Doubling method and doubling structure

A line structure and wire technology, which is applied in the field of paralleling method and paralleling structure, can solve the problems of heavy paralleling workload, uneven grounding effect and grounding quality, time-consuming and laborious failure rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a parallel method, and can be used to perform a parallel processing of a plurality of coaxial lines, with high parallel efficiency and low adverseity.

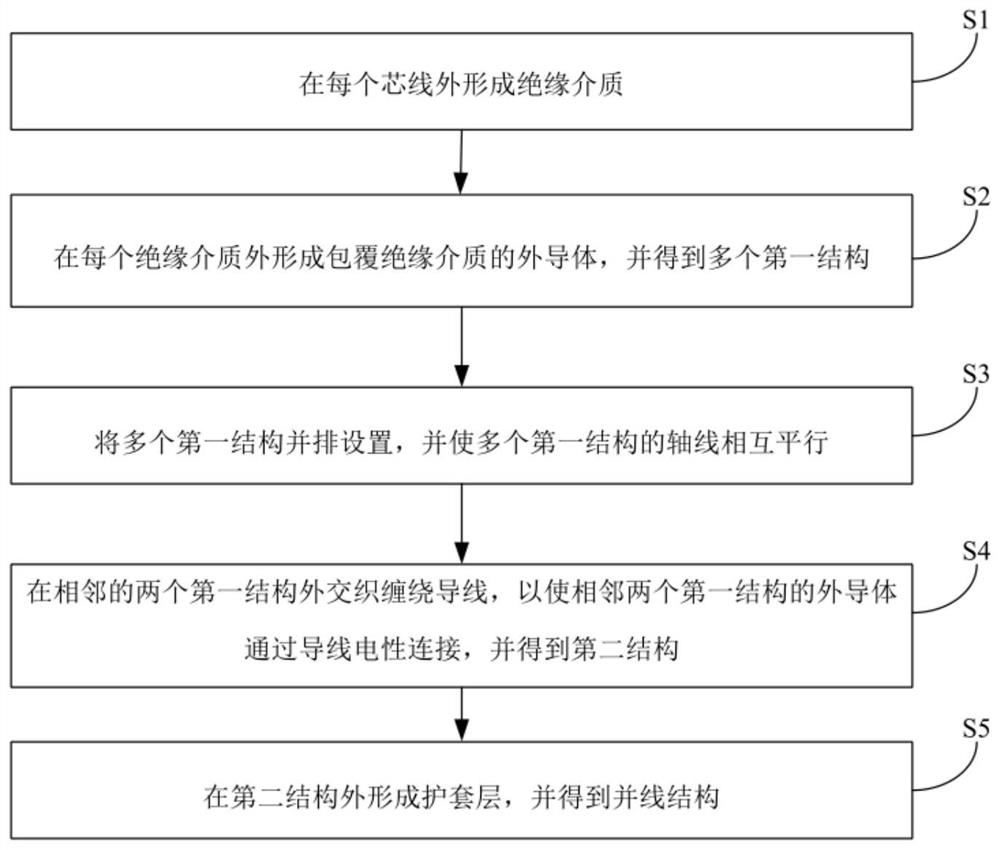

[0047] Such as figure 1 As shown, the parallel method includes the following steps:

[0048] S1, an insulating medium is formed outside each core wire.

[0049] Prior to step S1, it is possible to prepare a plurality of core wires 11, the lengths and lines of the plurality of core wires 11 are the same, and the core wire 11 is used to form the inner conductor 1 of the coaxial parallel structure. Copper is the main material of the core wire 11, the core wire 11 can be in the following form: annealing copper wire, annealing copper tube, copper-clad aluminum, silver-plated soft copper wire or tin wiring soft copper wire. The inner conductor 1 of usually a finer parallel structure is a copper wire or a copper-clad aluminum wire, while a coarse side-line structure uses a copper tube to reduce the weight ...

Embodiment 2

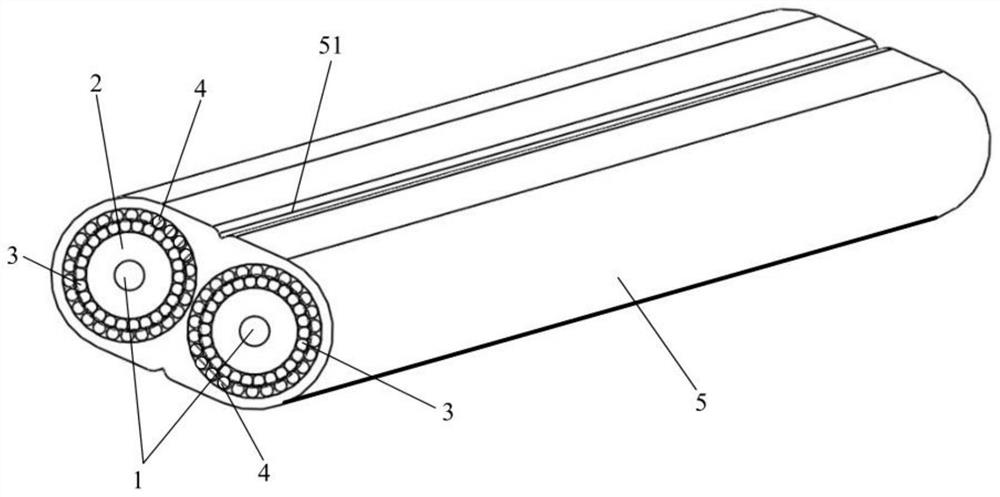

[0068] This embodiment provides a parallel structure, which is made by the above-described parallel method. Such as Figures 2 to 6 As shown, the parallel structure includes an inner conductor 1, an insulating medium 2, an outer conductor 3, a wire 4, and a sheath layer 5.

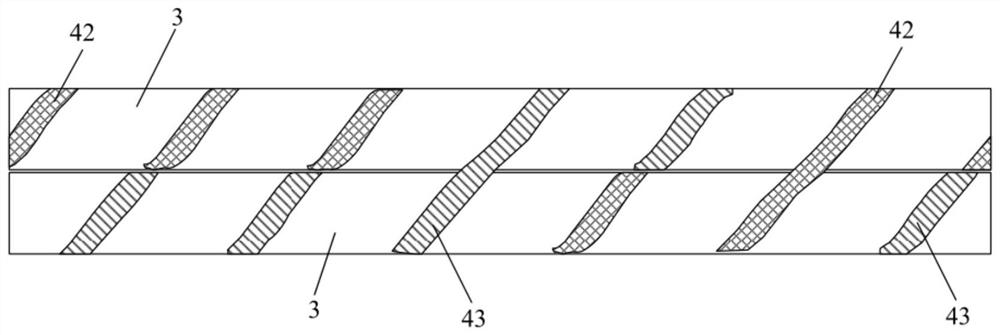

[0069] Wherein, the inner conductor 1 includes a plurality of side-by-side shaped core wires 11, and the axis of the plurality of core wires 11 is parallel to each other, i.e., a plurality of striped core wires 11 form an inner conductor 1. The insulative medium 2 is provided with a plurality of insulating media 2, and the plurality of core wires 11 corresponds, and each insulating medium 2 is covered with the corresponding core wire 11. The outer conductor 3 is provided with a plurality of outer conductor 3, and the plurality of insulating medium 2 corresponds, and each of the outer conductor 3 is disposed outside its corresponding insulating medium 2. Wire 4 is interleaved from adjacent two outer conductor 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com