A tunnel boring machine and its support shoe device

A technology for tunnel boring machines and tunnels, which is applied in tunnels, mining equipment, earthwork drilling and mining, etc. It can solve the problems of weak and broken surrounding rock areas that cannot be effectively supported, and the support area is fixed, so as to improve the passing rate and increase the support. Top area, effect of reducing reaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

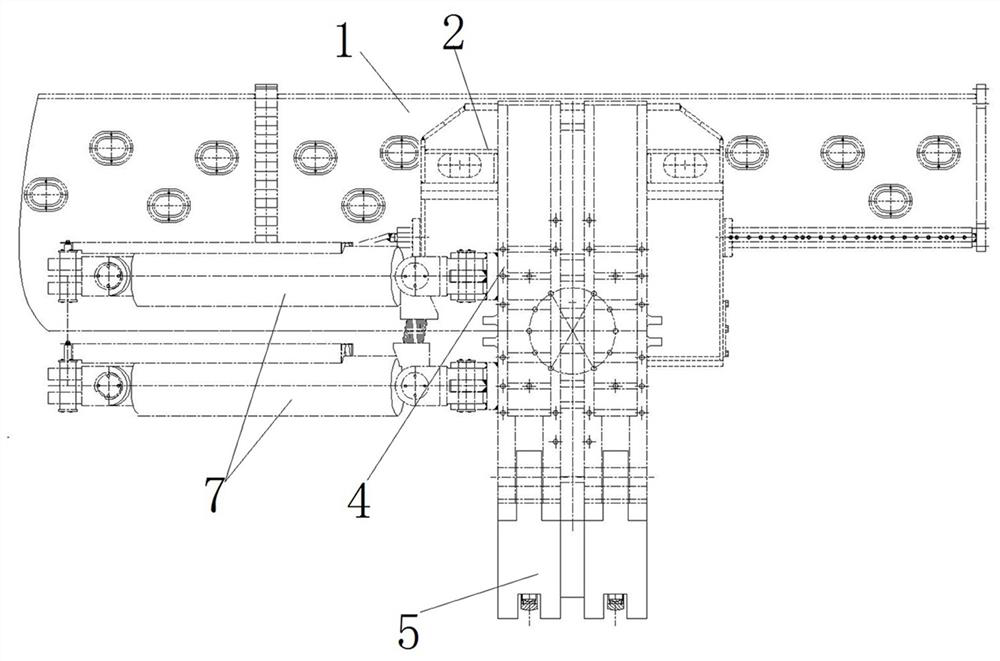

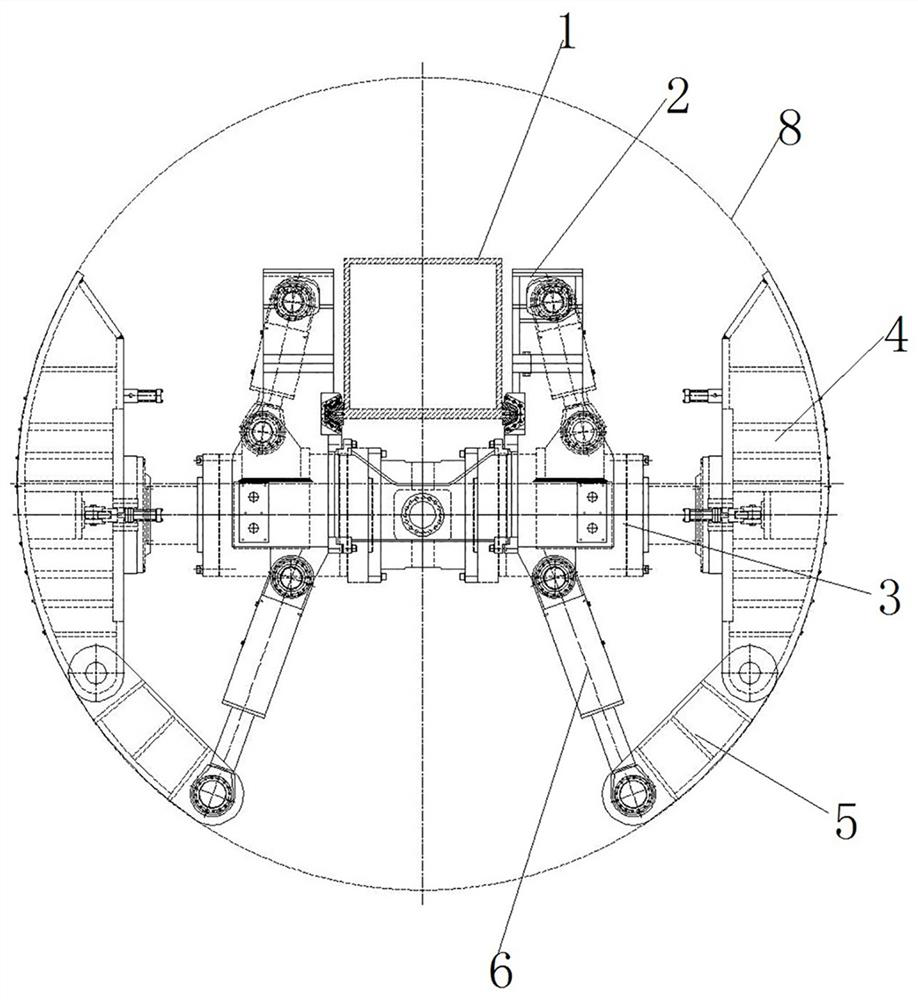

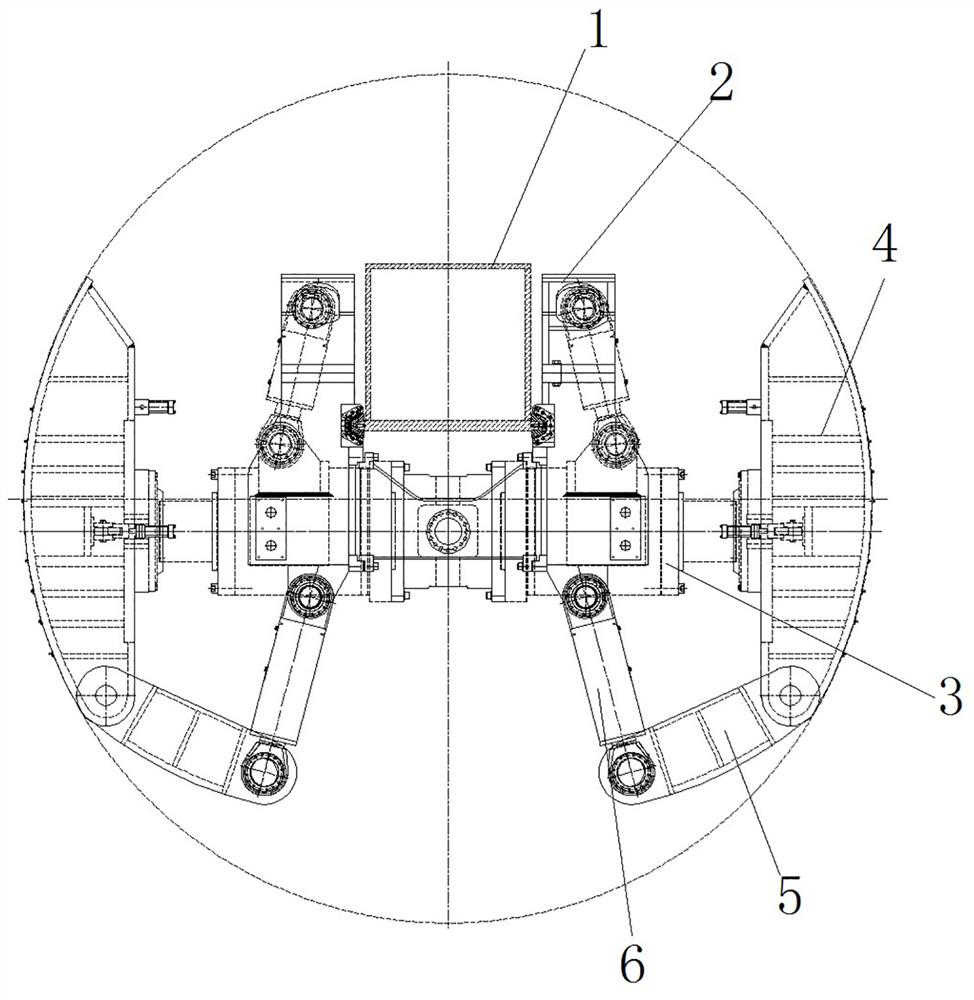

[0053] like figure 1 , figure 2 and image 3 As shown, the tunnel boring machine in this embodiment is an open-type TBM, and the TBM includes a main beam 1 . The front end of the main beam 1 is provided with a main drive, which is used to drive the cutter head to rotate and excavate the tunnel 8 . The structures of the main beam 1 , the main drive and the cutter head are the same as the corresponding structures of the main beam 1 , the main drive and the cutter head of the TBM in the prior art, and will not be repeated here.

[0054] A walking track is arranged on the main beam 1, the walking track extends along the extension direction of the main beam 1, and a support shoe device is installed on the main beam 1. The support shoe device here is a horizontal floating support shoe structure, and the support shoe device specifically includes a saddle Frame 2, the saddle frame 2 is movably assembled on the walking track of the main beam 1, the saddle frame 2 is provided with ma...

specific Embodiment 2

[0066] The main difference between it and Embodiment 1 is that in Embodiment 1, each side of the main support shoe is only hinged at the lower end of the auxiliary support shoe. In this embodiment, since the upper side space of the main bracer shoe is also unused, the auxiliary bracer shoe can be hinged at the upper end of the main bracer shoe, and at this time, the auxiliary bracer shoe cylinder is arranged on the upper side.

[0067] Of course, in other embodiments, the upper auxiliary support shoe may be hingedly connected to the upper end of each side main support shoe, and the lower auxiliary support shoe may be hinged to the lower end of each side main support shoe, and corresponding to each auxiliary support shoe may be provided separately Auxiliary shoe cylinder to drive auxiliary shoe swing.

specific Embodiment 3

[0069] The main difference from Embodiment 1 is that in Embodiment 1, the auxiliary support shoe is hingedly assembled with the main support shoe. In this embodiment, referring to the X-shaped support shoe structure, an auxiliary support shoe oil cylinder is fixed on the saddle frame, and the auxiliary support shoe oil cylinder expands and contracts along the radial direction of the tunnel. At this time, the auxiliary support shoe can be completely driven by the auxiliary support shoe oil cylinder Extending and directing along the radial direction of the tunnel, at this time, there is no direct connection between the auxiliary support shoe and the main support shoe, and both are installed on the saddle. When passing through the weak and broken surrounding rock area, the auxiliary support shoe cylinder drives the auxiliary support shoe to extend straight to support the tunnel. The boots can be retracted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com