Equivalent target plate deformation testing device and method based on laser scanning

A deformation test and laser scanning technology, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of cumbersome test steps, low test efficiency, and difficulty in obtaining data and information, and achieve the effect of solving cumbersome test steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

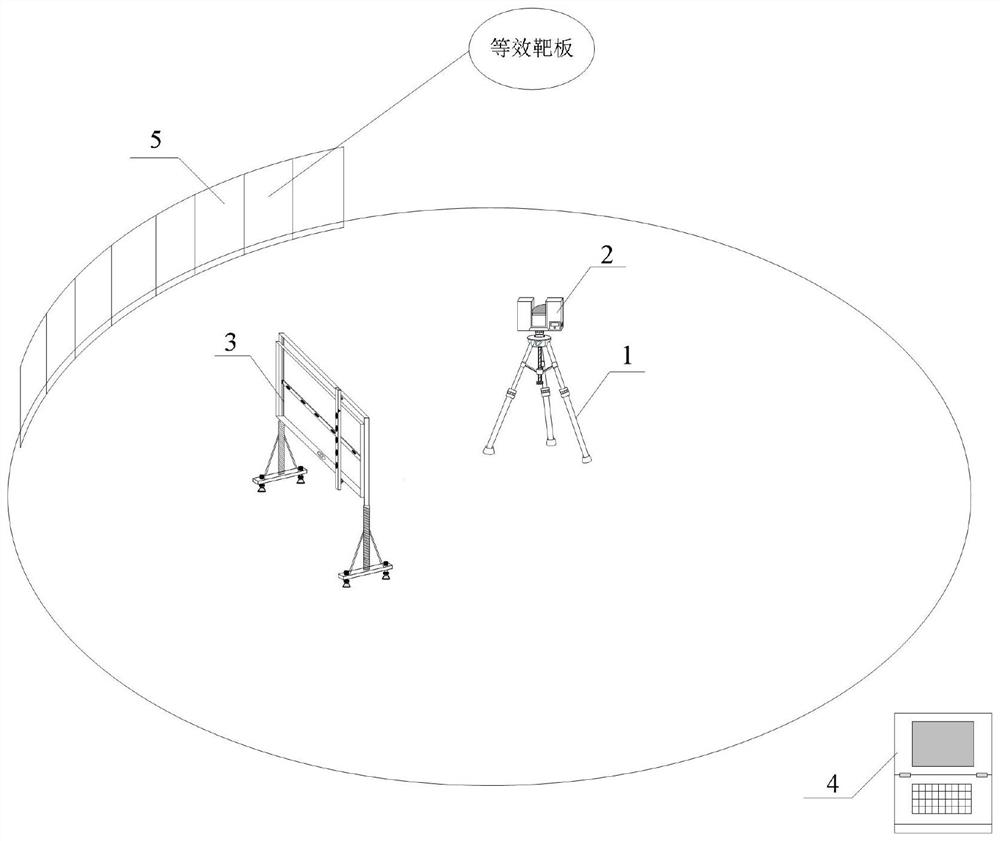

Embodiment 1

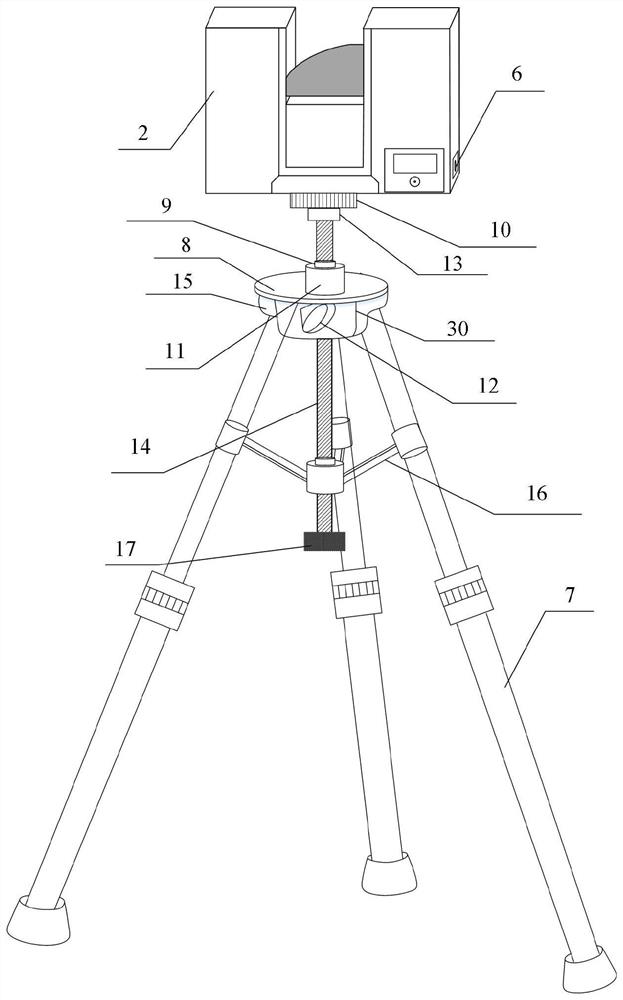

[0043] The console (1) comprises an automatic lifting control module (30) and a tripod (7), the top of the tripod (7) is equipped with the automatic lifting control module (30), and the automatic lifting control module A circular platform (8) for receiving the laser imaging scanner (2) is installed above (30). The central part of the automatic lifting control module (30) and the circular platform (8) is provided with through holes, and the screw rod (14) is vertically screwed in the two through holes, and the automatic lifting control module (30) side A locking knob (12) abutting against the screw rod (14) is arranged on the surface;

[0044] The gear structure (9) controlled by the motor (11) is installed on the outside of the screw (14) above the circular platform (8), and the speed reducer (13) is installed on the outside of the screw (14). The top is provided with a fixed knob (10) to adjust the laser imaging scanner (2);

[0045] The screw rod (14) located below the aut...

Embodiment 2

[0047] The structure of the calibration target frame 3 includes a calibration plate surface 18, a calibration rod 19 and a support frame 20, and the support frame includes a spiral lift rod 21 and a base 22, and the spiral lift rod 21 is fixed above the base 22. Calibration plate surface 18 is installed on two described bracing frame 20 tops, and described calibration plate surface 18 surface is provided with scale 23, adjusts the position of described calibration bar 19 by pulley 24 sliding on described calibration plate surface 18 surface, and described calibration plate surface The rod 19 moves along the scale 23, the surface of the calibration target frame 3 is respectively provided with leveling blisters 25, and the bottom of the calibration target frame 3 is equipped with four adjustment balance seats. The adjusting balance seat includes a knob (26), a bottom angle (27), a fixing nut (28) and a stud (29), the base is provided with mounting holes, and the top of the bottom...

Embodiment 3

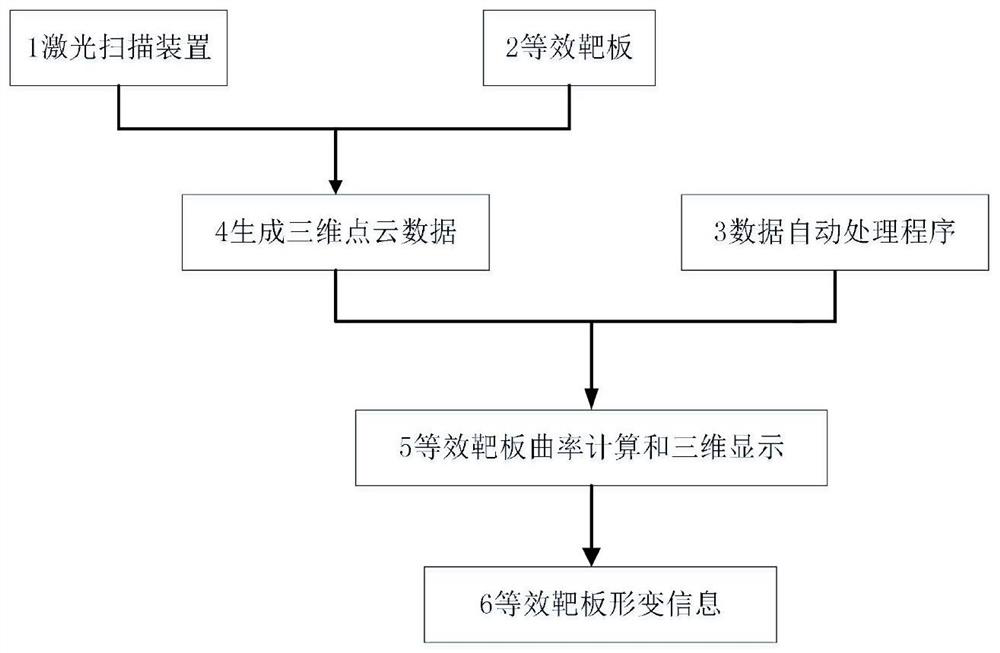

[0049] A kind of testing method of equivalent target plate 5 deformation testing device based on laser scanning, it is characterized in that, comprises the following steps:

[0050] S1: setting the relative position of the laser imaging scanner 2 and the equivalent target plate 5;

[0051] S2: setting a spatial coordinate system through the laser imaging scanner 2 to obtain three-dimensional data in the scanning area;

[0052] S3: Segment the image of the equivalent target plate 5 by using the method of maximum variance between classes, and obtain the three-dimensional data of the area where the equivalent target plate 5 is located;

[0053] S4: Calculate the deformation curvature of the equivalent target plate 5;

[0054] S5: According to the three-dimensional coordinate information of each part of the equivalent target plate 5, the surf function of matlab is used to fit a three-dimensional curved surface, and the three-dimensional reconstruction display of the deformation e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com