Intelligent material control method in aluminum electrolysis production process

A production process, aluminum electrolysis technology, applied in the field of intelligent material control in the aluminum electrolysis production process, can solve the problems of increased material accumulation at the cutting point, material accumulation phenomenon, and reduced demand for alumina, so as to improve the accuracy of material control Sexuality, reduce labor intensity, and determine the effect of accurate conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

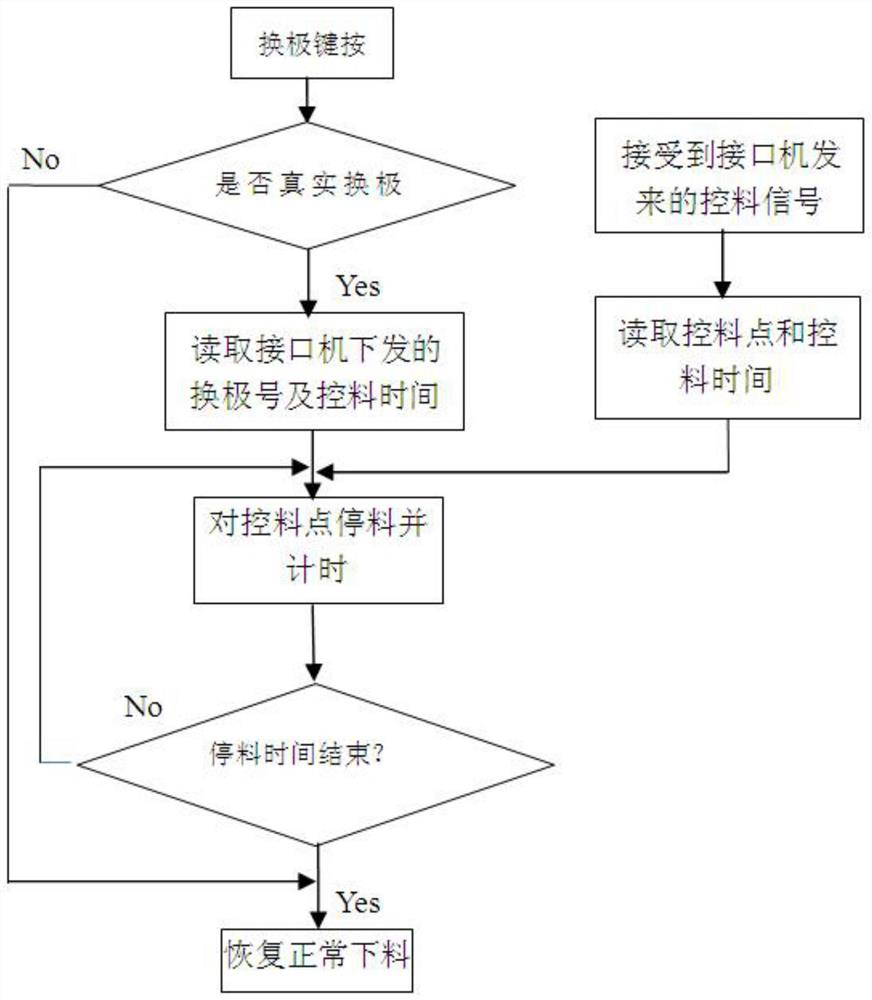

[0009] Embodiment 1: as figure 1 As shown, an intelligent material control method in the production process of aluminum electrolysis, the method includes material control after pole change and material control without pole change. The method of material control after pole change is: the interface machine automatically Update the pole change number and automatically send it to the tank control machine. When the tank control machine detects that the pole change key is pressed, it enters the pole change control, detects the voltage change of the electrolyzer, and performs pole change timing at the same time. If the voltage of the electrolyzer is detected If the change meets the real pole changing conditions or the pole changing duration exceeds the set time (such as 20 minutes), it is considered to be a real pole changing. Then after the pole changing is over, the tank control machine will automatically adjust the new anode according to the pole changing number issued by the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com