Code-scanning self-rotating tire vulcanizing machine tire mounting manipulator

A technology of tire vulcanization and manipulators, which is applied in the direction of manipulators, tires, chucks, etc., can solve the problems of low automation, low efficiency, and poor rotation accuracy, so as to reduce complex procedures and improve automation and intelligence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

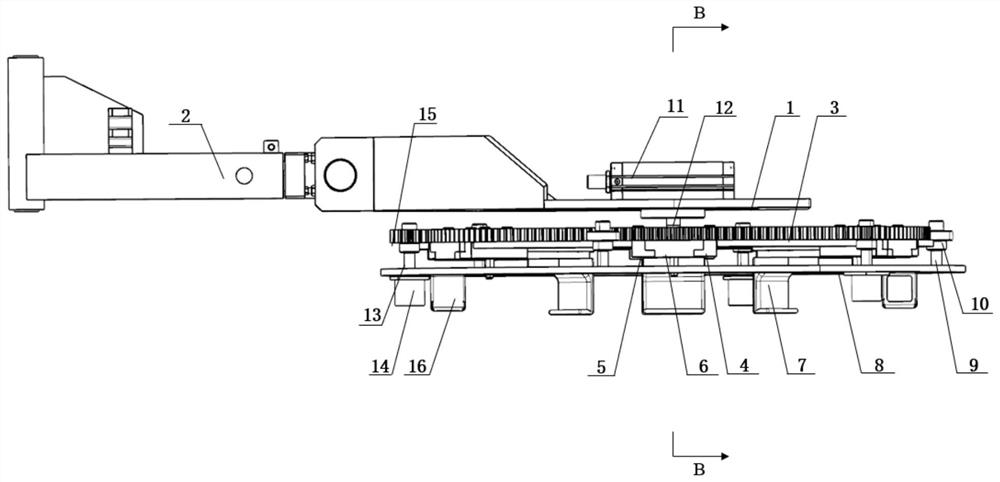

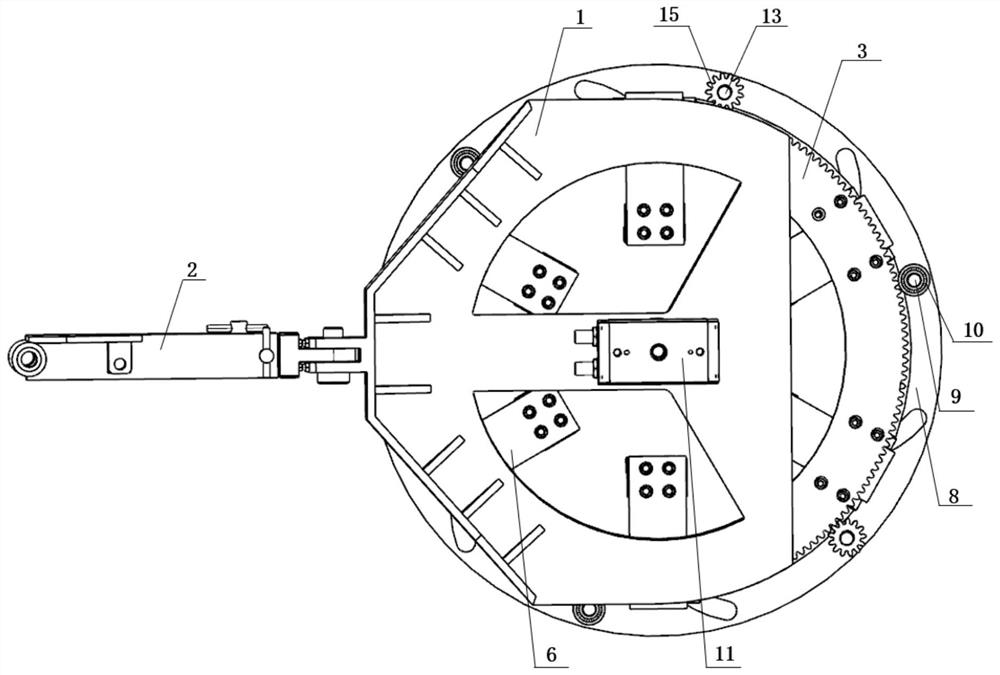

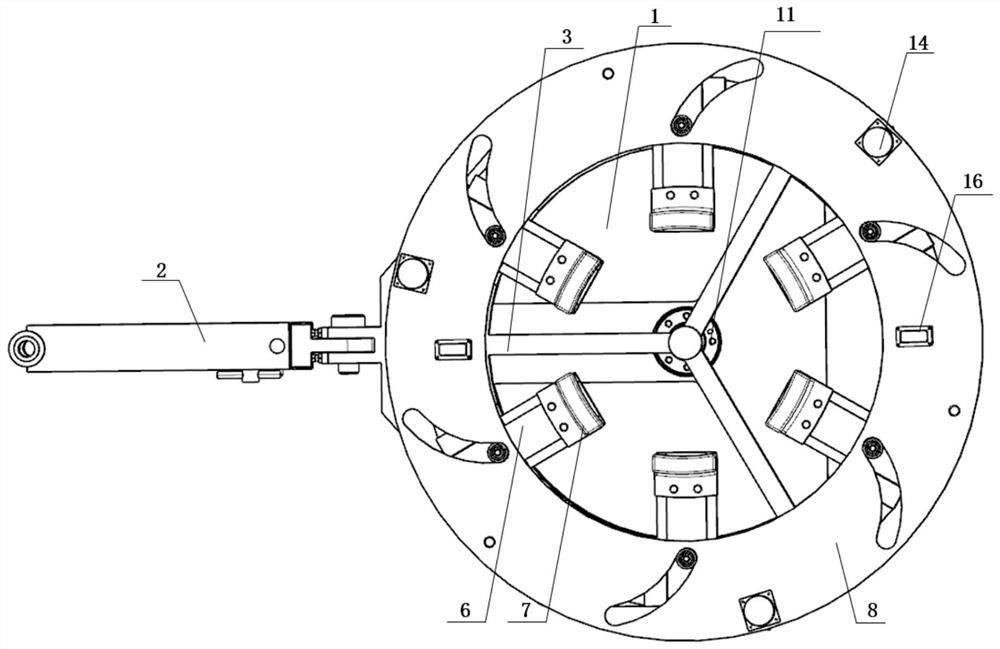

[0024] The invention provides a code-scanning self-rotating tire vulcanizing machine tire loading manipulator, which is mainly composed of an executing device and a driving device. Such as Figure 1-5 As shown, the actuator mainly includes a fixed plate 1, a connecting arm 2, an upper tooth plate 3, a right chute block 4, a left chute block 5, a slider 6, claw pieces 7, a lower turntable 8 and a code scanner 16 Composition; The driving device is composed of a rotary cylinder 11 and a gear motor 14. The fixed plate 1 is installed on the connecting arm 2 in the execution device of the self-rotating tire vulcanizer manipulator that can scan codes in the present invention, and the upper toothed plate 3 is installed under the fixed plate 1, and the upper toothed plate 3 has a double-layer structure. The upper layer of the upper toothed disc 3 is an annular ring gear, and the inner hole 3-2 at the center of the upper toothed disc 3 is connected with the connecting shaft 12. The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com