Nest-structure warm-keeping fabric and preparation process

A fabric and thermal insulation interlayer technology, applied in the field of fabrics, can solve problems such as heat dissipation, poor heat dissipation, and effective heat discharge, and achieve the effect of accelerating heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

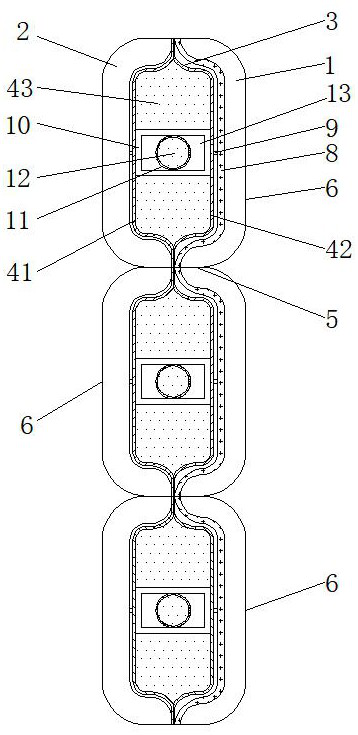

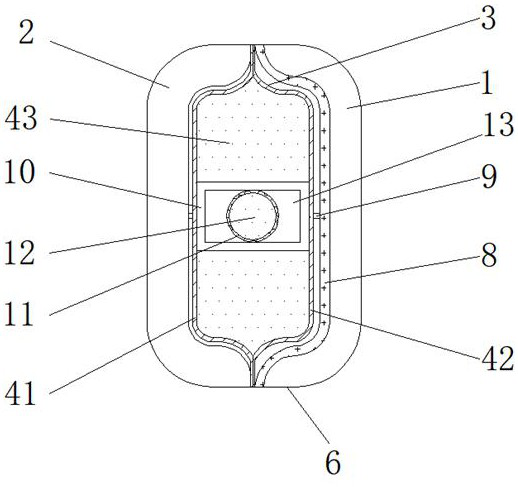

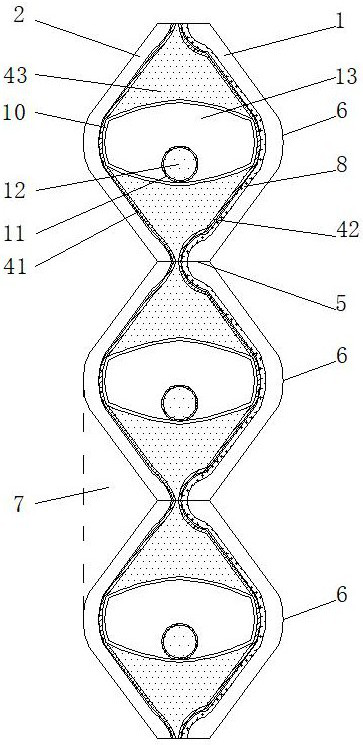

[0042] Such as Figure 1-6A nest structure thermal fabric shown, comprising an outer layer 1, an inner layer 2 and an insulating interlayer 3, an inner layer 2 is provided on the inner side of the outer layer 1, and an insulating interlayer 3 is provided between the inner layer 2 and the outer layer 1, The side of the outer layer 1 facing the inner layer 2 is glued with an insulating and breathable film 8, and both sides of the insulating interlayer 3 are respectively connected to the inner layer 2 and the outer layer 1 through connecting lines 29, and the insulating and breathable film 8 is a tpu waterproof and breathable film , through the thermal insulation and breathable membrane 8, it has the characteristics of high strength, good toughness, wear resistance, cold resistance, oil resistance, water resistance, aging resistance, and weather resistance. , anti-ultraviolet and energy release and many other excellent functions to enhance the thermal insulation and breathable ef...

Embodiment 2

[0052] The fabric structure in the present embodiment differs from Embodiment 1 in that: as Figure 7 As shown, a plurality of heat preservation units 6 in a square structure are formed between the inner layer 2 and the outer layer 1 through a connecting line 5;

[0053] The difference between the preparation process of the fabric in this embodiment and that of Example 1 is that in step 4, the thermal fabric is sewn into a plurality of heat preservation units 6 with a square structure through the connecting line 5, and all the heat preservation units 6 Form a complete and regular nest structure;

[0054] Others are identical with embodiment 1.

Embodiment 3

[0056] The fabric structure in this embodiment differs from that in Embodiment 1 in that: the first interlayer (41) and the second interlayer (42) are filled with thermal insulation material one (43), each of the spheres (11) The insides are all hollow, and each sphere (11) is filled with thermal insulation material two (12), and the thermal insulation material one (43) and thermal insulation material two (12) are white duck down.

[0057] The difference between the preparation process of the above-mentioned fabric and that of Example 1 is that the sphere 11 prefabricated in step 2 is hollow inside and the hollow is filled with white duck down;

[0058] In step 3, interlayer one (41) and interlayer two (42) are sewed on the inner layer (2) and outer layer (1) respectively through the connecting line two (9), and then the thermal insulation material one (43) Fill between interlayer one (41) and interlayer two (42).

[0059] The specific application process of the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com