A modular prefabricated integrated building construction system and its construction method

A construction method and modular technology, applied in the direction of building structure, building, building type, etc., can solve the problems of low utilization rate and transportation efficiency of building materials and components, long on-site construction and installation time, and low overall assembly rate, etc. The effect of high assembly rate, small space occupation, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0096] The present invention will be further described below in conjunction with drawings and embodiments.

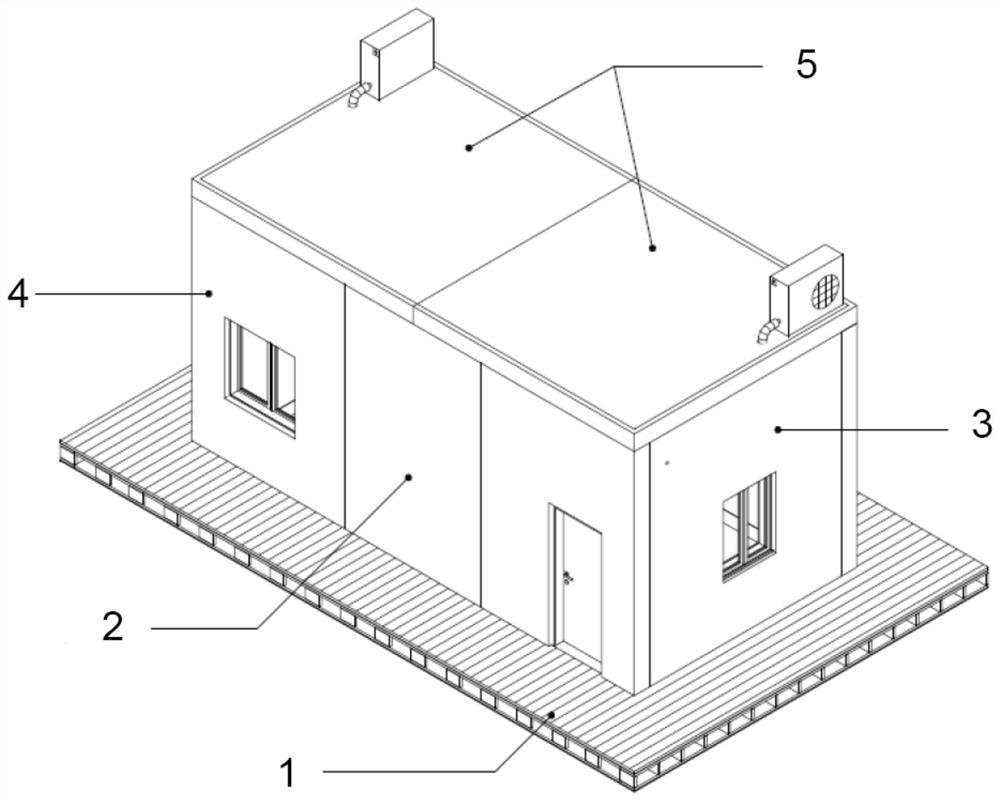

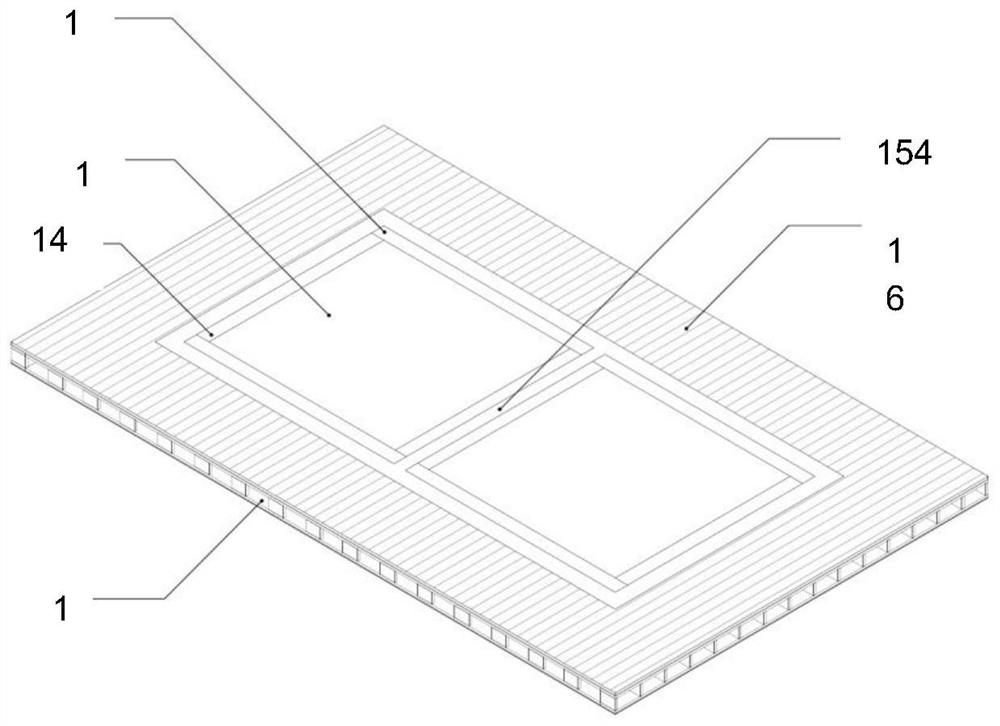

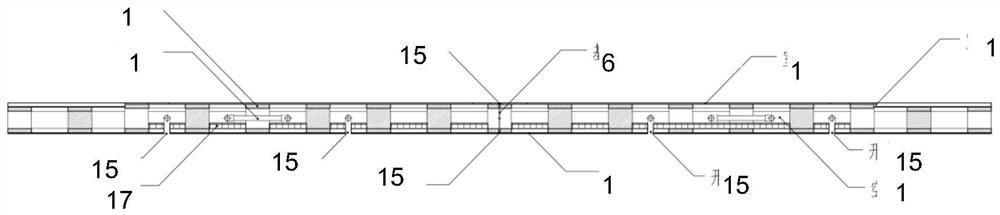

[0097] Such as figure 1 As shown, a modular prefabricated integrated building construction system includes a building base part 1, a side exterior wall part 3, a corner exterior wall part 4, a central exterior wall part 2, an interior wall part 6 and a roof part 5. The above components are connected by wooden dovetail joints to form a whole house. Each of the above-mentioned components integrates the building structure, thermal insulation, decorative surface materials and external protection structure, and at the same time integrates and pre-assembles the electromechanical equipment and pipeline systems used in the building.

[0098] Such as Figure 8 , 9 As shown, the wooden dovetail includes a head tenon 281 and a tail tenon 282 . The cross section of the head tenon 281 is isosceles trapezoid; and the length D2 of the lower bottom of the isosceles trapezoid in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com