Radiator for LED lamp and method for producing radiator for LED lamp

A technology of LED lamps and production methods, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve problems such as difficulty in achieving automation, inability to form air convection, and unsatisfactory heat dissipation effects, etc., to achieve Eliminate welding auxiliary materials, realize continuous uninterrupted and automatic control, and quickly exchange heat with air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

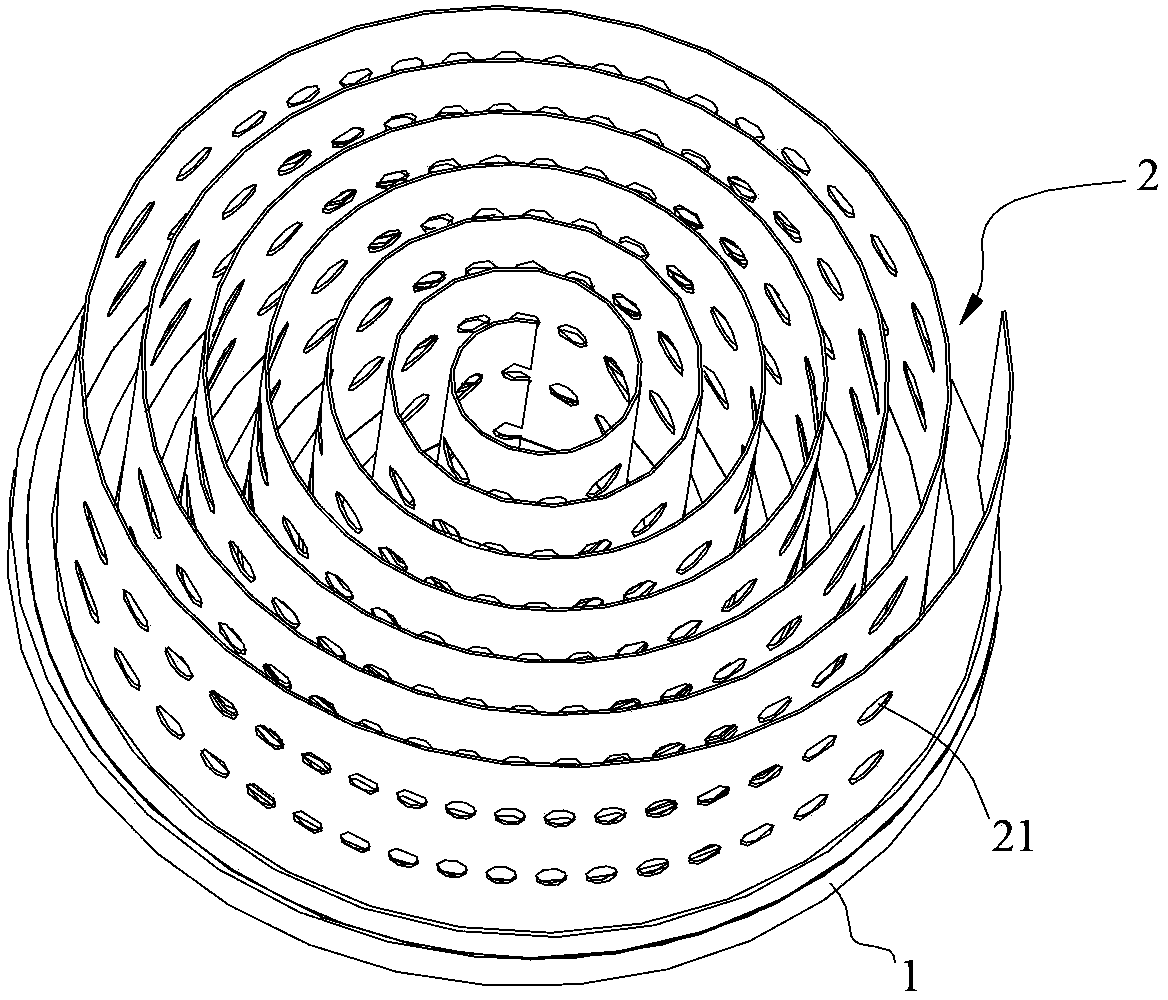

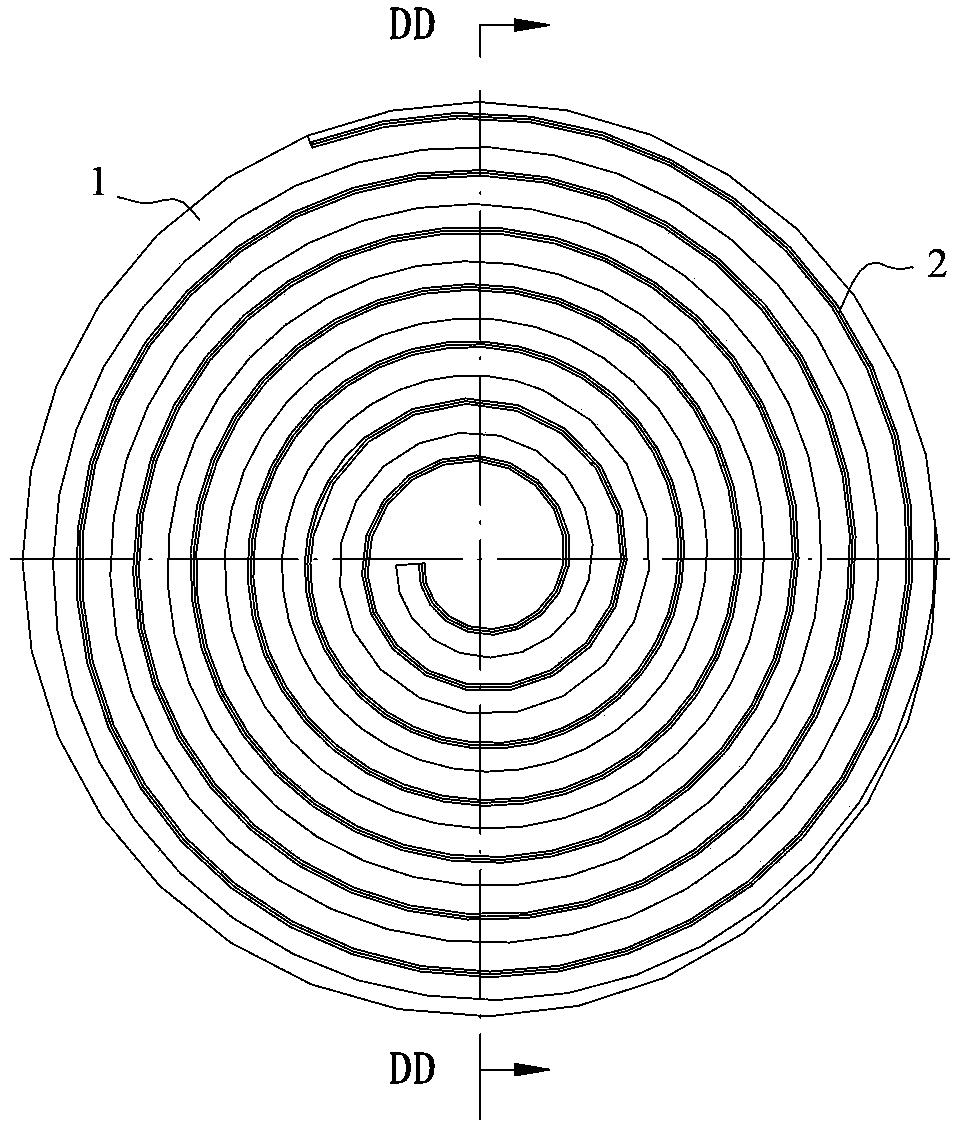

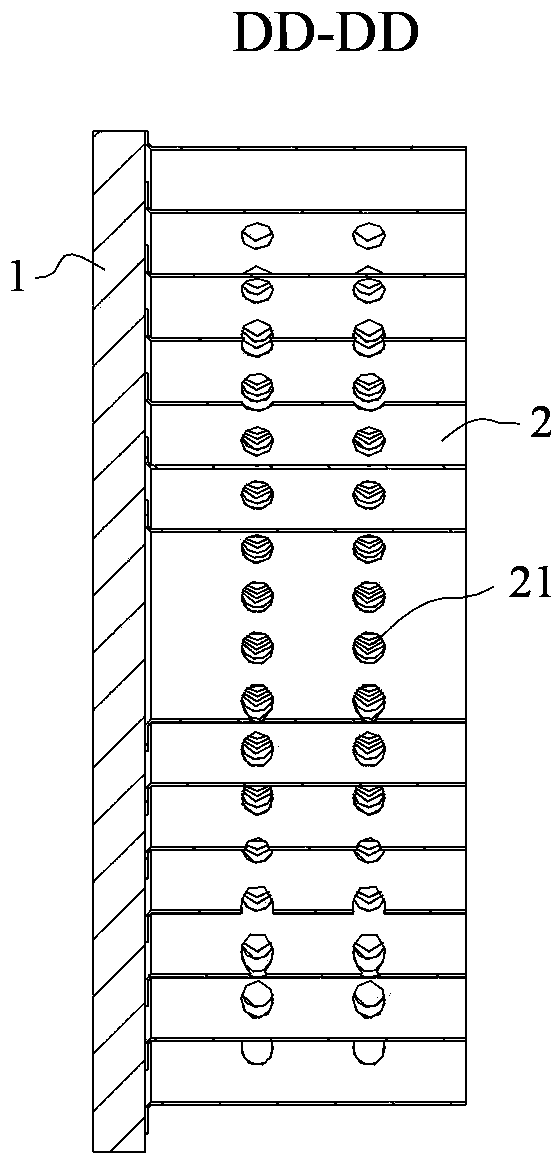

[0030] Such as Figure 1~3 The LED lamp heat sink shown includes a substrate 1 and a heat dissipation device installed on the substrate 1. The heat dissipation device is a scroll 2 formed by spiral rotation and is fixed on the surface of the substrate 1. The rotation axis of the scroll 2 is in line with the Substrate 1 intersects. Such as Figure 4 As shown, after the LED lamp 3 installed on the substrate generates heat, the heat is conducted to the scroll 2 through the substrate 1 , and the heat is dissipated through the spiral gap channel of the scroll 2 .

[0031] The scroll 2 of this embodiment is a strip-shaped thin plate that spirally rotates, which can be made of metal materials such as copper and aluminum, and has a plurality of through holes 21 for convection of cold and hot air on it, and the through holes 21 Arranged at equal intervals on the spiral trajectory of scroll 2. Specifically, the rotation axis of the scroll 2 is perpendicular to the base plate 1 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com