A thermal imaging target

A thermal imaging and heat technology, applied to targets, offensive equipment, etc., can solve the problems of inability to calibrate and test thermal imaging sights, not to mention measuring and reflecting shooting results, and no easy-to-use target paper, etc. Convenience, convenience, economy, hidden fire safety hazards, no effect of open fire safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following describes in detail the embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar elements or elements having the same or similar functions throughout. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

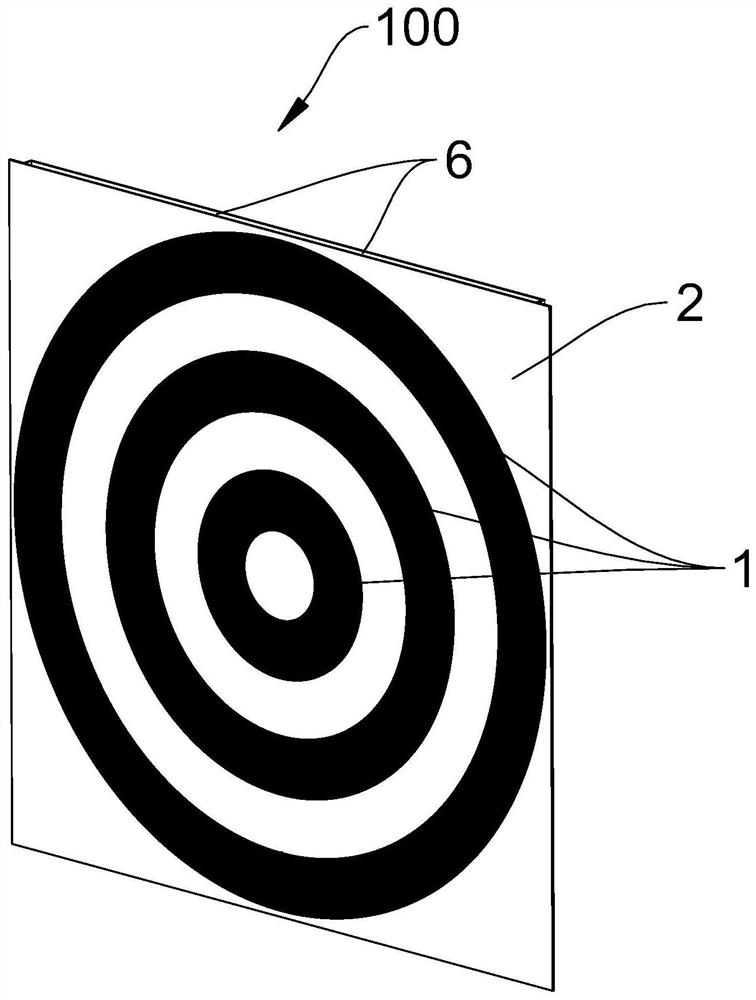

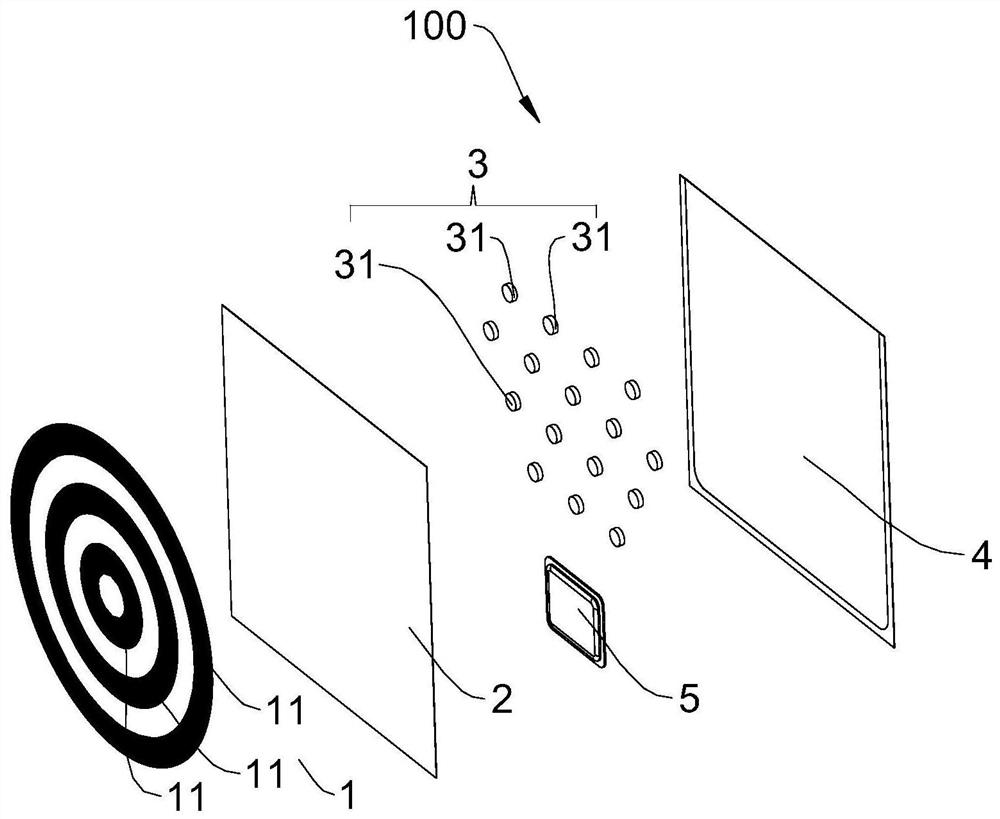

[0032] Please refer to Figure 1 to Figure 2 , which is a thermal imaging target 100 provided by the present invention, which is used for shooting training, and includes a heat insulation layer 1 , a heat conduction layer 2 , a flow guide layer 3 , a bottom layer 4 and a self-heating pack 5 .

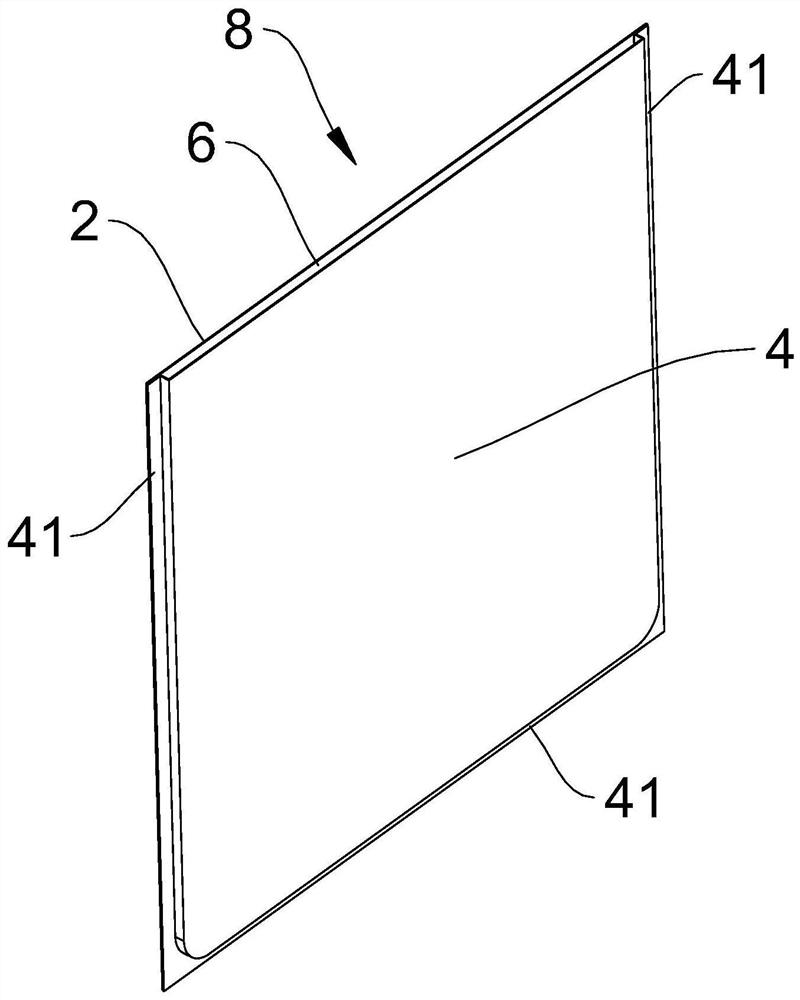

[0033] like image 3 As shown, the thermally conductive layer 2 of the present invention is hermetically connected to the edge of the bottom layer 4 and has an opening 6 at the top end to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com