Cylindrical microwave applicator

An applicator, cylindrical technology, used in the field of high-efficiency cylindrical microwave applicators, which can solve problems such as unevenness and poor heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

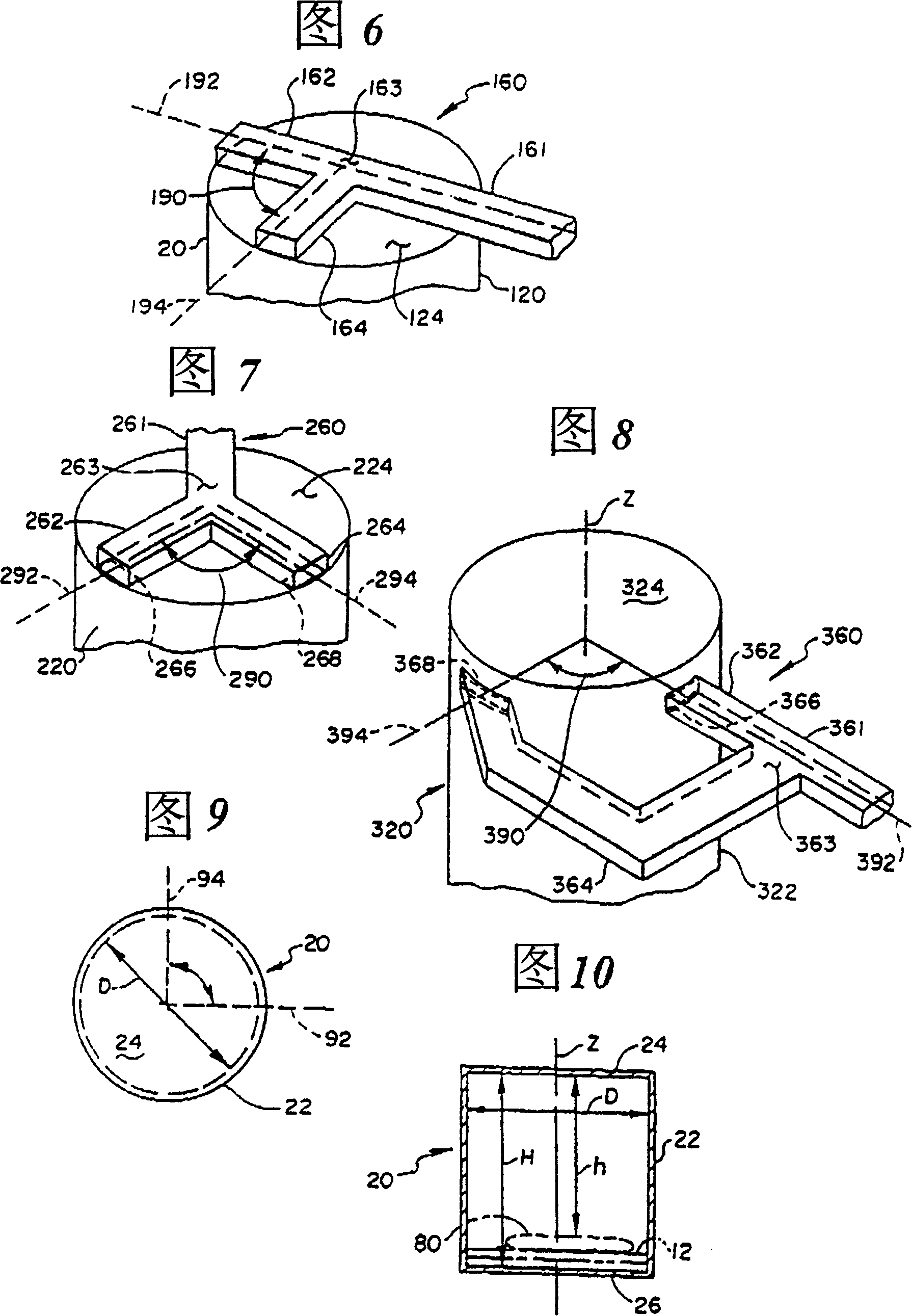

[0065] The present invention is a microwave applicator that efficiently and uniformly heats a load by eliminating hot and cold spots. Additionally, the present applicator uses cavity modes to eliminate edge overheating, reduce microwave energy leakage, and operate efficiently.

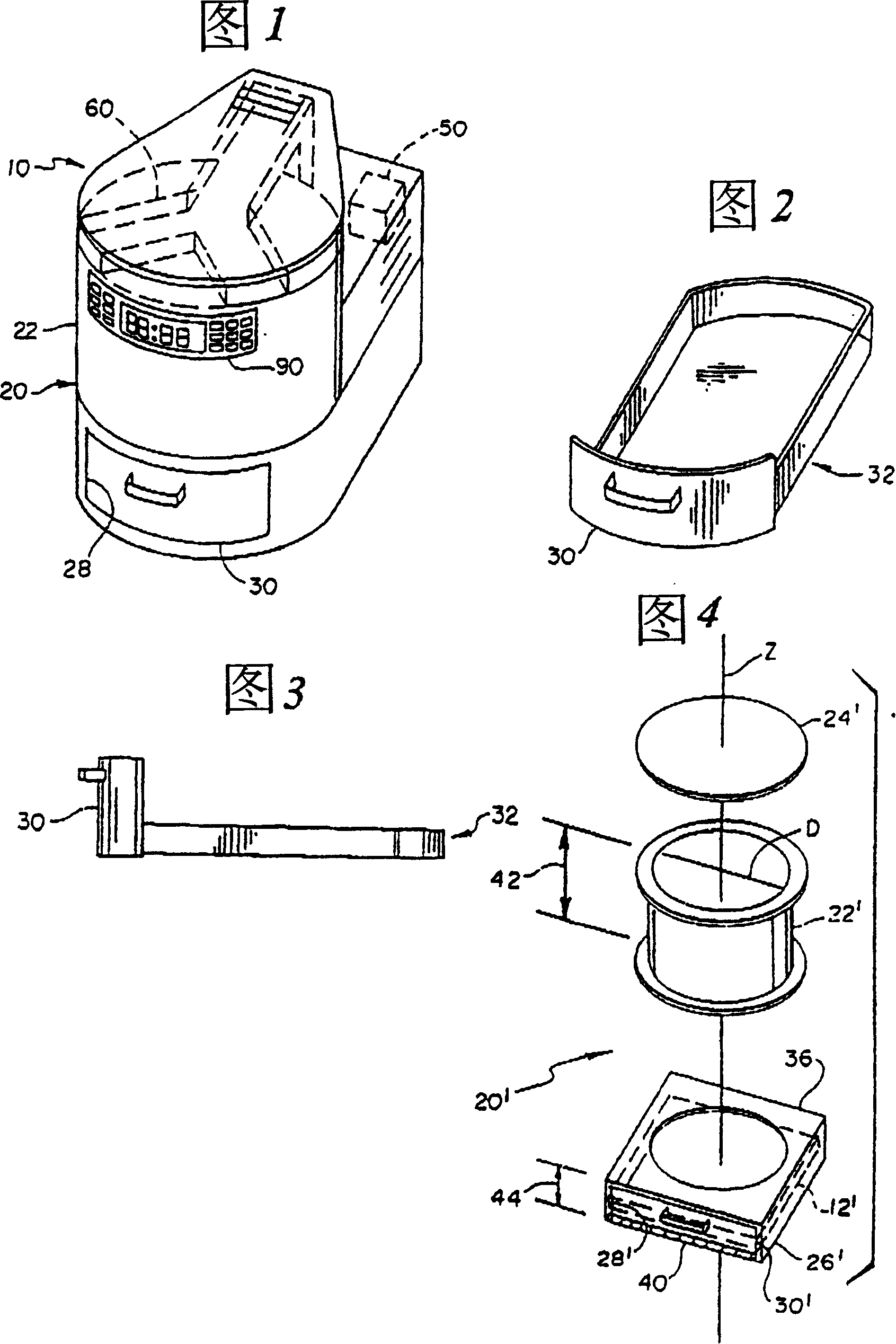

[0066] Figure 1 shows a microwave applicator 10 of the present invention. The applicator 10 includes a microwave containment chamber 20 , an energy source 50 and a feed 60 coupling the energy source 50 to the containment chamber 20 . The energy source 50 is a magnetron or other energy source capable of generating microwaves of a certain frequency, the most commonly used frequency being 2450 MHz or 915 MHz. The electronic control device 90 is for the user to control the working time of the magnetron and set the power of the magnetron. Different powers are usually set by periodically turning on / off the duty cycle of the magnetron.

[0067] Referring to FIGS. 9 and 10 below, the microwave sealed chambe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com