Prestressed system fabricated underground structure and construction method thereof

An underground structure and prefabricated technology, used in underwater structures, infrastructure engineering, structural elements, etc., can solve the problem that the bolt connection cannot effectively transmit the bending moment, the number of sleeve connection sleeves is large, and the sleeve pre-embedding accuracy requirements High-level problems, to solve the problem of labor shortage, significant social and economic benefits, and reduce on-site labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

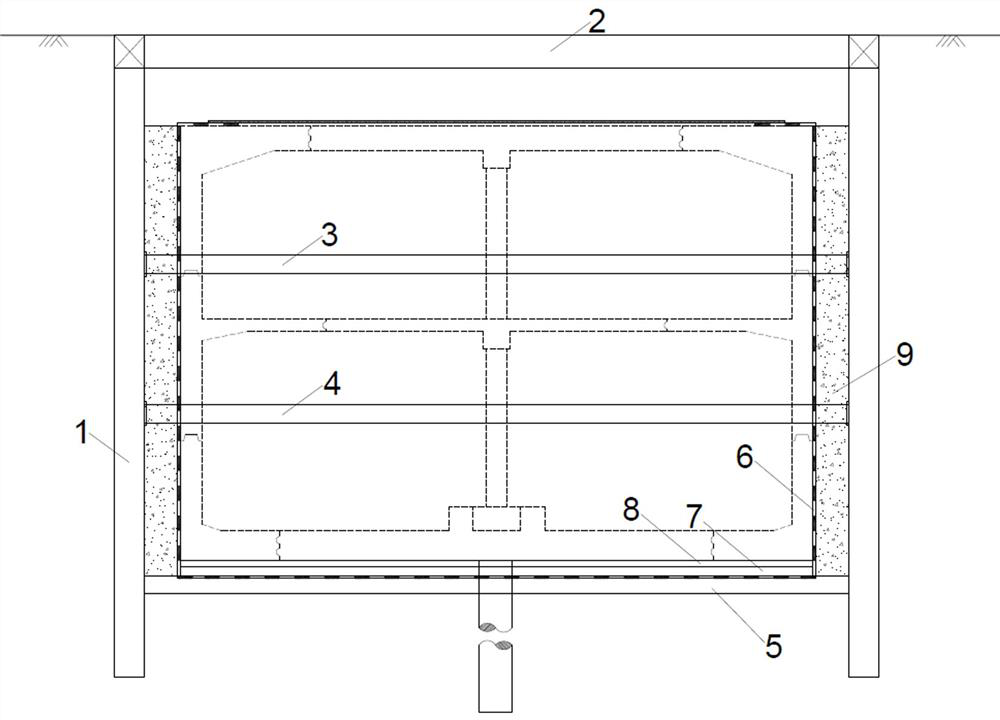

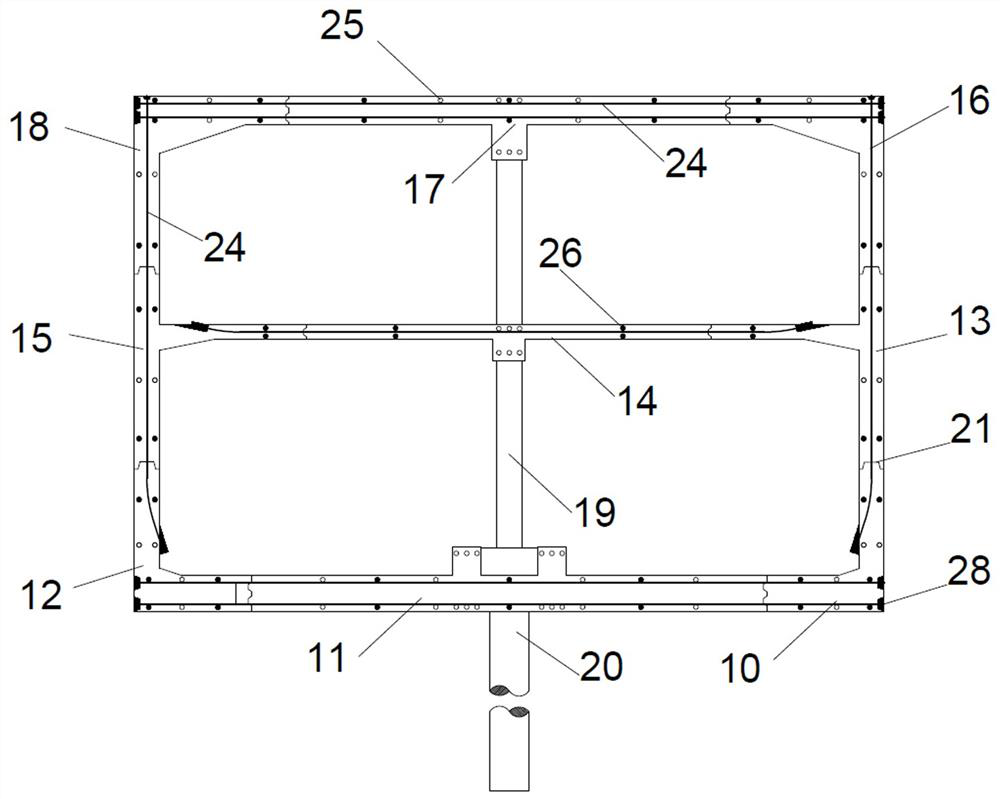

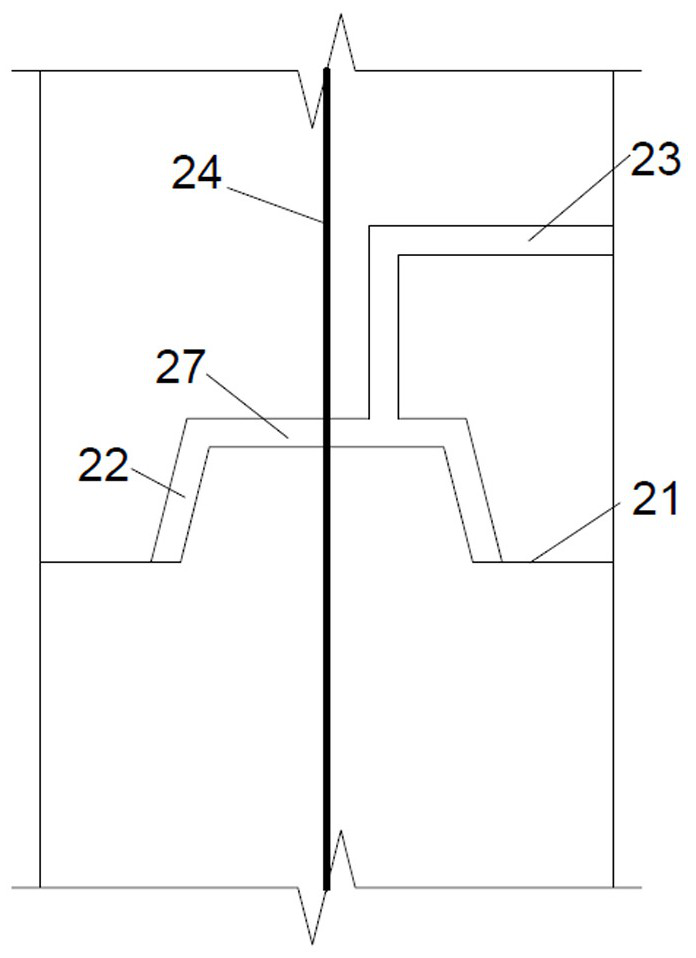

[0059] An assembled underground structure of a prestressed system includes an underground enclosure structure and an assembled underground main structure. see figure 1 As shown, the underground enclosure structure includes the underground diaphragm wall 1 on both sides of the foundation pit bottom, the first concrete support 2 supported on the top of the underground diaphragm wall 1 on both sides, and the second concrete support 2 supported on the middle part of the underground diaphragm wall 1 on both sides. The steel support 3 and the third steel support 4 supported on the lower part of the underground diaphragm wall 1 on both sides, wherein the first concrete support 2, the second steel support 3 and the third steel support 4 are temporary support members, the The prefabricated underground main structure is installed and constructed in the underground diaphragm walls 1 on both sides with the support of temporary supporting components. After the construction of the prefabric...

Embodiment 2

[0065] A construction method for an assembled underground structure of a prestressed system comprises the following construction steps.

[0066] S1, construction of underground enclosure structure, using the open cut method to construct the foundation pit, the enclosure structure adopts an underground diaphragm wall 1 with a thickness of 800mm, and the wall width is 6.75m; the first internal support adopts the first concrete support 2 of 900×1000mm, The support spacing is 9m; the second and third lines adopt φ800, t=16mm second steel support 3 and third steel support 4, and the steel support spacing is 4.5m and 2.25m intervals. The foundation pit is excavated and supported as it is excavated layer by layer to the bottom of the foundation pit, and the concrete cushion layer 5, waterproof layer 6, protective layer 7, and elevation fine-tuning layer 8 are constructed.

[0067] S2, assembling the assembled underground main structure in the circumferential direction to form the ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com