Vertical cable stripping and shaping equipment

A cable and wire stripping technology, which is applied to equipment for dismantling/armouring cables, equipment for connecting/terminating cables, and installation of cables. It can solve the problems of time-consuming and labor-intensive cable terminals, many operating procedures, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

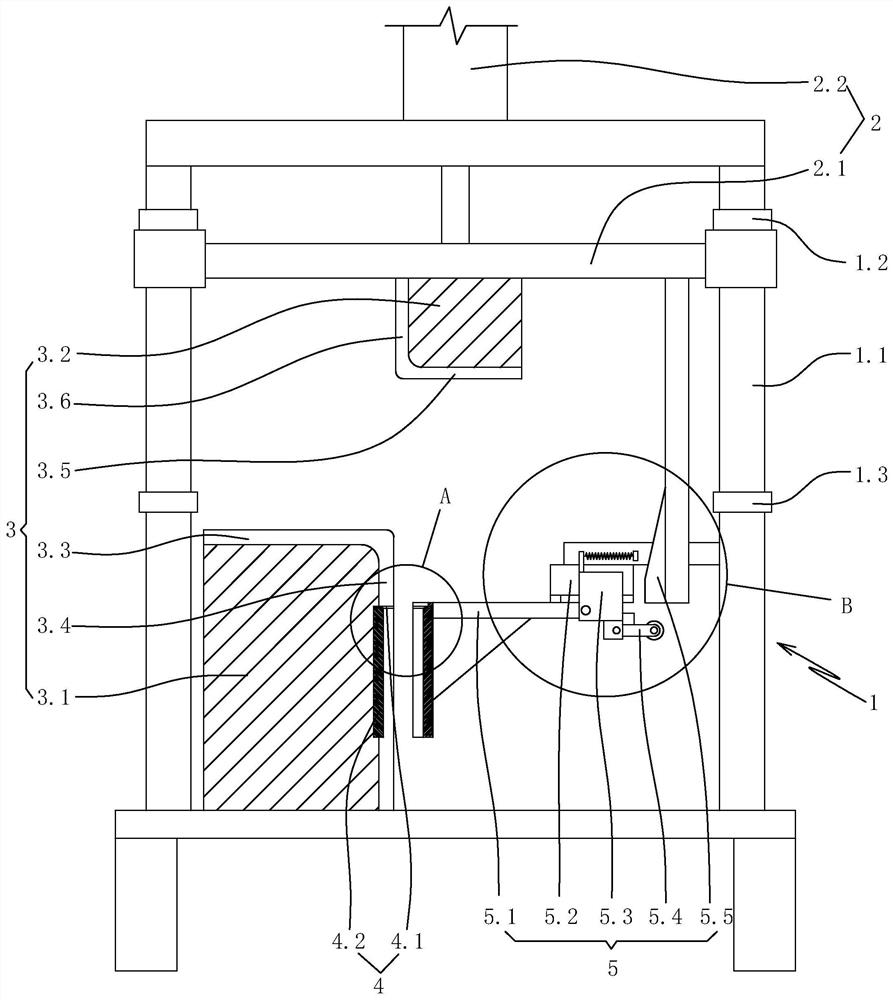

[0043] Specific embodiment one: as figure 1 As shown, a vertical cable stripping and shaping equipment includes a frame 1 , a lifting device 2 , a cable end bending device 3 , a rotary stripping knife driving device 5 and a stripping knife assembly 4 . The frame includes a base, a top frame and a column 1.1 arranged on the base. The top frame is fixed to the top of the column. The column is provided with an upper limit block 1.2 and a lower limit block 1.3.

[0044] The lifting device includes a lifting frame 2.1 lifting along the column and a lifting actuator 2.2 for lifting the lifting frame. The lifting frame is provided with a guide sleeve matched with the column, and the guide sleeve is located between the upper limit block and the lower limit block. The lifting actuator is a cylinder or an oil cylinder. The lifting actuator is fixed on the top frame.

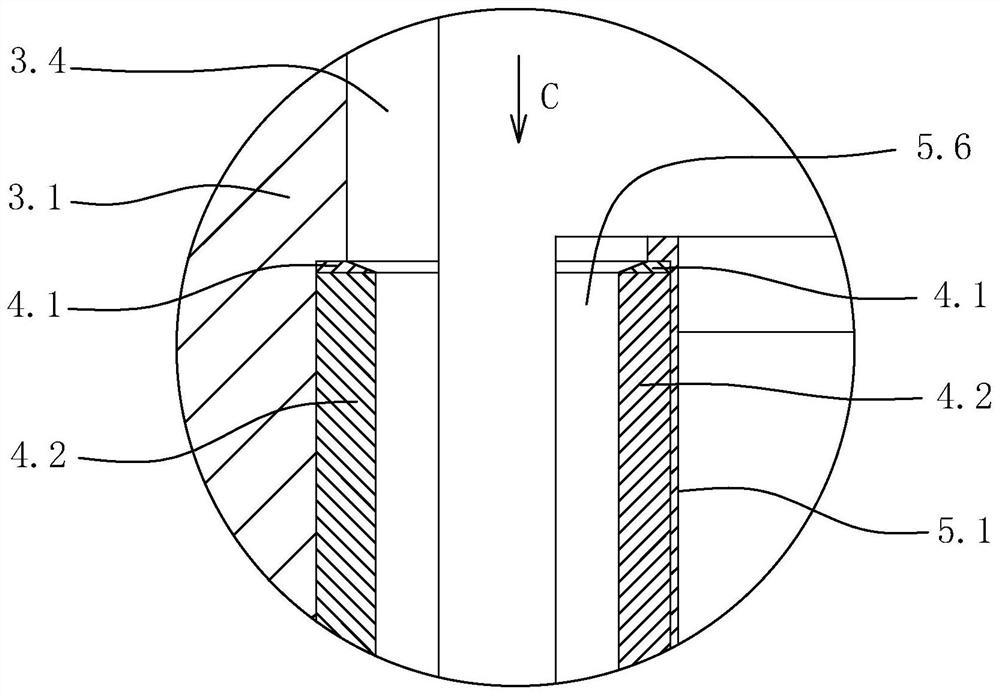

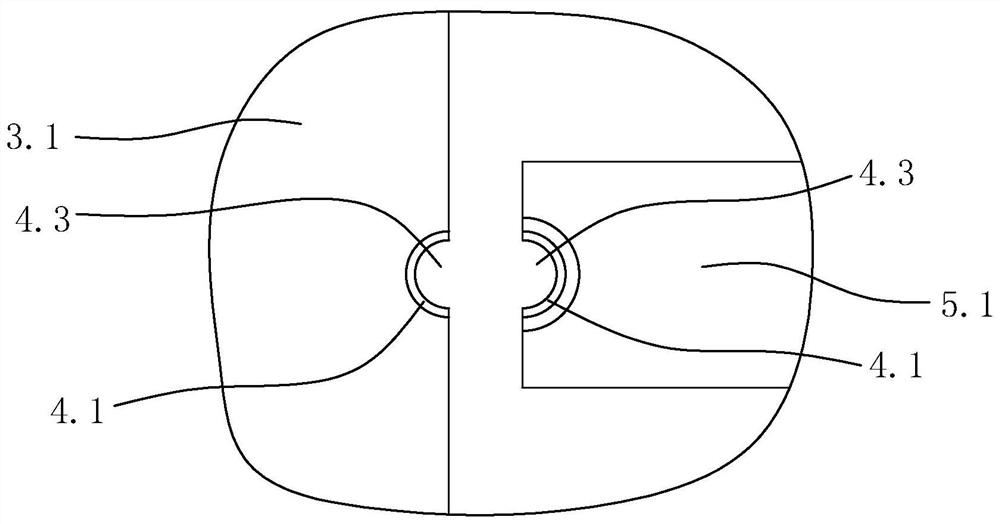

[0045] The cable end bending device 3 includes a lower module 3.1 fixed on the base and an upper module 3.2 fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com