Concrete reverse ridge accurate positioning mold and reverse ridge construction method

A precise positioning, concrete technology, applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, can solve problems such as form expansion, poor sealing, and changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

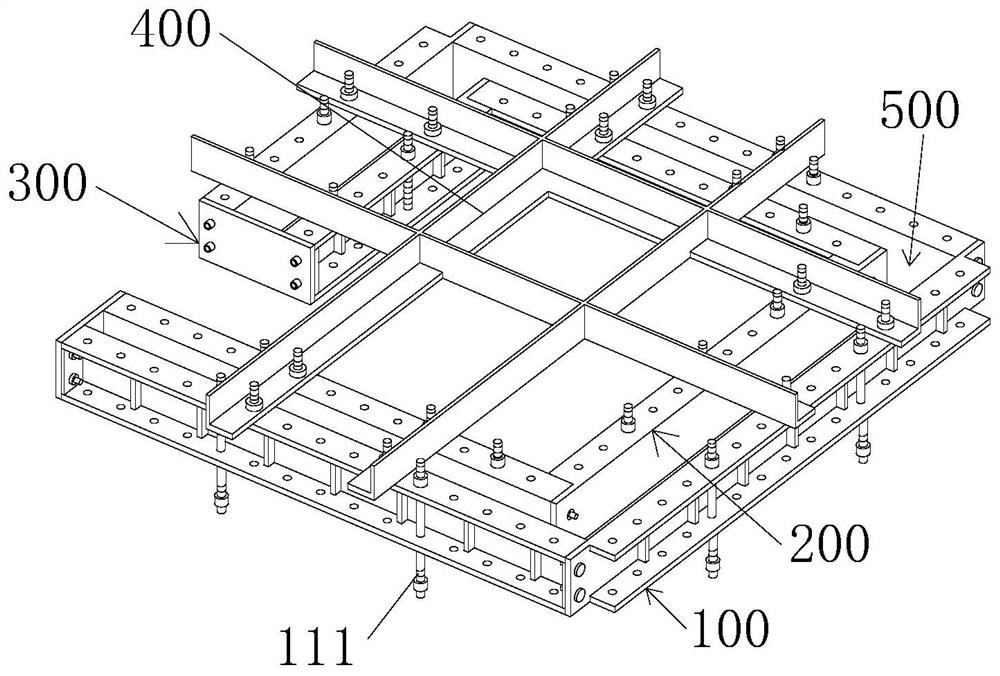

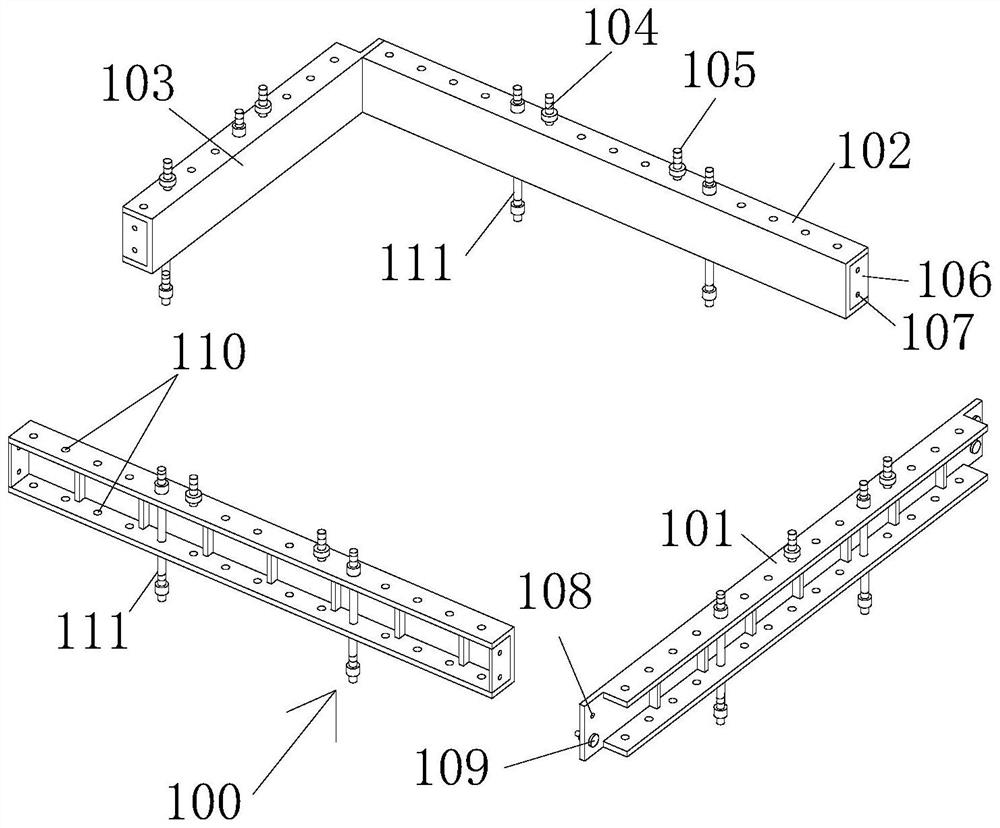

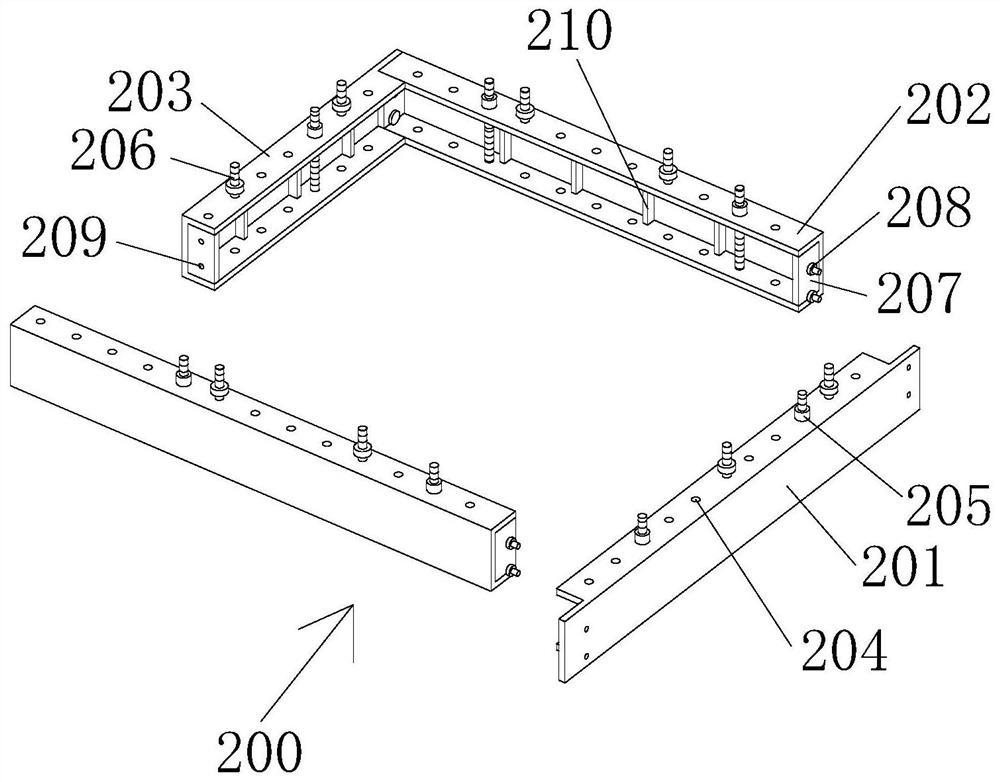

[0036] see Figure 1-5 As shown, the present invention is a concrete reverse sill precise positioning form, including an outer limiting formwork 100, an inner limiting formwork 200, a limiting sealing plate 300 and a fixing frame 400, the inner center of the outer limiting formwork 100 is provided with an inner limiting formwork 200, and an outer limiting formwork 200 is provided. The restriction formwork 100 cooperates with the inner restriction formwork 200 to restrict the inside and outside of the reverse sill that needs to be poured, and the two ends of one side of the rear side of the outer restriction formwork 100 and the inner restriction formwork 200 are fixed with a restriction sealing plate 300. The sealing plate 300 fixes the two contact points of the outer limiting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com