Salad making machine for food processing

A food processing and salad technology, applied in metal processing, food forming, application, etc., can solve the problems of staff injury, long production time, and low work rate, so as to improve work efficiency, reduce trouble, The effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

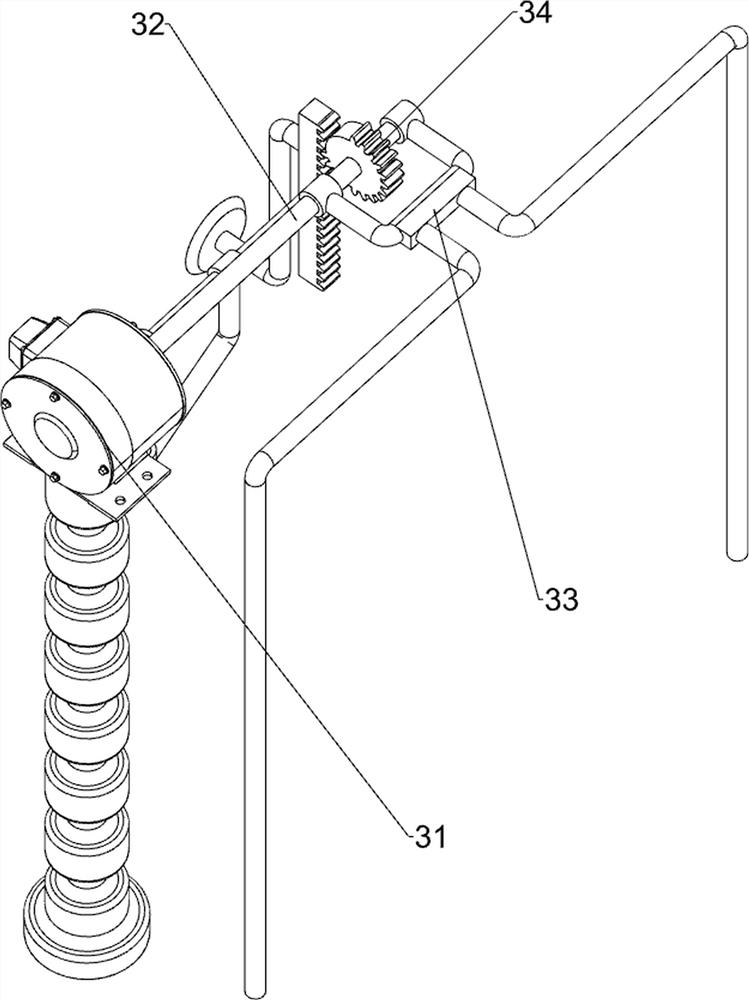

[0029] A salad making machine for food processing, such as Figure 1 to Figure 3 As shown, a base plate 1, a cutting mechanism 2 and an automatic cutting mechanism 3 are included, the upper side of the base plate 1 is provided with the cutting mechanism 2, and the upper side of the base plate 1 is provided with the automatic cutting mechanism 3.

[0030] When cutting the food, the food is placed on the cutting mechanism 2, and then the automatic cutting mechanism 3 is started, and the automatic cutting mechanism 3 will drive the cutting mechanism 2 to cut the food, so that no manual personnel are required to cut the food, and the work efficiency is improved. When the material cutting is completed, close the automatic cutting mechanism 3 and get final product.

[0031] The cutting mechanism 2 includes a placing frame 21, a connecting support rod 22, a sliding rack 23, a cutting knife 24 and a first spring 25. The upper side of the middle part of the base plate 1 is provided wit...

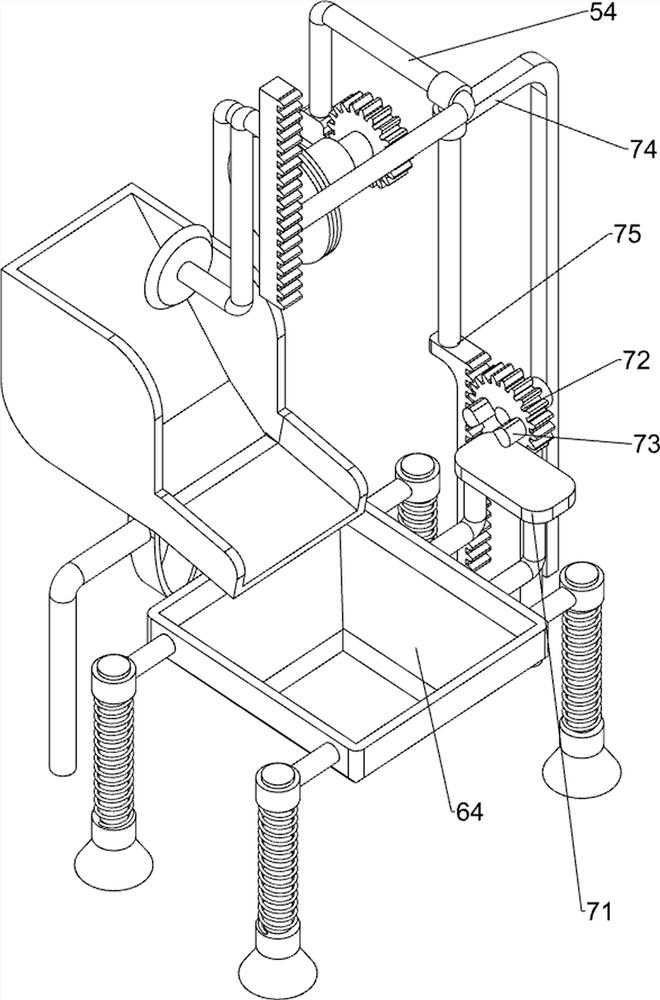

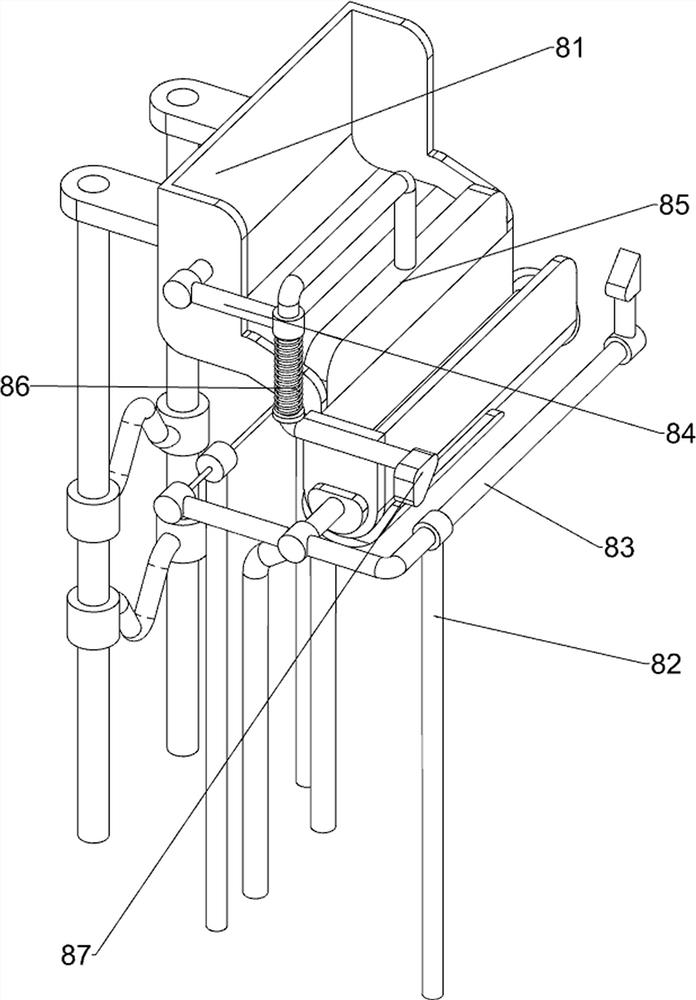

Embodiment 2

[0036] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, a cutting and pressing mechanism 4 is also included. The cutting and pressing mechanism 4 includes a first fixed sliding sleeve 41, a sliding pressing plate 42, a second spring 43 and a driving rod 44. The first fixed sliding sleeve 41, the sliding pressing plate 42 is slidably connected between the first fixing sliding sleeve 41, the second spring 43 is connected between the first fixing sliding sleeve 41 and the sliding pressing plate 42, the lower side of the sliding rack 23 is connected Drive bar 44 is arranged, and sliding pressing plate 42 cooperates with drive bar 44.

[0037] Starting the motor 31 will cause the sliding rack 23 to move downward, thereby causing the driving rod 44 to move downward, and then contact the sliding pressing plate 42, thereby driving the sliding pressing plate 42 to move downward, thereby causing the second spring 43 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com