A kind of visible light photocatalytic composite light-transmitting concrete and its preparation method and application

A light-transmitting concrete and visible light technology, applied in the field of concrete, can solve the problems of low purification efficiency of pollutants, low efficiency of solar energy utilization, unclear reaction mechanism, etc., and achieve good light transmission performance, good mechanical performance, decorative and practical functions The effect of increasing the catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] This embodiment 1 provides diatomaceous earth loading g-C 3 N 4 The preparation method of photocatalyst is as follows:

[0070] 1. Diatomite pretreatment: put 1.0g of diatomite into a plastic beaker, add 20ml of 2.0mol / L NaOH aqueous solution and diatomite to mix, and stir under magnetic. After reacting at room temperature for 12 hours, the samples were collected, washed to pH 7.0, dried at 80°C overnight, and ground into diatomite powder;

[0071]2. Diatomaceous earth loading g-C 3 N4 photocatalyst (diatomaceous earth@g-C 3 N 4 )Synthesis:

[0072] First, take 0.01g, 0.02g, 0.04g, 0.10g or 0.20g of diatomite powder in step 1 and disperse them in 30mL of methanol at room temperature for 30min with continuous ultrasound to obtain a well-dispersed diatomite suspension. Add 4.0g melamine to the soil suspension, stir at 25°C for 4 hours, then dry at 70°C for 6 hours, and calcinate the dried mixture in a muffle furnace at 550°C for 4 hours to obtain diatomite-loaded g-...

Embodiment 2

[0075] The optical fiber wrapped with protective layer used in concrete is prepared as follows:

[0076] Use UV glue and the diatomaceous earth load g-C that embodiment 1 prepares 3 The mixture of N4 photocatalysts is coated on the surface of the optical fiber to form a protective layer. The optical fiber (optical fiber) adopts polymethyl methacrylate PMMA plastic optical fiber wire with a diameter of 1mm to 2mm.

[0077] The purpose of optical fiber coating: to protect the surface of the optical fiber fiber from damage, improve its mechanical strength, and reduce attenuation; when it is combined with concrete, it can ensure better light-guiding and energy-transmitting performance, and to a certain extent, it can enhance the light-transmitting concrete Mechanical properties; In addition, a small amount of diatomaceous earth@g-C is added to the UV glue coated with optical fiber 3 N 4 The photocatalyst enables the optical fiber and the photocatalytic material to react quickly...

Embodiment 3

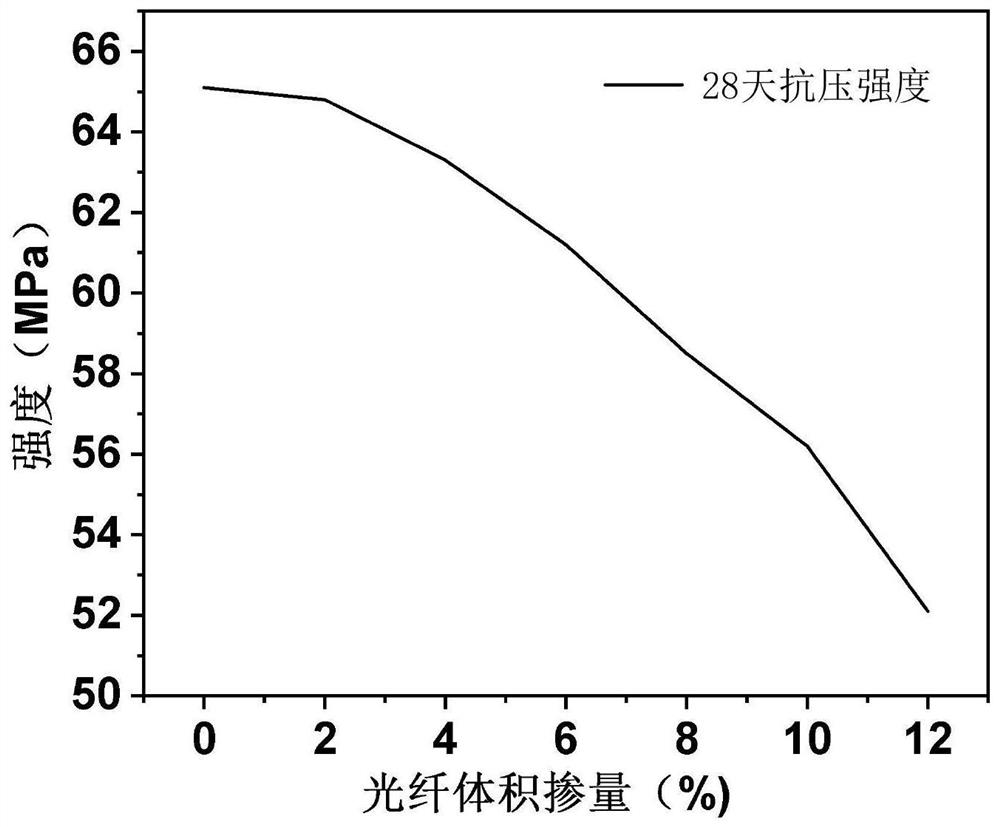

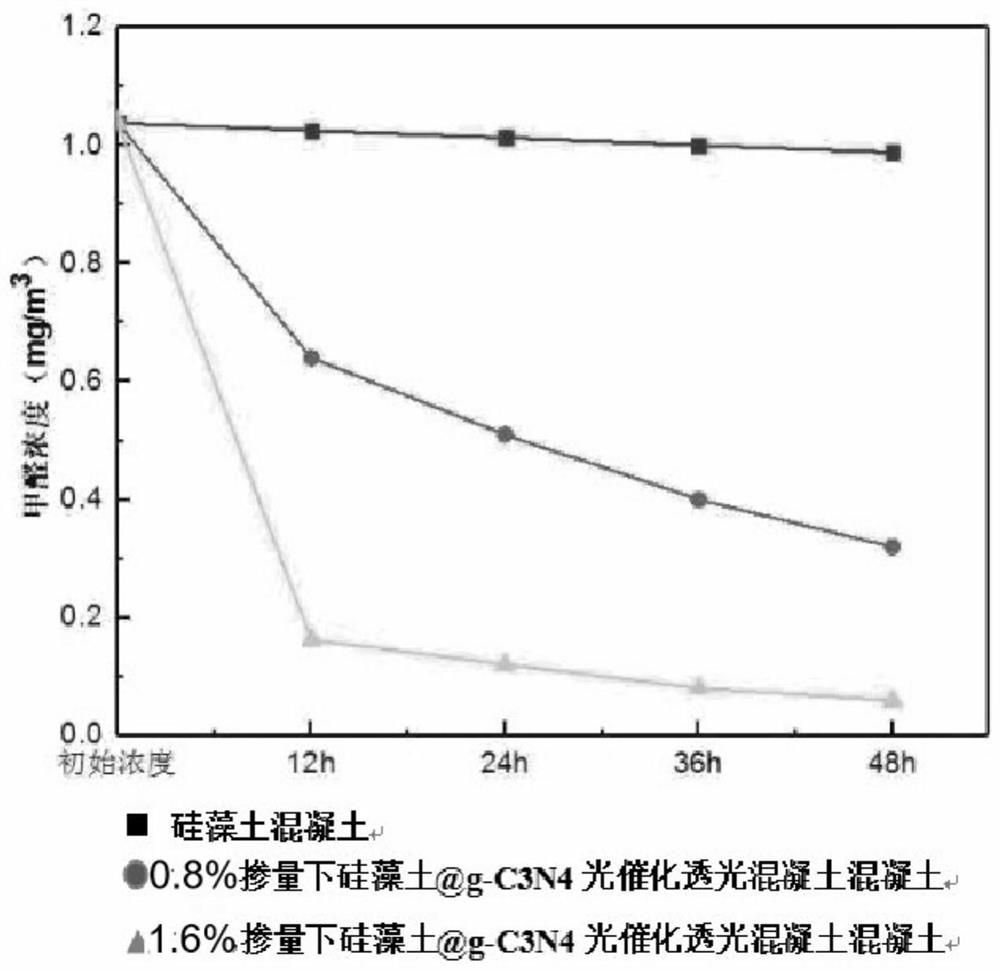

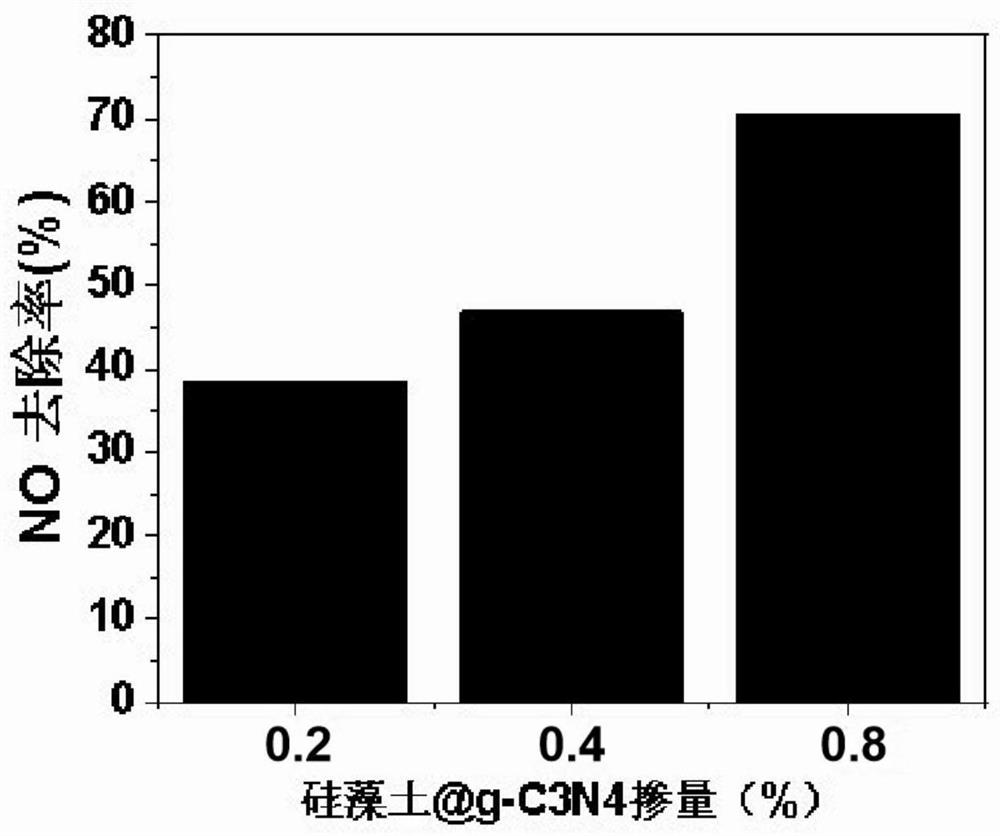

[0099] This embodiment 3 provides a visible light photocatalytic composite light-transmitting concrete. The concrete contains several bundles of optical fibers. The outer surface of the optical fibers is wrapped with a protective layer. The protective layer contains a visible light photocatalyst. The concrete is arranged in an array, the protective layer is a mixture of light-transmitting glue and a visible light photocatalyst, and the concrete contains cement and a visible light photocatalyst dispersed in the cement.

[0100] Raw material: the diatomaceous earth @g-C that embodiment 1 obtains 3 N 4 Photocatalyst, several bundles of optical fiber coated with a protective layer obtained in Example 2, cement, polycarboxylate water reducer, water, fly ash and regenerated coarse aggregate. The best mix ratio in the cement base is: water-cement ratio (referring to the ratio of water consumption per cubic meter of concrete to all cementitious material consumption): 0.35, aggregate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap