Flexible film circular symmetry circumferential pre-tightening device

A flexible film, circular symmetry technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of optical lens application, poor mechanical strength and surface stability, etc., to improve the degree of locking, avoid stress concentration, avoid irreproducible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

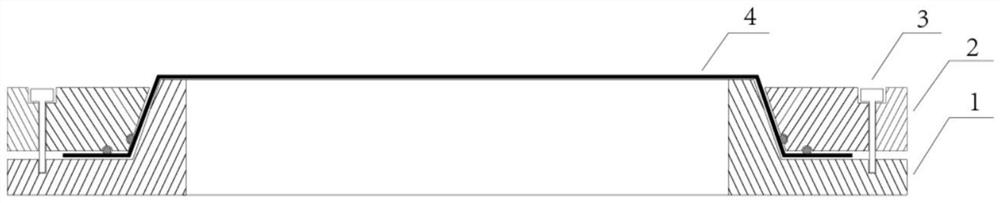

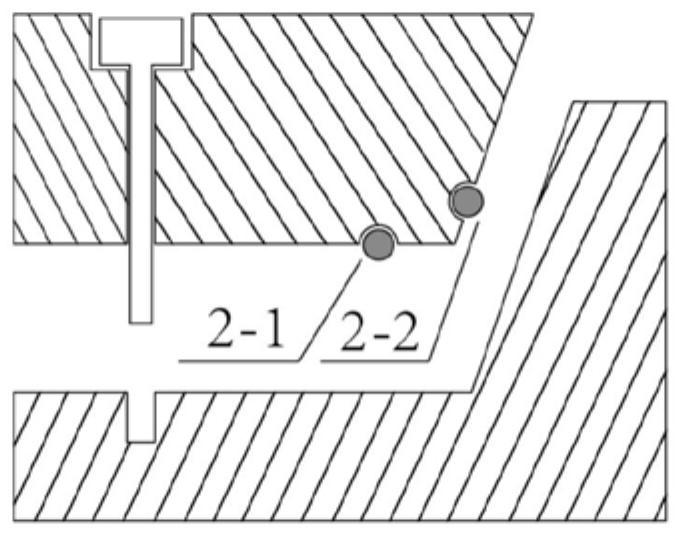

[0021] A circularly symmetrical circumferential pretensioning device for a flexible film of the present invention, comprising an annular base 1, a pressure ring 2, a bottom rubber ring 2-1, an inner rubber ring 2-2, fastening bolts 3, and a flexible film 4; The annular base 1 supports the flexible film 4 as the main structure and is connected with the pressure ring 2 through the fastening bolt 3. The pressure ring 2 exerts a frictional force on the flexible film 4 through the embedded inner rubber ring 2-2 to realize circumferential pretension, and The flexible film 4 is firmly locked by applying positive pressure through the embedded bottom rubber ring 2-1. The fastening bolts 3 are evenly distributed on the annular base 1 and the pressure ring 2, the flexible film 4 is clamped in the gap between the pressure ring 2 and the annular base 1, and the edge of the flexible film 4 is located on the bottom side of the pressure ring. The fastening bolt 3 section is not in contact wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap