Non-curved mirror grinding tool

A curved mirror and tooling technology, which is applied to optical surface grinders, grinding workpiece supports, grinding drive devices, etc., can solve the problems of poor grinding quality and long grinding time of non-curved mirrors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

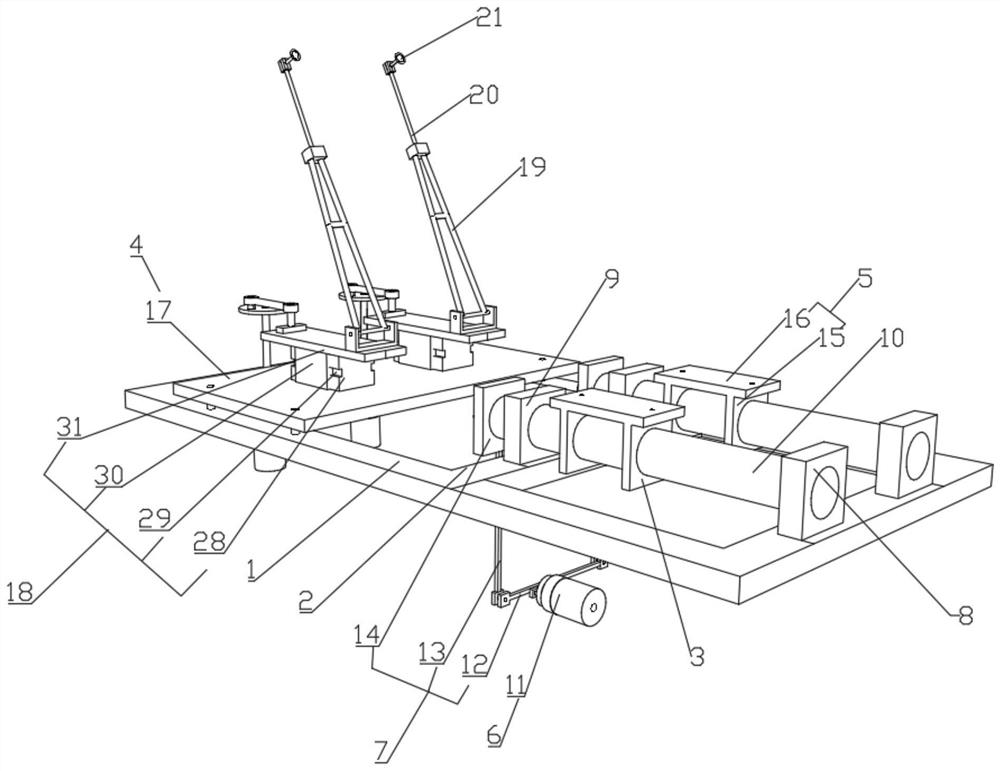

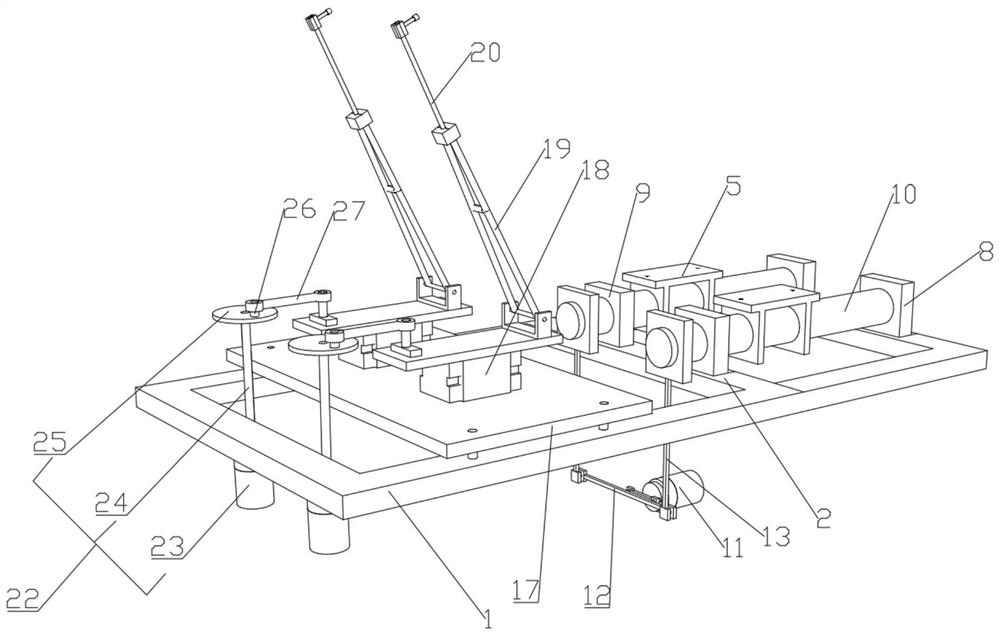

[0018] First of all, the original intention of the design of the present invention is explained. In recent years, with the development of optical products, the application of optical lenses has become more and more extensive. In the application of optical mirrors, it is necessary to grind the optical lenses. Non-curved mirror is a kind of optical lens. When grinding non-curved mirror, it needs to grind the non-curved mirror horizontally and vertically. Two steps, using two grinding machines, this way of grinding takes a long time, and the grinding quality of the non-curved mirror is poor. Therefore, the present invention designs a non-curved mirror grinding tool.

[0019] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 2 As shown, a non-curved mirror grinding tool includes a main mounting frame 1, on which an auxiliary connecting profile 2 is installed. In order to realize the grinding of non-curved mirrors, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com