Pin header for corrugated board bonding strength experiment

A technology of bonding strength and corrugated cardboard, applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve the problems that the needle-shaped accessories cannot meet the experimental needs, and the single needle insertion method takes too long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

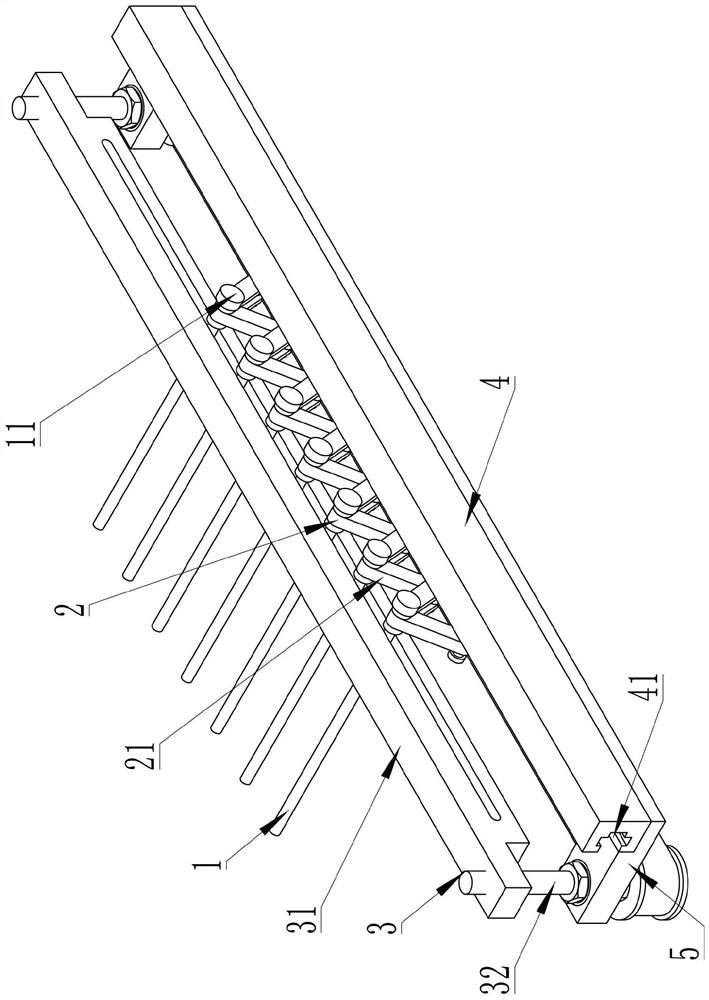

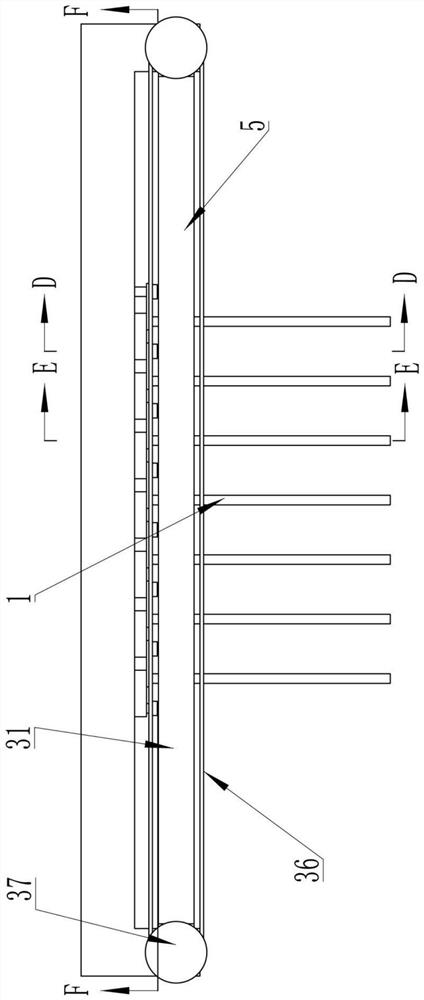

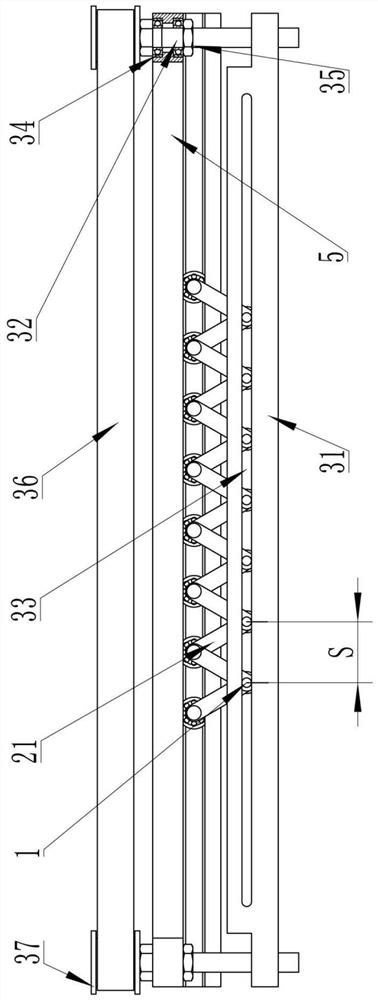

[0022] Combine below Figure 1 to Figure 6 Specific embodiments of the present invention will be described.

[0023] figure 1 and figure 2 The overall structural form of the layout of the pin header is shown. The experimental pin header includes: a non-closed chain 2 connected by fourteen chain links 21, seven pins 1 and eight sliding shafts 22 as a non-closed chain The hinge shafts of 2 are alternately interspersed between the chain links 21, and the hinge holes on the outside of the chain links 21 at both ends of the non-closed chain 2 are sliding shafts 22; wherein, the sliding shafts 22 can only move in the length direction of the chain 2 to adjust The distance S between each pin 1 and the number of pins 1 can be increased or decreased according to actual detection requirements. This embodiment is described with the most conventional distance between seven pins 1 .

[0024] image 3 The connection mode between the adjustment bolt and the pulley is illustrated. A horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com