Circuit board defect detecting and sorting system

A defect detection and sorting system technology, applied in the detection field, can solve problems such as insensitive mechanical arm rotation, easy material falling off the workbench, cumbersome camera replacement, etc., to achieve the effects of reducing dazzling lights, stable workpieces, and easy loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

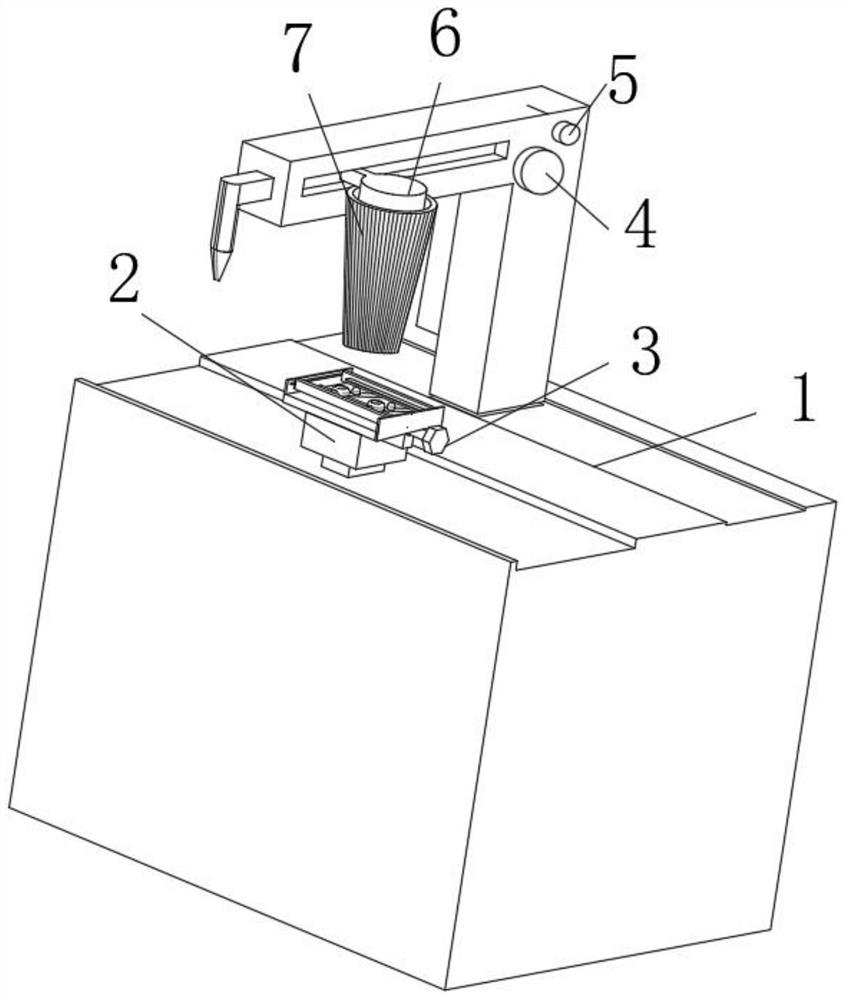

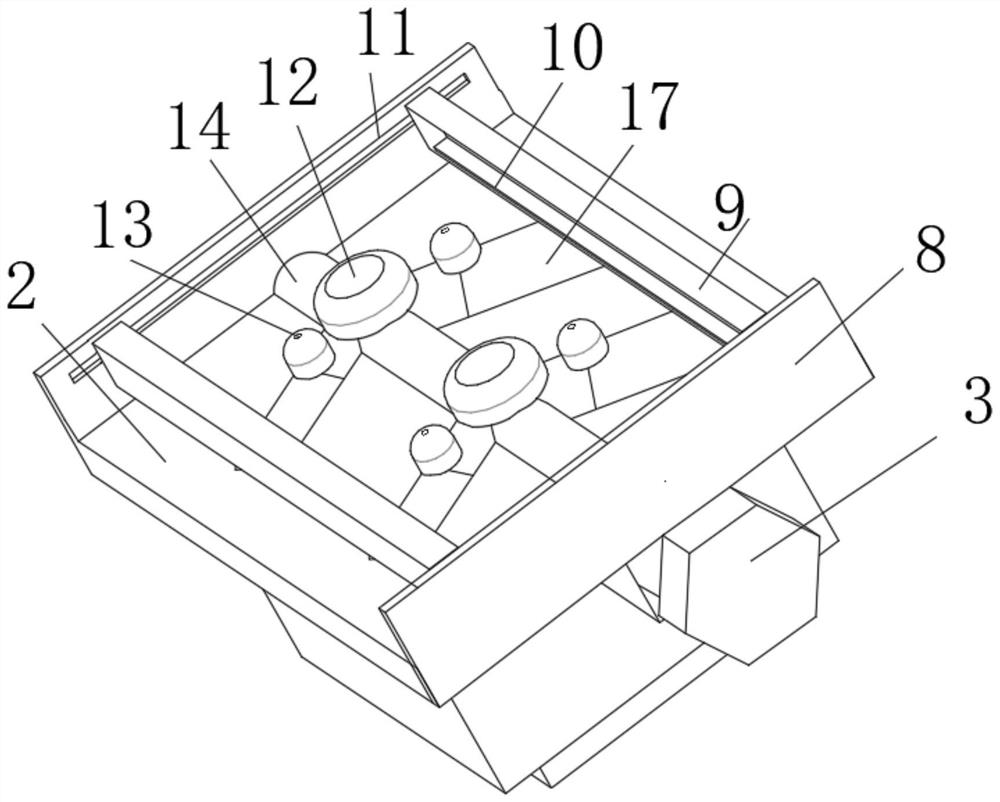

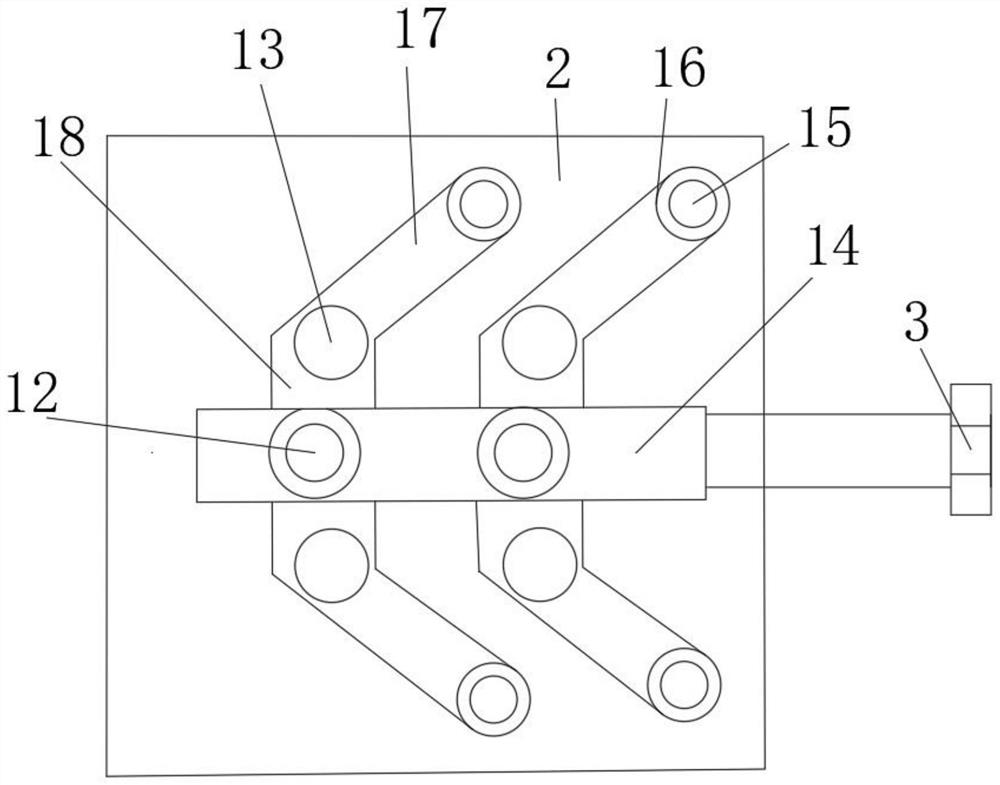

[0023] see Figure 1-6 , the present invention provides the following technical solutions: a circuit board defect detection and sorting system, the instrument main body 1 is provided with a workbench 2, both ends of the workbench 2 are provided with baffles 8, the baffles 8 are connected to the fixed plate through the chute 11 9. One end of the fixed plate 9 is provided with a boss 10, the bottom of the fixed plate 9 is connected with the No. 1 connecting rod 16, and the No. 1 connecting rod 16 is connected with the No. 2 connecting rod 17 through the No. 17 is connected with the bump 18 through the second rotating shaft 13, the front end of the workbench 2 is provided with a bolt 3, one end of the bolt 3 is connected with the bushing 14, and the bushing 14 is provided with the No. 1 rotating shaft 12, and the upper end of the main body 1 of the instrument is provided with a drive shaft 4. A driven shaft 5 is also provided. One end of the driving shaft 4 is provided with a gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com