Plasma sterilization device, preparation method of sterilization gas and sterilization method

A technology of plasma and sterilization device, which is applied in the directions of plasma, water supply device, sanitary equipment for toilets, etc., can solve the problems of low sterilization effect and efficiency, short life of active material, low energy utilization rate, etc., and achieves simple structure, The effect of high timeliness and low power cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

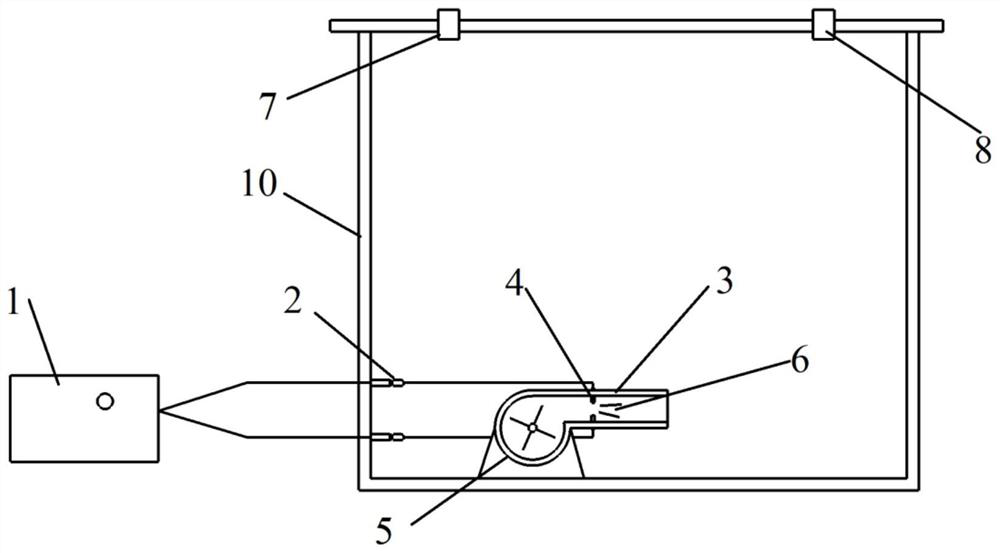

[0051] figure 1 A schematic diagram of Embodiment 1 of the present invention is shown;

[0052] A sterilizing plasma generating device, comprising a sliding arc discharge reactor, an air circulation device 5 and a sealed space 10;

[0053] The air circulation device 5 includes a fan; the air inlet end (not shown) and the air outlet end of the air circulation device 5 communicate with the sealed space 10 respectively, and the air circulation device and the sealed space A sealed communication arrangement is formed through the air inlet end and the air outlet end;

[0054] In this embodiment, it can be seen that the air circulation device 5 is arranged inside the sealed space 10 , that is, it actually constitutes a sealed communication arrangement.

[0055] Specifically, the air circulation device 5 may be a fan itself, and the air inlet and outlet of the fan are the air inlet and outlet of the air circulation device 5 . The air circulation device 5 can also be a fan with a fa...

Embodiment 2

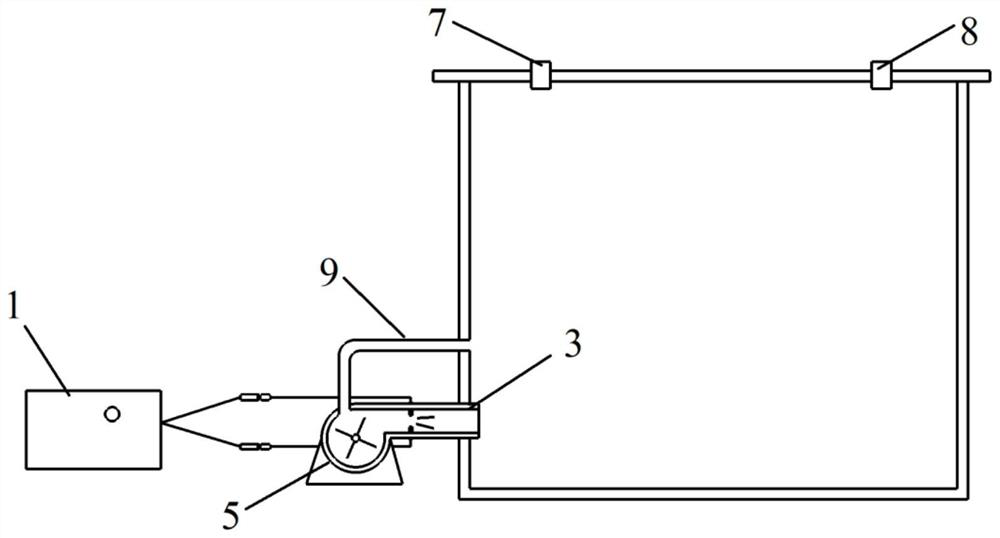

[0071] figure 2 A schematic diagram of Embodiment 2 of the present invention is shown;

[0072] The difference from the first embodiment is that the air circulation device 5 of the second embodiment is arranged outside the sealed space 10 , wherein the outlet end communicates with the sealed space 10 , and the air inlet end communicates with the sealed space through the air return pipe 9 .

Embodiment 3

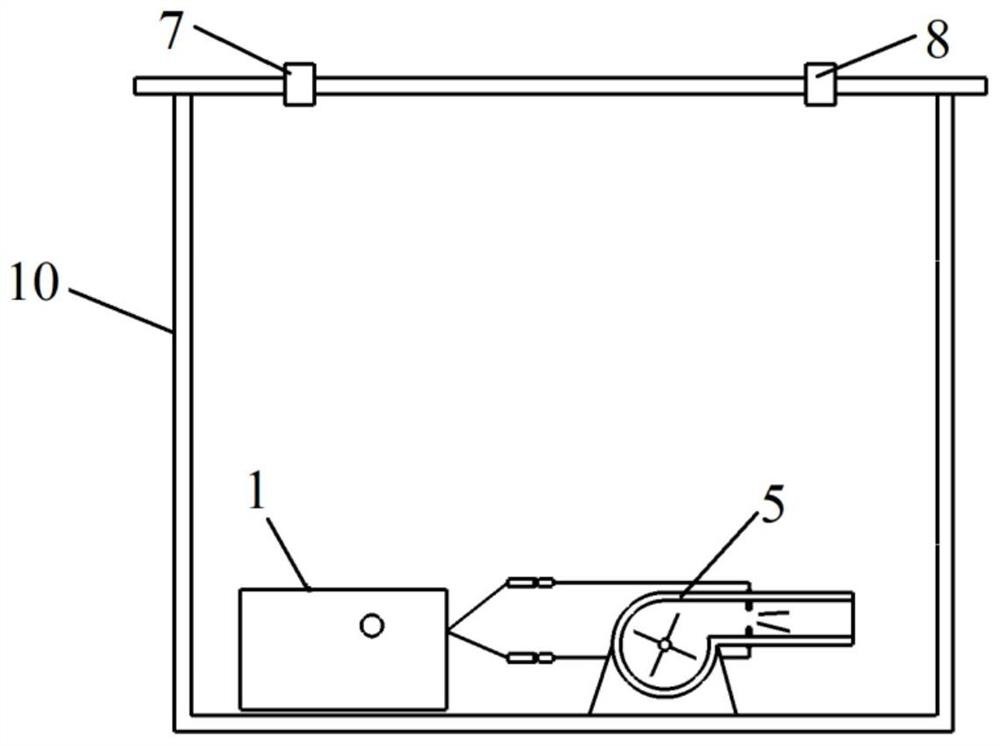

[0074] image 3 A schematic diagram of Embodiment 3 of the present invention is shown;

[0075] Different from Embodiment 1 and Embodiment 2, the power supply 1 and the air circulation device 5 are both arranged inside the sealed cavity, wherein the power supply 1 and the air circulation device 5, wires, and pipelines all need to be treated with corrosion resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com