Design method of hot-rolled wide strip steel production process

A technology of production process and design method, which is applied in the field of iron and steel metallurgy, can solve the problems of time-consuming, labor-intensive, and complicated work for the daily maintenance of product quality plans, and achieve short product production cycles, reduced production costs, and fine calculation processes and accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

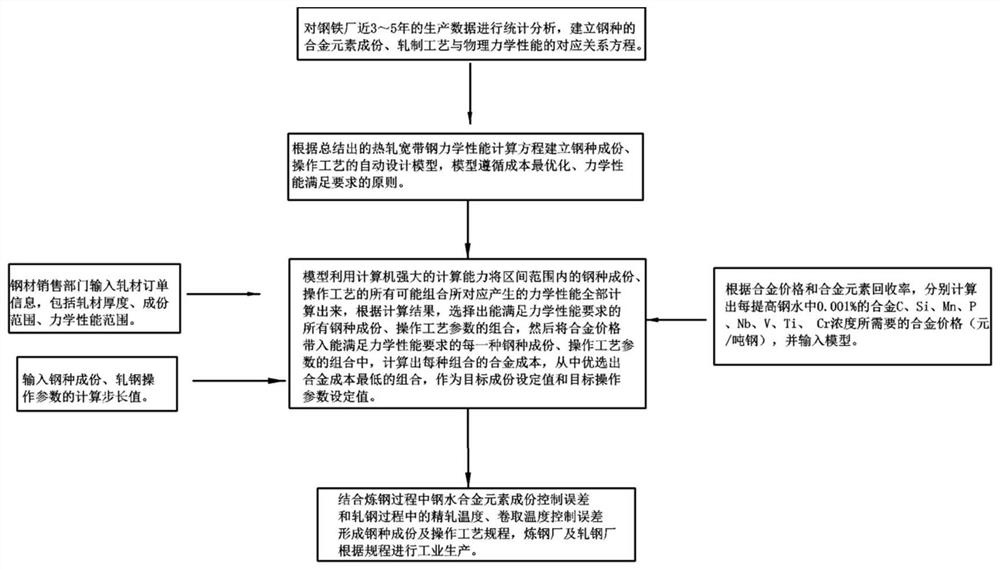

[0092] Such as figure 1 As shown, the annual output of a hot-rolled coil production line in a steel plant is about 2.3 million tons. The equipment and process parameters of the steel plant are: nitrogen content in molten steel: 30-60ppm, casting slab thickness: 175mm; casting slab heating in the heating furnace Time: 100 ~ 150min; heating furnace exit temperature: 1200 ~ 1260 ℃; rough rolling pass: 5 passes; intermediate billet thickness: 32 ~ 38mm; finish rolling pass: 5 ~ 7 passes; finish rolling Inlet temperature: 1000~1080℃; effective length of cooling line after rolling: 62m.

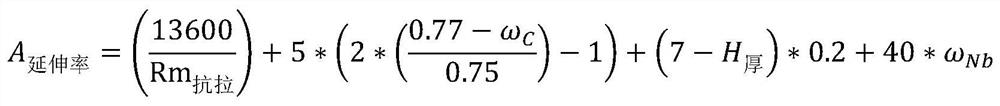

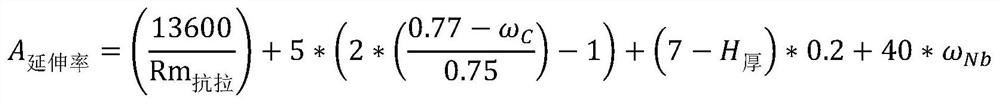

[0093] By counting the production data of about 60,000 batches of rolled materials in the past three years of the hot-rolled coil line, the corresponding relational equations of the average value of the steel grades, the rolling process and the average value of physical and mechanical properties are obtained, such as the invention of the present invention in the content The formula includes the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com