Intaglio printing method for surface of pre-compounded aluminum foil

A technology of gravure printing and printing method, applied in the field of aluminum foil printing, can solve the problems of wrinkling or material breakage, low single-layer processing efficiency, etc., and achieve the effects of enhancing fastness, simple printing method and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

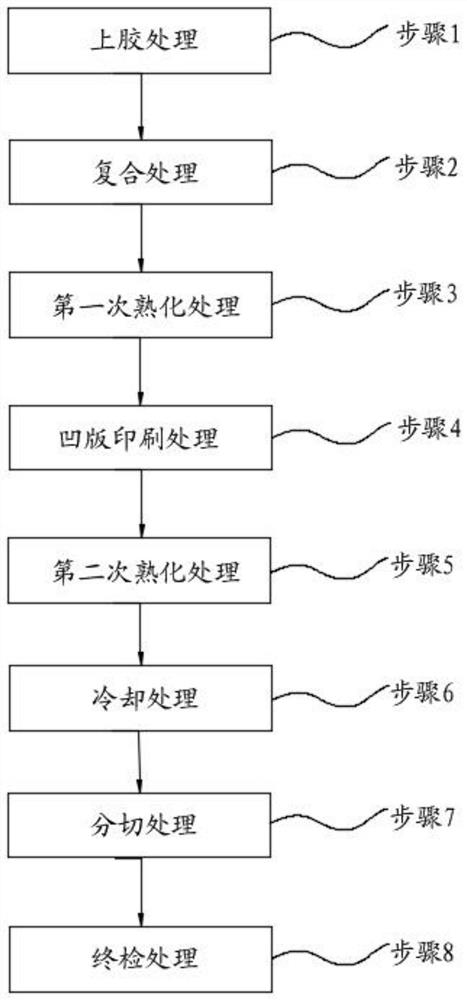

[0056] The invention provides a method of gravure printing on the surface of aluminum foil after pre-compositing, and the details of the printing method are as follows:

[0057] Step 1) Gluing treatment: Glue the 20μm thick LLDPE through the glue roller on the printing machine. The glue used for gluing is adhesive. The type and ratio of adhesive are SY-03G: SY-03B: ethyl ester = 20:4.8:28;

[0058] Step 2) Composite treatment: Laminate the glued LLDPE and AL aluminum foil with a thickness of 20 μm to form a 0.02mmAL aluminum foil / 0.02mmLLDPE semi-finished composite film;

[0059] Step 3) The first aging treatment: the 0.02mmAL aluminum foil / 0.02mmLLDPE semi-finished composite film made by compounding in step 2 is sent to the material rack of the curing room for hanging curing, and the semi-finished composite film is suspended on the material rack of the curing room. The time is 30 hours, and the temperature for curing in the curing chamber is 45°C;

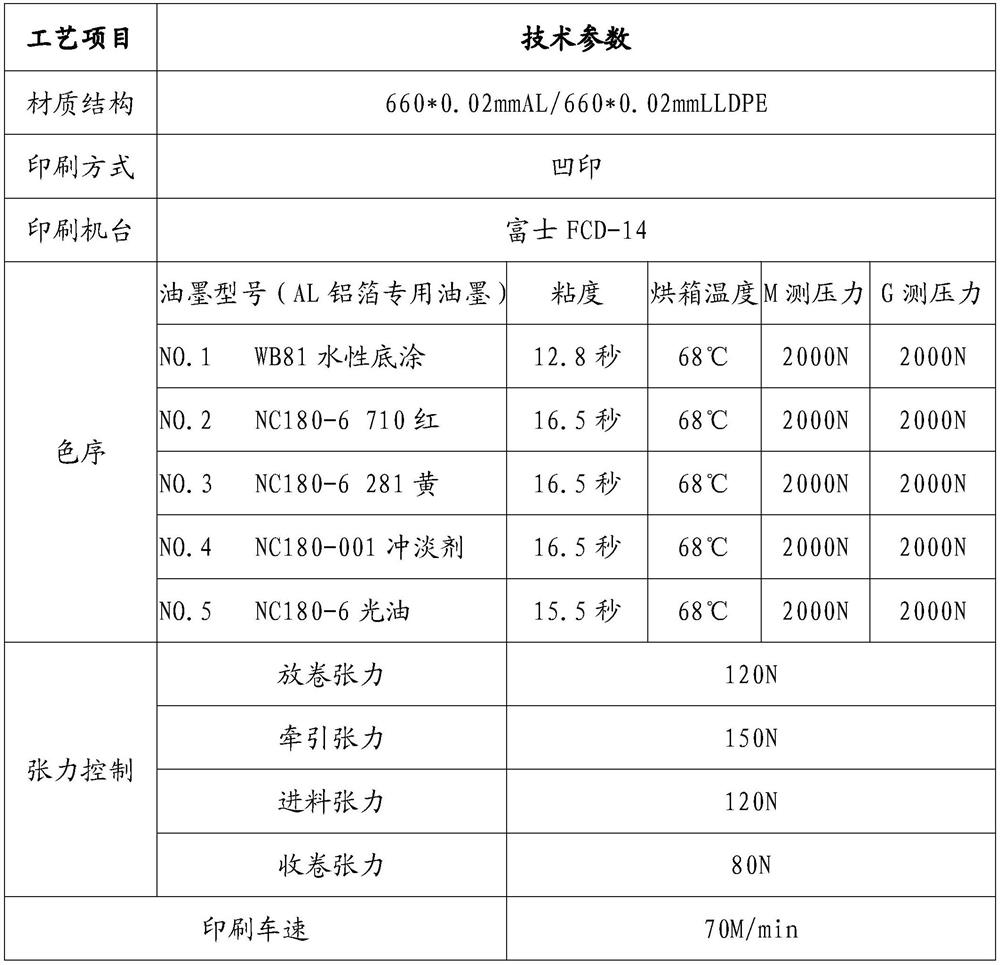

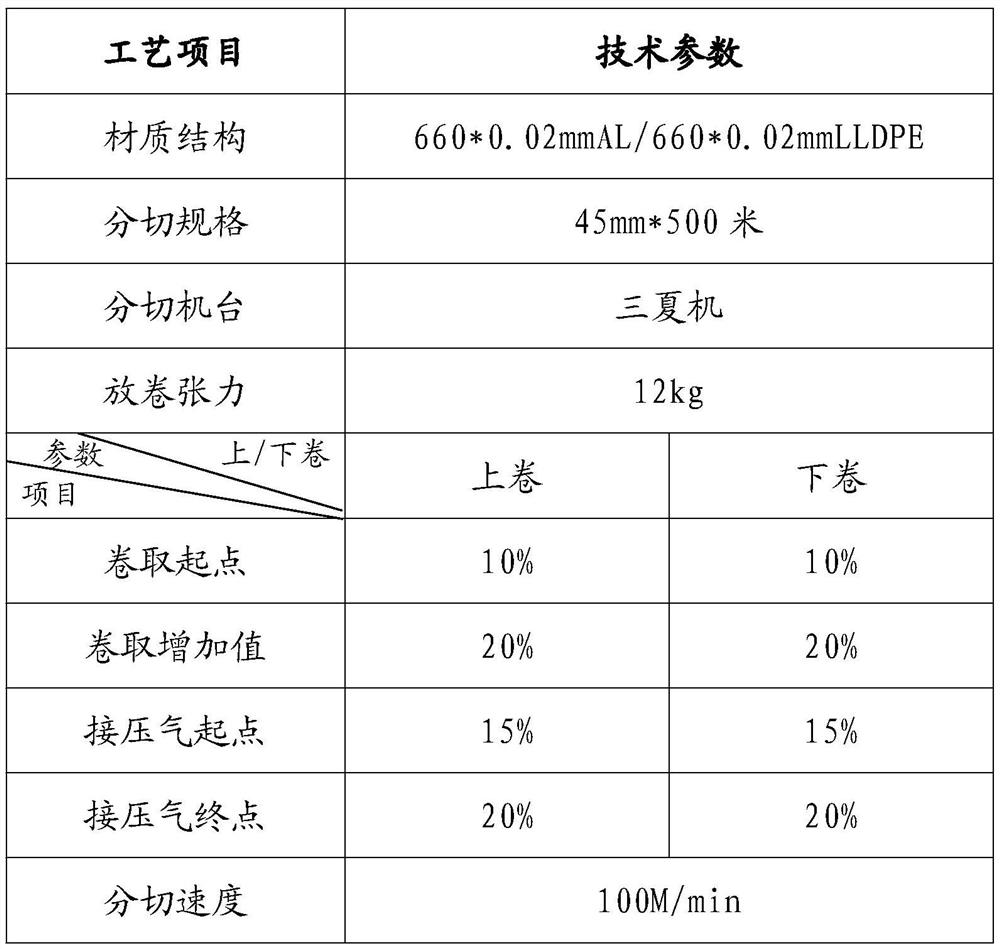

[0060] Step 4) Gravure p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com