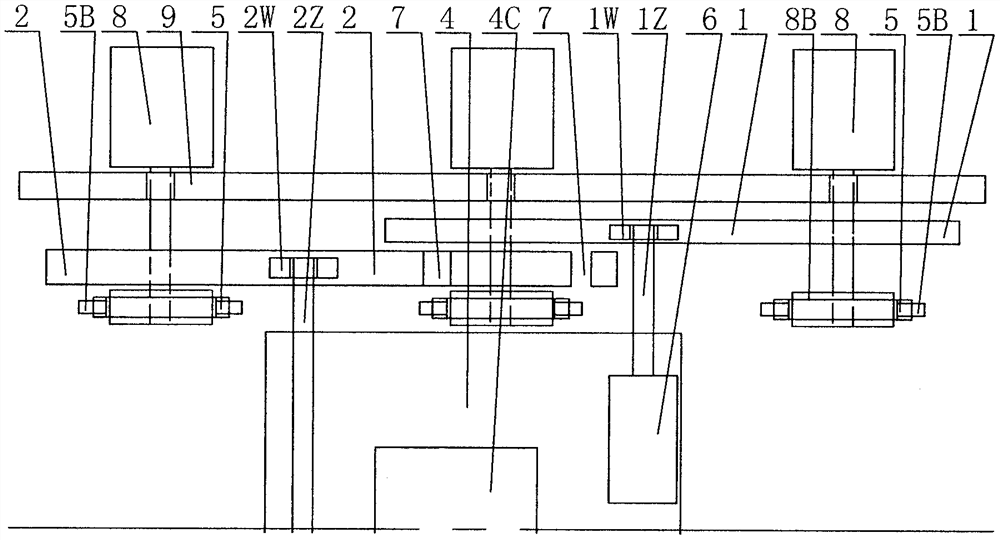

[0046] Embodiment 2: refer to Figure 3 to Figure 10 . For viewing convenience, Figure 7 and Figure 8 No tape (8A). The horizontal shelf (4) is equipped with a drawer (4A), and the belt (5) is a chain (5A). When the horizontal shelf (4) rises or falls, the chain (5A) can connect the outer shaft (1Z) and the inner shaft ( 2Z), the two ends of the inner shaft (2Z) are equipped with a plate (P), and the two ends of the plate (P) can be equipped with an auxiliary inner wheel (2WA), and the auxiliary inner wheel (2WA) can move along the inner rail (2). The lifting motor (8) is connected with the belt (8A), and the belt (8A) is connected with the driven wheel (8C). The outer shaft (1Z) and the inner shaft (2Z) are connected with the motor (6). All the others refer to Example 1.

[0047]When passing through the section (7), two auxiliary inner wheels (2WA) and two inner wheels (2W) contact the inner rail, so that the horizontal shelf (4) smoothly crosses the section (7). The...

Embodiment 3

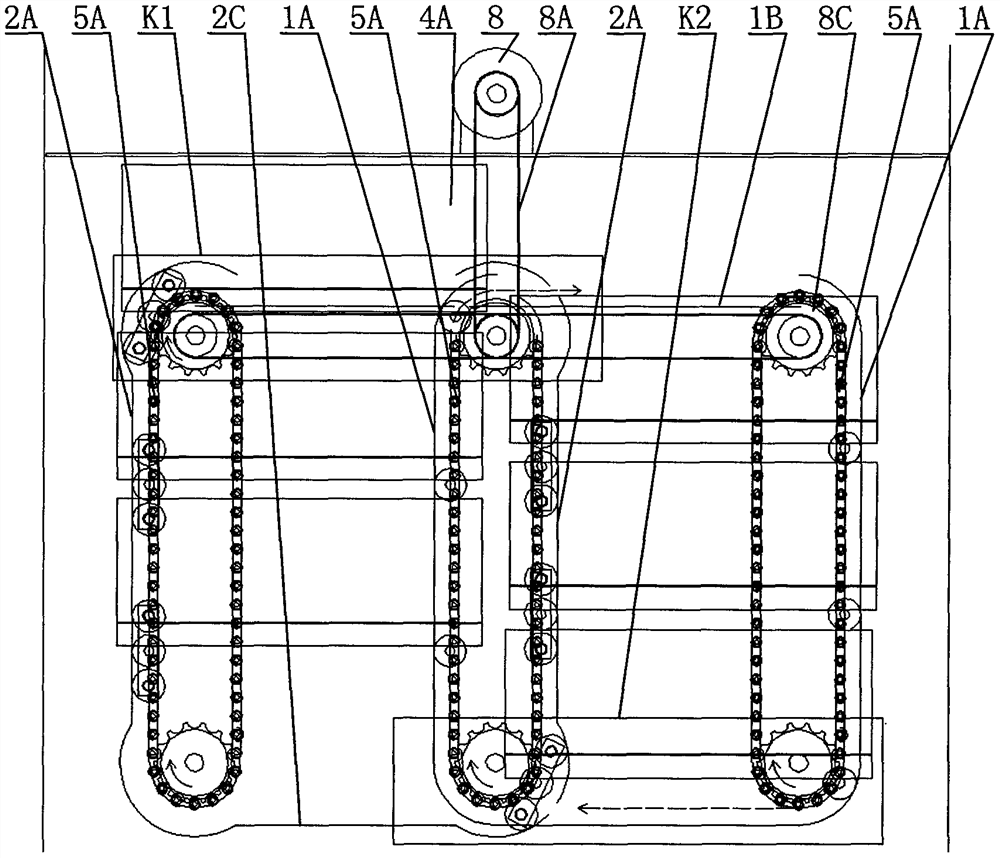

[0048] Embodiment 3: refer to Figure 11 to Figure 13 . For viewing convenience, Figure 11 No tape (8A). The horizontal shelf (4) is equipped with a coaming (4B), with (5) connecting claws (5B), when the horizontal shelf (4) rises or falls, the claws (5B) contact the outer wheel (1W) and the inner wheel (2W) , the two ends of the outer shaft (1Z) are equipped with a plate (P), the plate (P) can be equipped with an auxiliary outer wheel (1WA), and the auxiliary outer wheel (1WA) can move along the outer rail (1). The motor (6) is connected to the driving wheel (6D), and one end of the belt (6E) is connected to the driving wheel (6D), and the other end of the belt (6A) is connected to the driven wheel (6C), and the belt (6E) can be installed on the outer upper rail (1B) and Outer lower rail (1C). All the other with reference to embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com