Steel bar cutting device capable of automatically adjusting feeding speed

A feed speed, automatic adjustment technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of cutting blade damage, blade jamming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

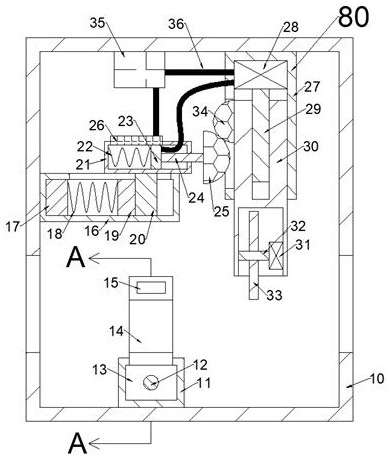

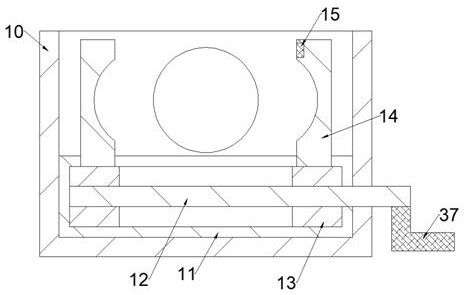

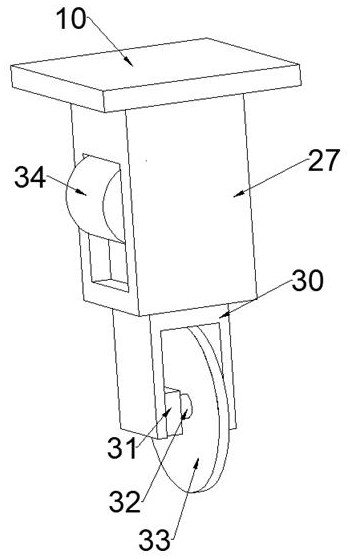

[0020] combined with Figure 1-3 The described steel bar cutting device that automatically adjusts the feed speed includes a body 10, a cutting mechanism 80 is arranged in the body 10, and the cutting mechanism 80 includes a cutting block 27 fixedly connected in the body 10, so The inside of the cutting block 27 is fixedly connected with a feed motor 28, the feed motor 28 controls a screw mandrel 29, and the screw mandrel 29 is threaded with a limiting block 30, and the limiting block 30 is slidably connected with the cutting block 27 A cutting motor 31 is fixedly connected inside the restriction block 30, and the cutting motor 31 controls a drive shaft 32, and a cutting blade 33 is fixedly connected to the drive shaft 32.

[0021] Beneficially, a moving block 34 is fixedly connected to the screw rod 29 .

[0022] Beneficially, the inside of the body 10 is fixedly connected with a fixed block 11, and the inside of the fixed block 11 is rotatably connected with a rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com