Vegetation concrete ecological slope protection and automatic maintenance method

A vegetation concrete and ecological slope protection technology, applied in chemical instruments and methods, botanical equipment and methods, planting substrates, etc., can solve the problems of lost vegetation concrete slope protection, poor resistance to rain erosion, water and soil erosion, etc., to increase the resistance to rainwater The effect of flushing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

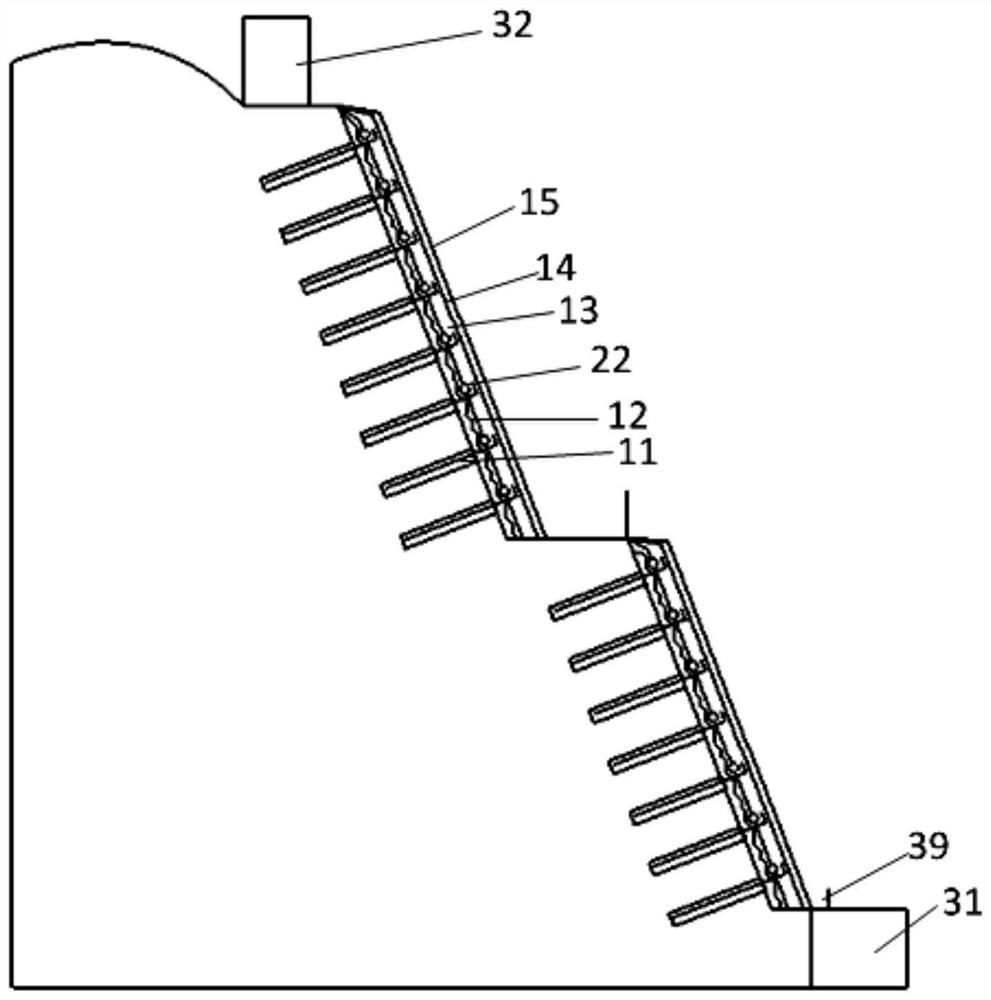

[0057] The difference from Practical Example 1 is that in the present embodiment, the grass-roots vegetation concrete 13 in step S7 is based on the proportion of solids: 0.9m 3 Planting soil: 80kg Cement: 0.1m 3 Humus: 50kg of greening additives, mixed with an appropriate amount of water; step S8 surface layer vegetation concrete 14 is based on the proportion of solids: 0.9m 3 Planting soil: 50kg Cement: 0.1m 3 Humus: 40kg of greening additives, mixed with an appropriate amount of water and stirred.

Embodiment 3

[0059] Compared with Example 1, the difference is that in this embodiment, the grass-roots vegetation concrete 13 in step S7 is based on the proportion of solids: 1m 3 Planting soil: 90kg Cement: 0.15m 3 Humus: 60kg of greening additives, mixed with an appropriate amount of water; step S8 surface layer vegetation concrete 14 is based on the proportion of solids: 1m 3 Planting soil: 60kg Cement: 0.15m 3 Humus: 50kg of greening additives, mixed with an appropriate amount of water and stirred.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com