Electric control color matching glass

A glass and electric control technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of electrode discoloration function attenuation, short cycle life, uneven discoloration, etc., to simplify the production process, improve production efficiency, and uniform color good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

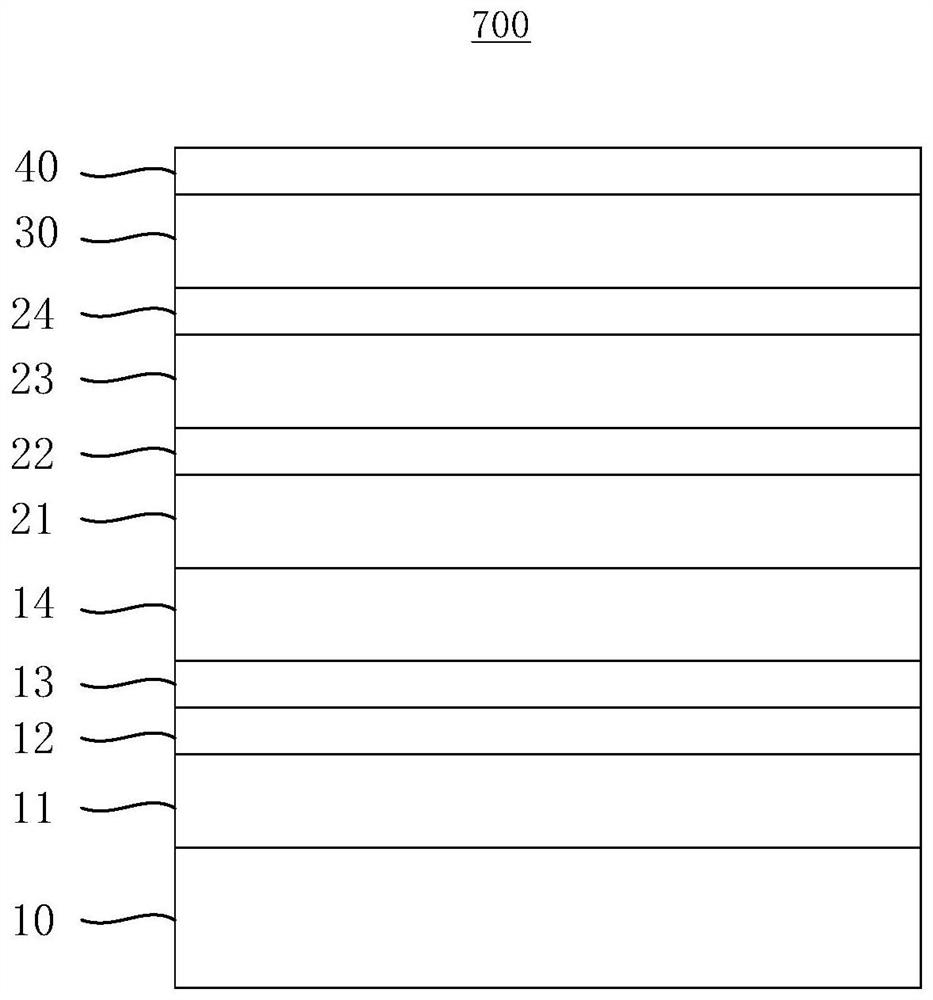

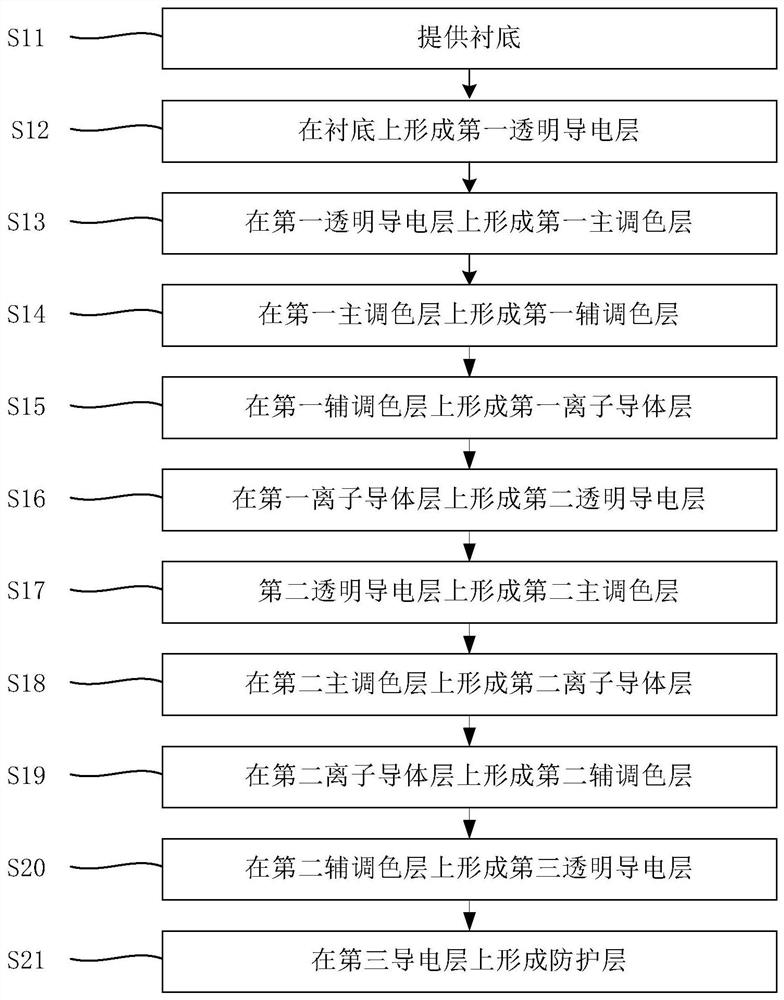

[0027] In addition, the embodiment of the present invention also provides a method for preparing an electronically controlled tinting glass, for example, for preparing the aforementioned electronically controlled tinting glass 700 . The preparation method of electronically controlled tinted glass, for example, comprises the steps of:

[0028] S11: providing a substrate. Clean and dry the substrate.

[0029] S12: forming a first transparent conductive layer on the substrate. Specifically, the substrate is heated to a preset temperature, the range of the preset temperature is, for example, 280-300°C, and one or a combination of at least two of FTO, ITO, IGZO, AZO, GZO, and Ag is used as the target The material is deposited under a preset vacuum sputtering pressure to obtain the first transparent conductive layer. The preset vacuum sputtering pressure is, for example, 1.0E -3 ~9.0E -3 mbar. Preferably, the first transparent conductive layer may also be a pre-prepared conduc...

specific Embodiment

[0043] An electronically controlled toning glass, the film layer structure from the substrate to the outside is: substrate / ITO(150nm) / WMoOx(200nm) / NiVOx(80nm) / Li(40nm) / ITO(150nm) / WMoOx(200nm) / Li(40nm) / NiVOx(80nm) / ITO(120nm) / Si 3 N 4 (20nm).

[0044] The process of preparing this electronically controlled tinting glass is as follows:

[0045] (1) The substrate is cleaned and dried, laser scribed, then cleaned and dried, and placed in a vacuum sputtering area;

[0046] (2) Deposit the ITO layer on the substrate by means of magnetron sputtering, the target used is an ITO rotating target, the power supply is DC or an intermediate frequency power supply with a frequency of 2000-40000Hz, the power is 1-30KW, and the process gas is argon , deposited at a temperature of 290°C;

[0047] (3) The WMoOx layer is deposited on the ITO layer by magnetron sputtering. The target used is a metal WMo planar target, the power supply is a DC power supply, and the power is 1-30KW. The process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com