High-temperature and high-pressure conventional triaxial direct shear fracture seepage coupling testing device and use method

A high-temperature and high-pressure, testing device technology, applied in measuring devices, using stable shear force to test material strength, using stable tension/pressure to test material strength, etc. Shear rupture permeability test and other problems, to achieve the effect of simple structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings. Among them, the directional nouns such as "up" and "down" mentioned in this article are based on figure 1 orientation as a reference.

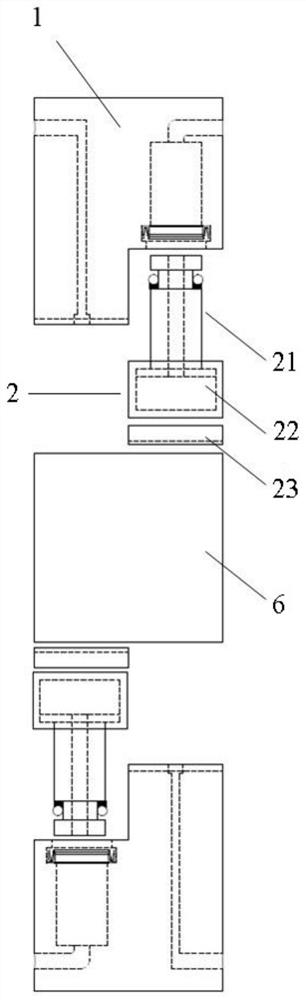

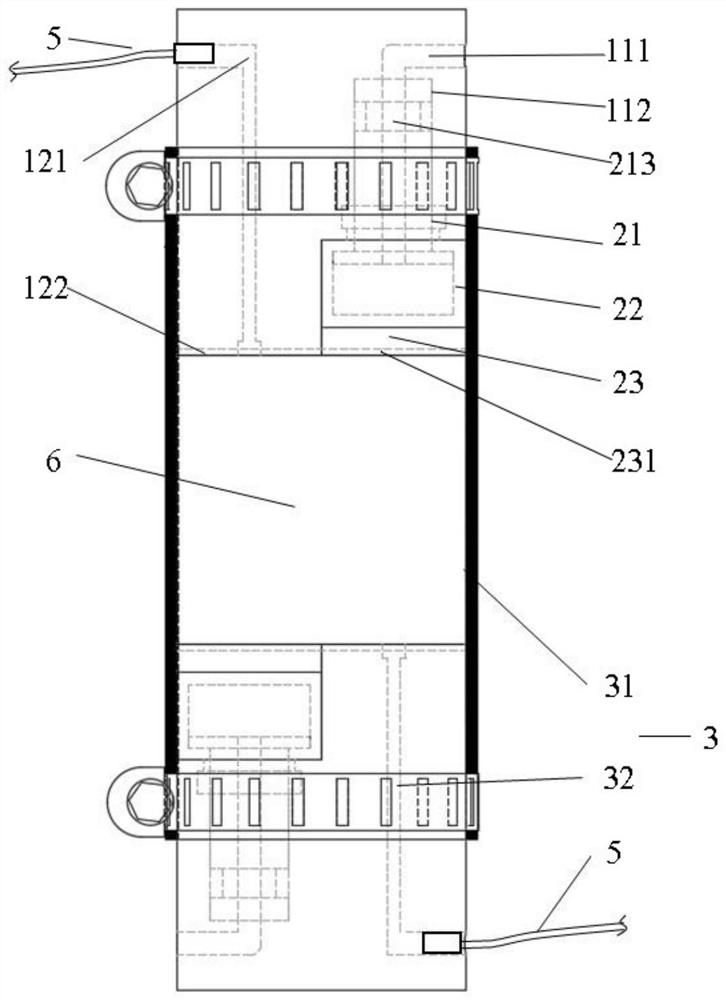

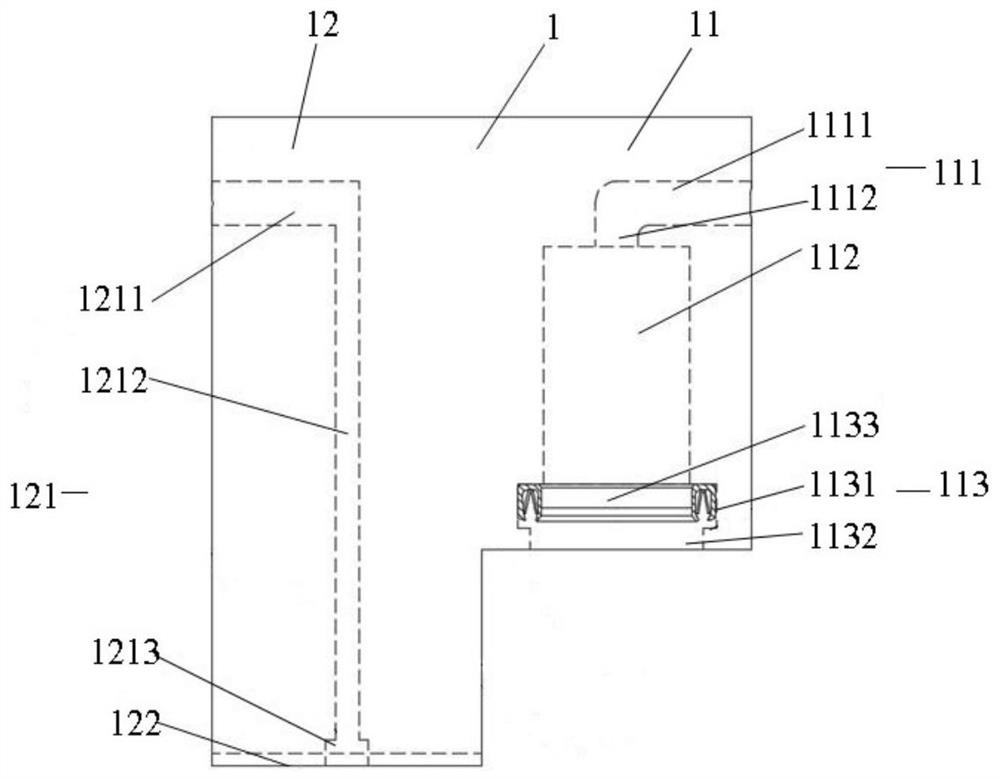

[0078] refer to figure 1 and figure 2 , the embodiment of the present invention proposes a high temperature and high pressure conventional three-axis direct shear fracture-seepage coupling test device, including two shear indenters 1, two pressure components 2, a fixing component 3 and a pipetting component 4.

[0079] The two shear indenters 1 and the two pressure assemblies 2 are respectively arranged on the upper and lower sides of the rock sample 6 in a symmetrical manner with respect to the center of the rock sample 6 . The fixed component 3 is sleeved on the rock sample 6, two shear pressure heads 1 and two pressure com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com