Industrial robot fault diagnosis method and system based on infrared temperature measurement

A fault diagnosis system and industrial robot technology, applied in manipulators, manufacturing tools, etc., can solve problems such as low accuracy, lower detection efficiency, and inability to apply equipment temperature detection, and achieve the effect of improving accuracy and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

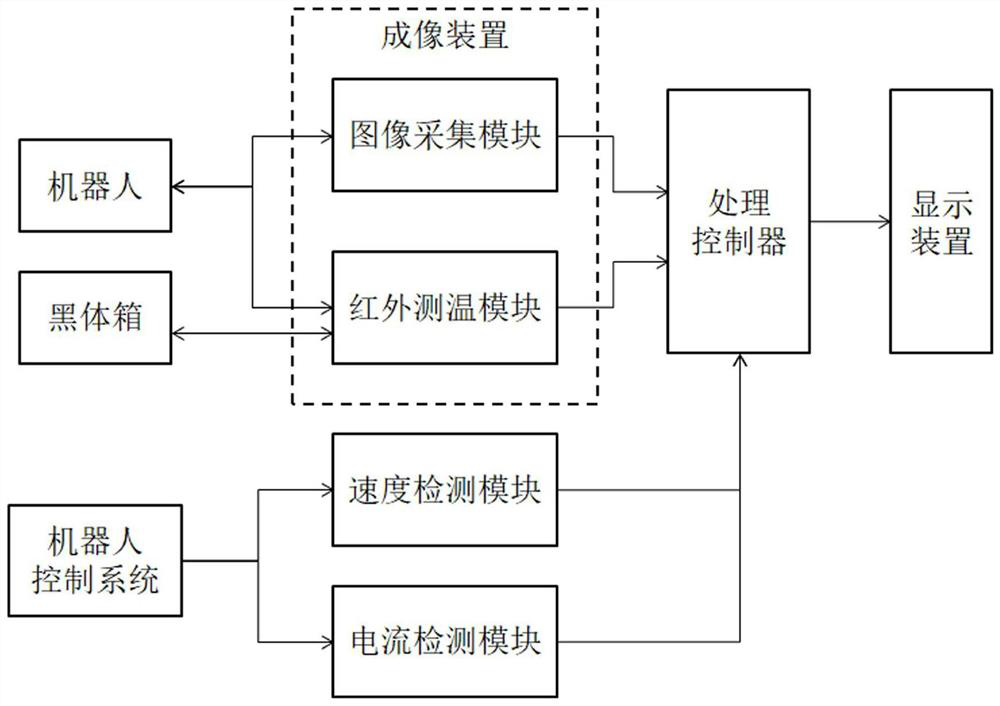

[0019] Embodiment 1, with reference to figure 1 , a kind of industrial robot fault diagnosis method based on infrared temperature measurement, it is characterized in that: comprise the following steps:

[0020] S01. Preparatory work: set the image acquisition module and the infrared temperature measurement module adjacent to each other and align them with the robot, and adjust the positions of the image acquisition module and the infrared temperature measurement module so that the field of view captured includes the entire operating range of the robot.

[0021] S02. Construction of the actual temperature model; first build the motor model for each axis motor of the robot, and then use the image acquisition module and the infrared temperature measurement module to simultaneously shoot the robot in real time to obtain visible light images and infrared images; The motor model of each axis determines the position of each axis motor in the visible light image, and then matches the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com