High-elastic denim fabric and production process thereof

A denim fabric and production process technology, applied in the direction of fabric surface trimming, milling, spinning, etc., can solve the problems of increased production difficulty, scrapped jeans, gram weight, etc., to increase elastic resilience, reduce roughness, reduce Effect of usage amount of cotton

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

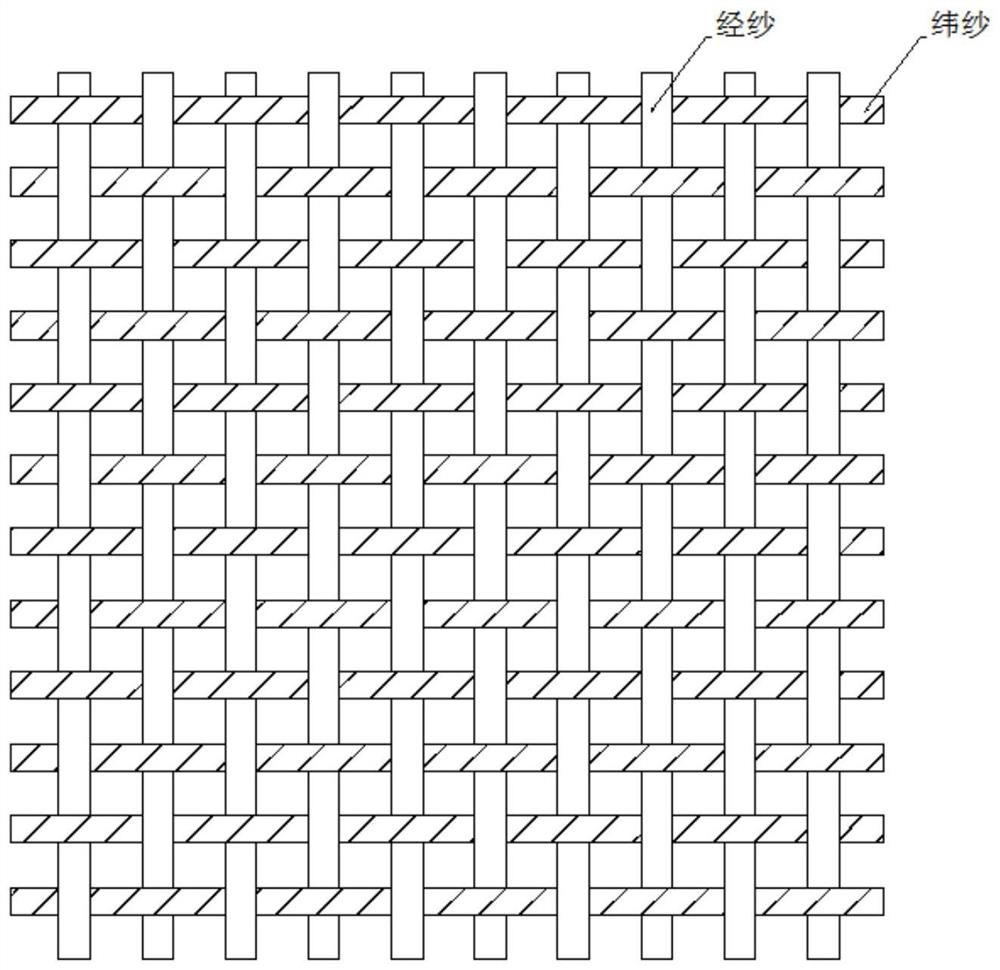

[0041] Referring to 1-2, in this embodiment, a high-elastic denim fabric is provided. The denim fabric is cross-woven by warp yarns and weft yarns, and contains the following raw materials by weight: 12%-14% cotton, 18-22% Tencel, 28-32% modal, 25-29% polyester, 6-10% viscose and 1-3% spandex;

[0042]Among them, the warp yarn is woven from 12S cotton tencel blended slub yarn and 10S cotton modal blended combed yarn, and the weft yarn is woven from 14S combed polyester viscose yarn, 75D polyester T400 and 70D spandex blend. The warp uses modal and tencel to replace most of the pure cotton in ordinary fabrics, leaving only part of the cotton to support the skinny feel of the entire pair of pants. Modal tencel will bring the smoothness and softness of the entire denim, while The yarn uses combed yarn, which replaces the open-air spinning and vortex spinning yarns of ordinary fabrics. The fabric surface has less hairiness, less impurities, and the fabric surface is cleaner. The ...

Embodiment 2

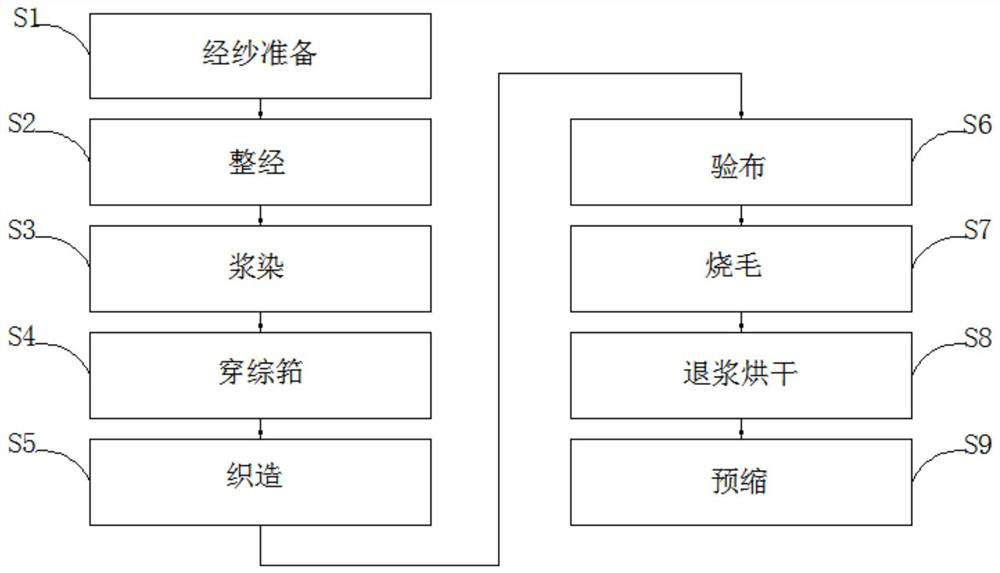

[0049] Referring to 3, in the present embodiment, a production process of a high-elastic denim fabric is provided, for producing the above-mentioned high-elastic denim fabric, comprising the following steps:

[0050] S1, warp yarn preparation: prepare the raw material warp yarn and weft yarn for producing high elastic denim fabric;

[0051] S2. Warping: The raw finished yarn is wound on the warp beam in parallel with the specified length and width through the warping machine. The technical parameters of the warping machine are designed as the force bar angle of 90 degrees, the upper tension ring is 12g, the middle 14g, and the lower 13g , Front 15g, middle 13g and rear 11g, the middle yarn tension is 13g, the edge yarn tension is 17g, the number of warps is 480, the speed is 350m / min, and the thread tension is 40g / piece;

[0052] S3, sizing and dyeing: the technological process is: process pre-treatment - dyeing and oxidation - washing and post-treatment - pre-baking - sizing ...

Embodiment 3

[0070] Referring to 3, in the present embodiment, a production process of a high-elastic denim fabric is provided, for producing the above-mentioned high-elastic denim fabric, comprising the following steps:

[0071] S1, warp yarn preparation: prepare the raw material warp yarn and weft yarn for producing high elastic denim fabric;

[0072] S2. Warping: The raw finished yarn is wound on the warp beam in parallel with the specified length and width through the warping machine. The technical parameters of the warping machine are designed as the force bar angle of 90 degrees, the upper tension ring is 12g, the middle 14g, and the lower 13g , Front 15g, middle 13g and rear 11g, the middle yarn tension is 13g, the edge yarn tension is 17g, the number of warps is 480, the speed is 350m / min, and the thread tension is 40g / piece;

[0073] S3, sizing and dyeing: the technological process is: process pre-treatment - dyeing and oxidation - washing and post-treatment - pre-baking - sizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com