Seabed vacuum pipeline with preset sonar sensors, and installation method thereof

A technology of vacuum pipes and sensors, which is applied in the directions of sound wave re-radiation, instruments, and measuring devices. It can solve problems such as weak structural matching, waste of secondary construction, and inconsistent standards, and achieve comprehensive cost reduction. High installation quality, The effect of extending the detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

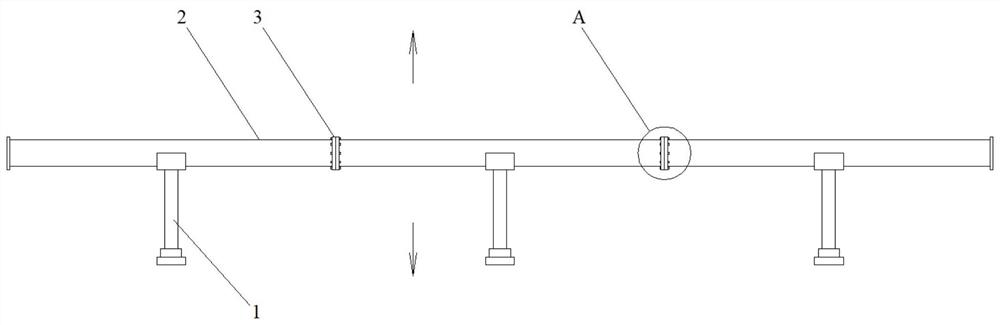

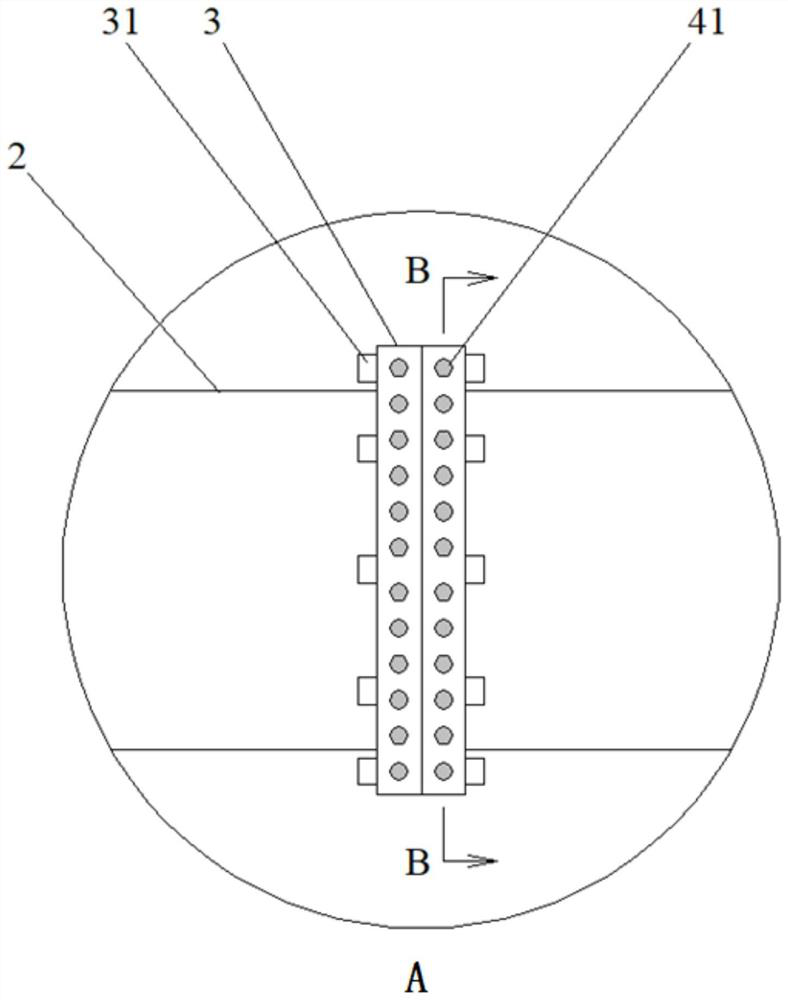

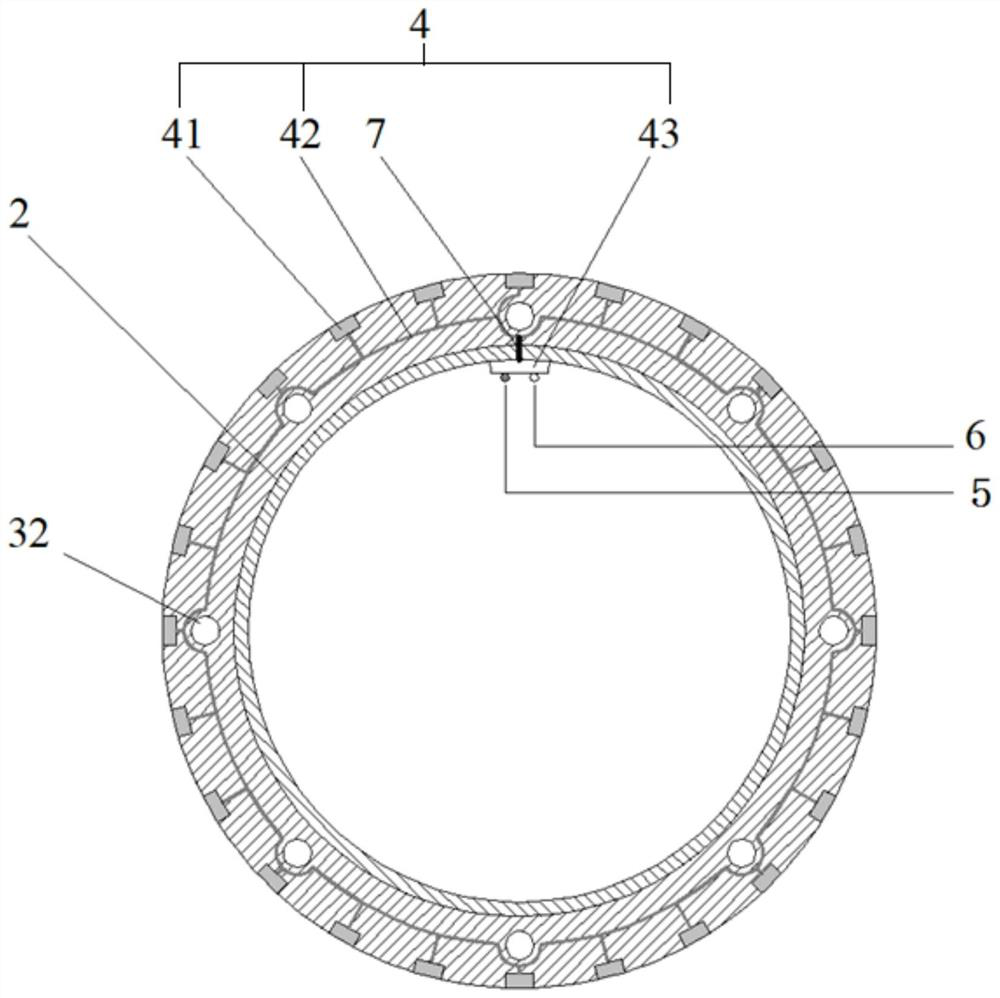

[0040] Such as figure 1 and figure 2 as shown, figure 1The upward direction of the middle arrow is the sea surface, and the downward direction of the arrow is the seabed. The present invention provides a submarine vacuum pipeline with preset sonar sensors, which includes at least two sets of pipe sections 2 fixedly installed on the top of the pipe pier 1, and each set of pipe sections 2 is two Both ends are prefabricated with flanges 3 for connection, and multiple sets of sonar sensors 4 are pre-installed on the pipe section 2, and each set of sonar sensors 4 includes integrated active sonar sensors and passive sonar sensors arranged at even intervals, and each set of integrated active sonar sensors and Passive sonar sensors all include a transducer 41 for receiving and emitting sound waves, and converting the received sound waves into electrical signals, or converting electrical signals into sound waves for emission, and is installed on the inner wall of the pipe section 2 ...

Embodiment 2

[0051] Such as Figure 5 As shown, the upward direction of the arrow in the figure is the sea surface, and the downward direction of the arrow is the seabed. The present invention provides a submarine vacuum pipeline with preset sonar sensors. The difference from Embodiment 1 is that multiple sonar sensors 4 are uniform The intervals are pre-installed on the upper part of the pipe section 2, and the plurality of sonar sensors 4 are spherical.

[0052] The installation method of the submarine vacuum pipeline of the preset sonar sensor specifically includes the following steps;

[0053] Step 1: When the pipe section 2 is manufactured in the factory, first install each set of preset cylindrical sonar sensors 4 on the upper part of the pipe section 2, and lead the wiring into the pipe section 2 through the vacuum terminal 7, and then connect each set of sonar sensors 4 to the upper part of the pipe section 2. The integrated circuits 43 are installed on the inner wall of the pipe ...

Embodiment 3

[0057] Such as Figure 6 As shown, the upward direction of the arrow in the figure is the sea surface, and the downward direction of the arrow is the seabed. The present invention provides a submarine vacuum pipeline with preset sonar sensors. The difference from Embodiment 1 or Embodiment 2 is that each The sonar sensors 4 are correspondingly installed in a sonar base on the prefabricated pipe section 2 .

[0058] The installation method of the submarine vacuum pipeline of the preset sonar sensor specifically includes the following steps;

[0059] Step 1: When manufacturing the pipe sections 2 in the factory, first prefabricate the sonar base on each group of pipe sections 2, and pre-embed the vacuum terminal 7, and fix the integrated circuit 43 on the inner wall of each group of pipe sections 2, for each group of pipe sections The exposed integrated circuit 43 and its vacuum terminal 7 are used for temporary waterproof protection.

[0060] Step 2: Before launching each gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com