Method and system for detecting wafer distribution range and storage medium

A distribution range and wafer technology, applied in the field of wafer bonding, can solve the problems of wafer waste, high time cost, etc., achieve the effect of reducing the search area and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

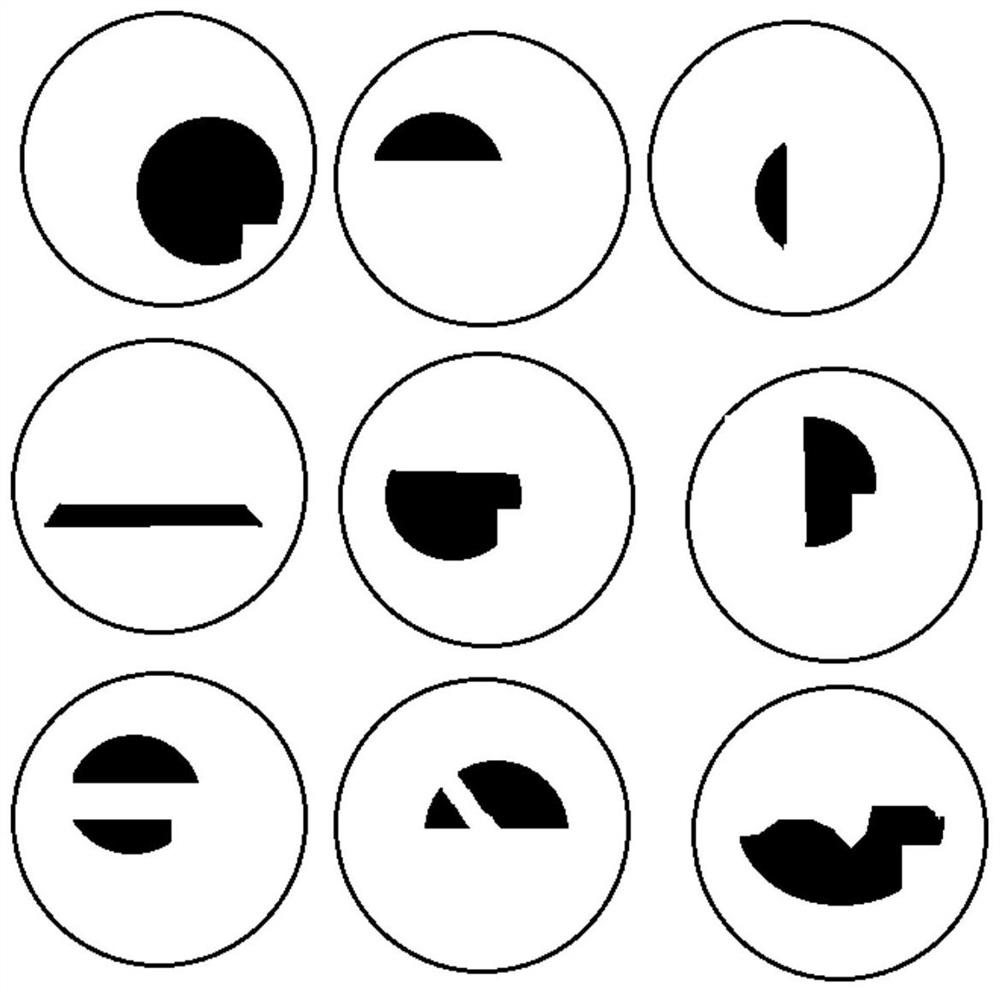

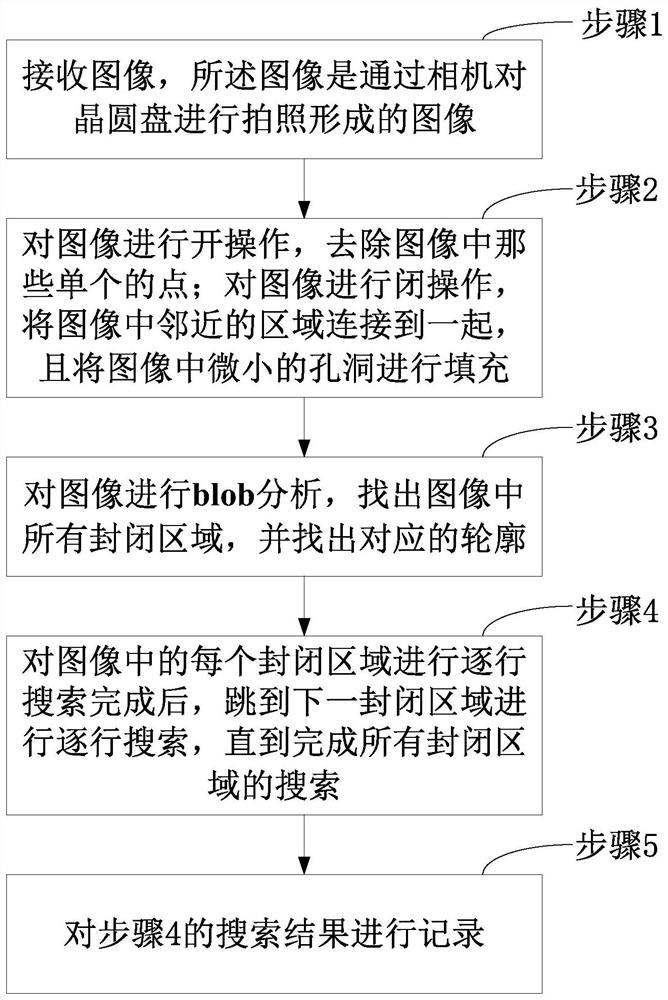

[0027] First of all, let's take a look at the wafer distribution diagram, such as figure 1 As shown, the distribution range of wafers from upstream is various, especially the wafers left after trial production or production of die bonders from multiple manufacturers. figure 1 The circle in represents the inner frame of the wafer disk, and it can be seen that the wafer distribution is uncertain.

[0028] In the present invention, a camera is added, and the camera is preferably a global camera. Specifically, a global camera is added at an appropriate position of the device, and after the orientation of the wafer is correct, a photo is taken of the entire wafer. In order to reduce distortion and take into account the installation position, a medium focal length or a slightly longer lens can be used. Generally, the distortion can reach less than 0.5%. The calibration template produced by the camera manufacturer can also be used to calibrate the image, and relevant information can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com