Method for preparing three-axis concentric nanofiber based on controllable drug release

A nanofiber and drug technology, which is applied in the field of triaxial co-core nanofiber preparation, can solve the problems of drug release depending on the degradation rate, the difficulty of drug release and degradation rate, and the inability to meet the needs of long-acting drug efficacy, and achieve excellent biocompatibility. compatibility with organic polymers, excellent biocompatibility and spinnability, and the effect of improving the efficiency of drug use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

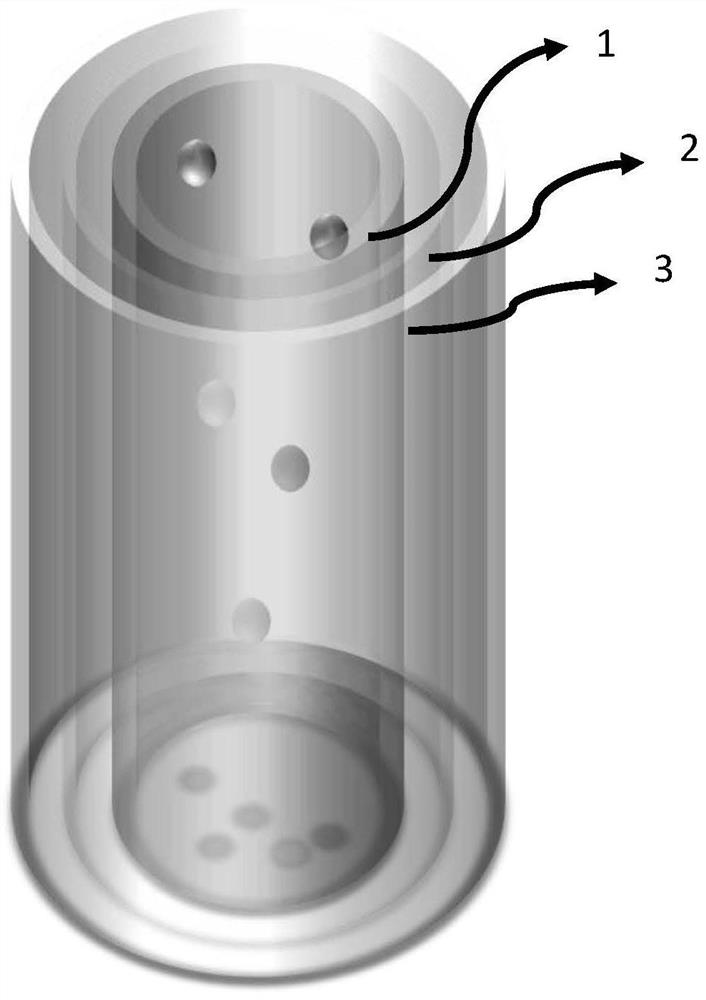

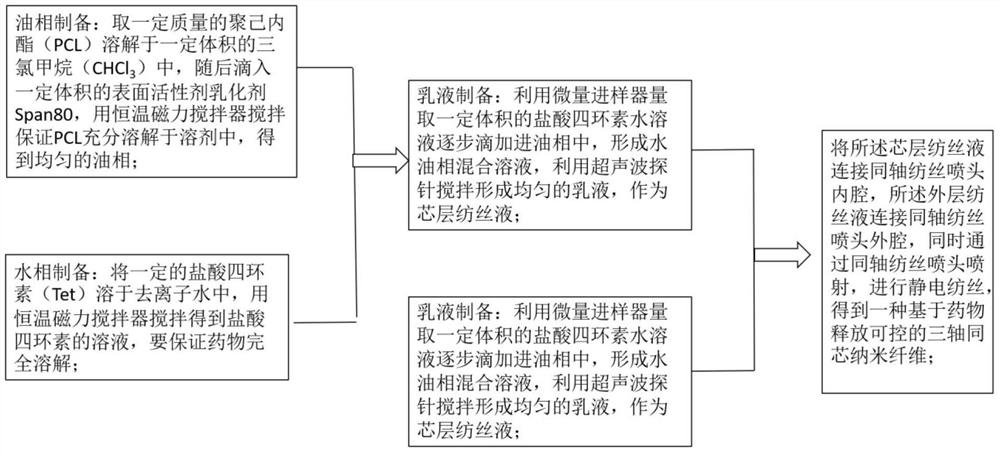

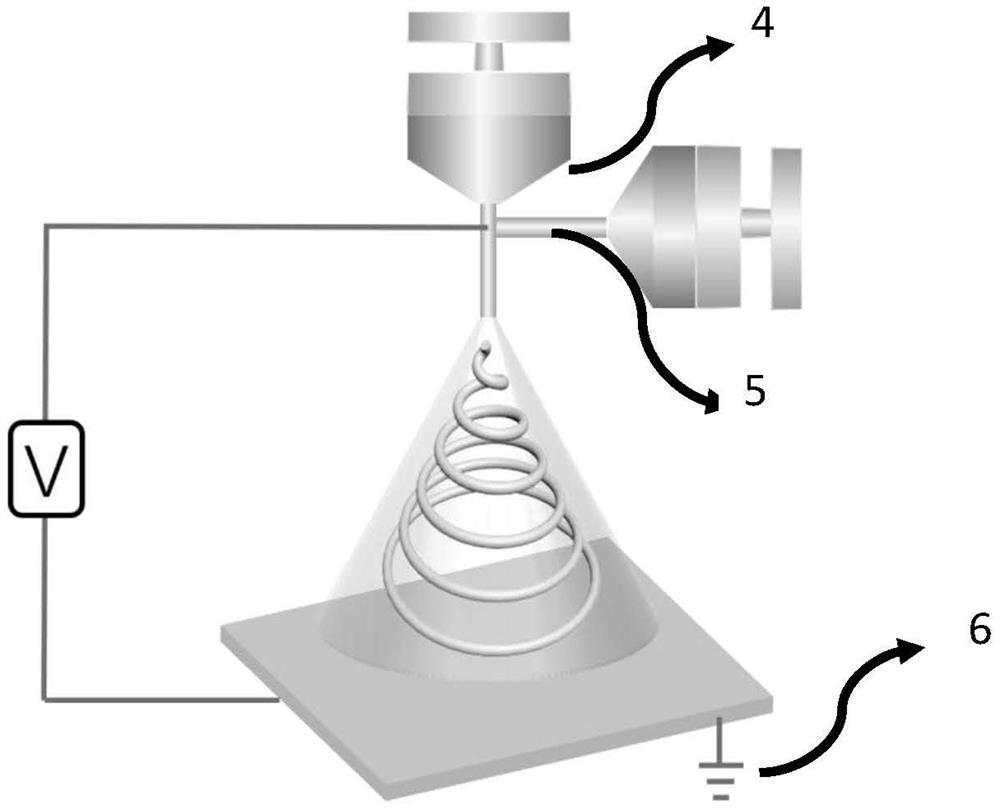

[0035] Such as figure 2 As shown, an exemplary method for preparing a triaxial concentric nanofiber based on drug release controllable is described, and the steps are as follows:

[0036] (1) Oil phase preparation: polycaprolactone is dissolved in chloroform, then a certain volume of surfactant sorbitan monooleate is dropped into it, and the rotating speed is 400-700r / min constant temperature magnetic stirring for 2h to obtain the mass Oily phase with a fraction of 8%-10%;

[0037] (2) Water phase preparation: tetracycline hydrochloride is dissolved in deionized water, and the rotating speed is 400-700r / min constant temperature magnetic stirring for 5-10min, until tetracycline hydrochloride is completely dissolved, and tetracycline hydrochloride aqueous solution is obtained. 8%-10%;

[0038] (3) Emulsion preparation: the tetracycline hydrochloride aqueous solution of step (2) is gradually added dropwise into the oil phase of step (1) through a micro-sampler to form a water-oi...

Embodiment

[0043] Preparation of triaxial concentric nanofibers based on controlled drug release, the steps are as follows:

[0044] (1) Polycaprolactone was dissolved in chloroform, then 20 μL of Span80 was added dropwise, and the mass volume fraction of the oil phase was prepared to be 8%, the stirring speed was selected to be 600 r / min, and the stirring time was 2 h.

[0045] (2) Tetracycline hydrochloride was dissolved in deionized water, the tetracycline hydrochloride solution accounted for 8%-10% of the volume fraction of deionized water, the stirring speed was selected to be 600r / min, and the stirring time was 10min.

[0046] (3) The tetracycline hydrochloride aqueous solution is gradually added dropwise into the oil phase to form a core layer emulsion with a water-oil phase volume ratio of 6%, the stirring intensity is 20% amplitude, and the stirring time is 10min.

[0047] (4) Polyvinylpyrrolidone was dissolved in N,N-dimethylformamide to prepare a shell spinning solution with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap