Passenger car

A passenger car and frame technology, which is applied to vehicle parts, superstructures, electric power devices, etc., can solve the problems of affecting the service life of the battery pack and the large vibration amplitude of the battery pack, and achieve weakened vibration, good vibration absorption capacity, and high rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

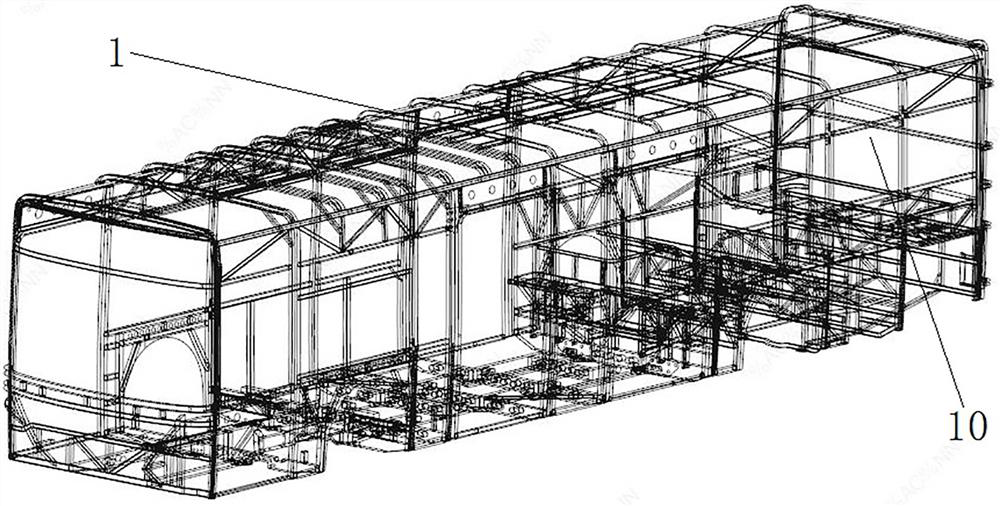

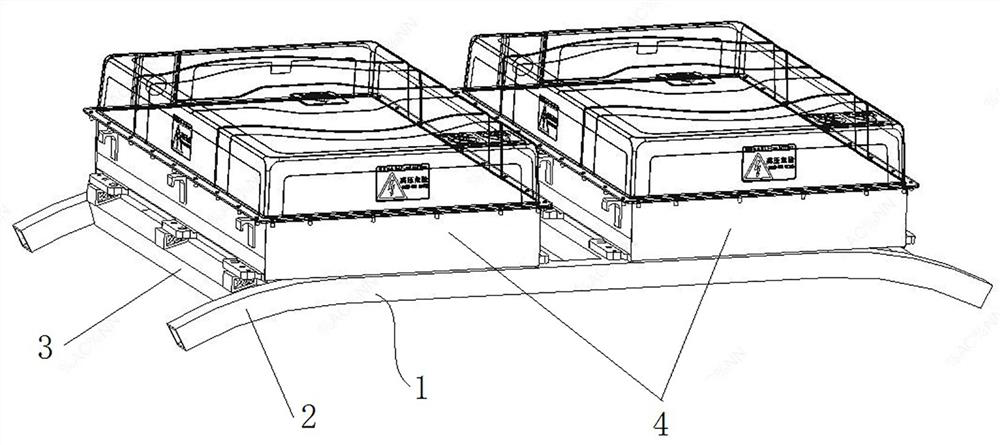

[0031] Specific embodiment 1 of the passenger car of the present invention: the passenger car includes a vehicle frame and a battery pack, such as figure 1 As shown, the top of the vehicle frame is a roof frame 1 , and the side is a side frame 10 , and the battery pack is installed on the roof frame 1 during assembly.

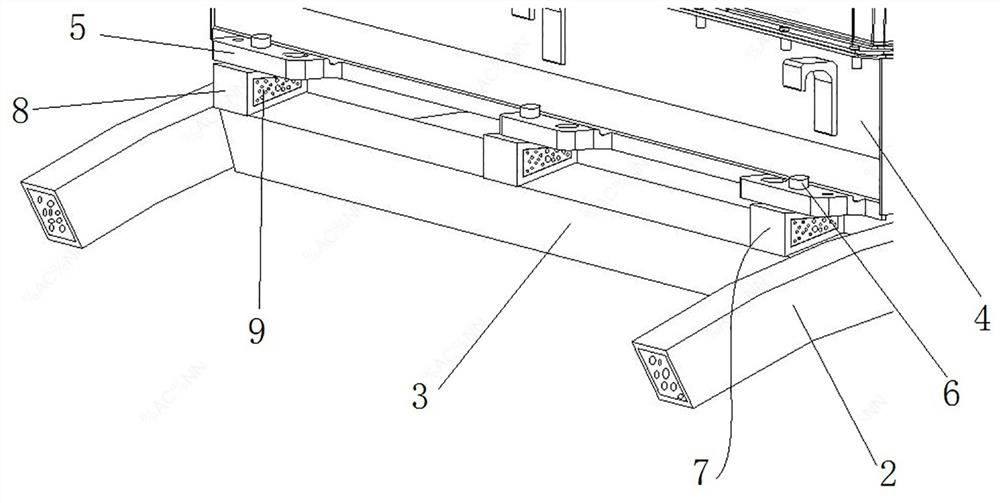

[0032] Specifically, the structure of the roof frame 1 of the vehicle frame is as follows: figure 2 As shown, it includes a cross beam 2 and a longitudinal beam 3, wherein the middle part of the cross beam 2 is straight, and both ends along the width direction of the passenger car are bent into an arc curved toward the side wall frame 10, so that the two ends of the roof frame 1 are Arc-shaped structure, the roof frame 1 is connected with the side frames on both sides of the vehicle frame 1 through the arc-shaped structures at both ends, so that there is a circular arc transition between the two sides of the vehicle body and the top surface.

[0033] Along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com