Method for machining part by using laser melting forming device

A technology of laser melting and laser cladding, applied in the direction of additive processing, additive manufacturing, etc., can solve the problems that parts cannot achieve self-healing effect, and the parameters of defocus amount cannot be determined, so as to achieve uniform structure and performance, and promote Consistent, fast self-healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In the following, the present invention will be more clearly and completely described by means of an embodiment in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the embodiment.

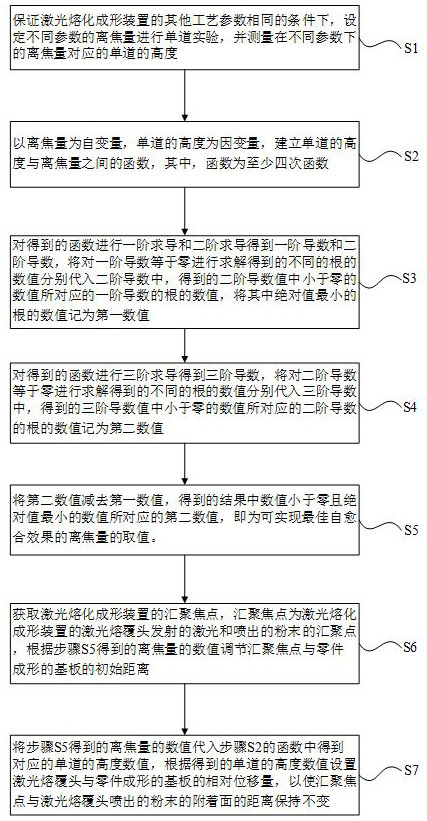

[0049] Such as figure 1 As shown, it is a method for processing parts using a laser melting forming device disclosed in this embodiment, which includes the following steps:

[0050] S1. Under the condition that the other process parameters of the laser melting forming device are the same, set the defocus amount of different parameters to conduct a single-track experiment, and measure the height of the single-track corresponding to the defocus amount of different parameters;

[0051] S2. Using the defocus amount as the independent variable and the height of the single track as the dependent variable, establish a function between the height of the single track and the defocus amount, wherein the function is at least a quartic function;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com