Manufacturing process of breathable bionic structure knitted fabric

A technology of knitted fabric and manufacturing process, which is applied in the direction of knitting, weft knitting, textiles and papermaking, etc. It can solve the problem of not being able to discharge enough sweat to the surface of the fabric, which will cause the clothing to fit on the surface of the human body and affect the Comfort and other issues, to achieve the effect of keeping dry, avoiding discomfort, and quickly dissipating heat and drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

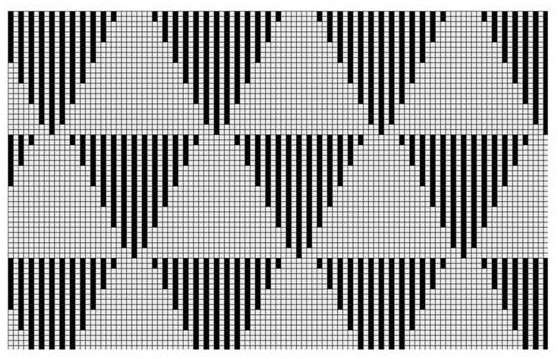

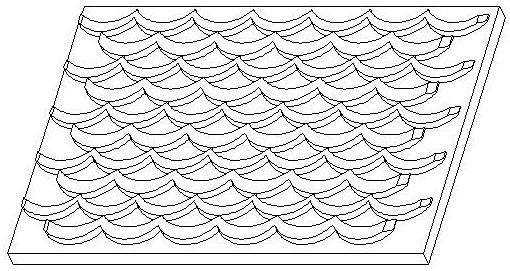

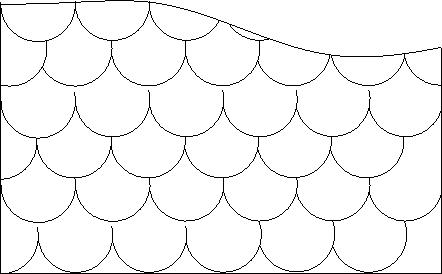

[0022] see Figure 1-4 , the present invention provides a technical solution:

[0023] A manufacturing process of a breathable bionic structure knitted fabric, in which a fabric body is formed by combining tuck loops, floating threads and loop-forming loops according to a certain weaving rule on a knitting machine equipped with a needle selection jacquard function, and the fabric body is integrally woven and formed There is an air layer jacquard breathable structure, and the air layer jacquard breathable structure makes the inner side of the fabric body 1 form a raised cavity, and after wearing, an air layer is formed between the inner side of the fabric body and the human skin 2;

[0024] When the wearer is exercising and sweating, the chamber absorbs the sweat on the surface of the skin and discharges it to the outside of the fabric body. The sweat on the surface of the fabric evaporates continuously, ensuring the dry side of the skin, and the air layer prevents the rapid lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com