Evaluation method for initial viscosity of formaldehyde-free adhesive

A technology for formaldehyde-free adhesives and evaluation methods, which is applied in the preparation, sampling, and measuring devices of test samples, and can solve the problems of not being able to effectively reflect the initial tackiness of plywood glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Under normal temperature conditions (25°C / 50% humidity), select a eucalyptus veneer with a thickness of 1.7mm and a moisture content of 15%, cut it into a 50*150mm sample A for testing the bonding strength, and a 40*40cm sample B For hot pressed boards;

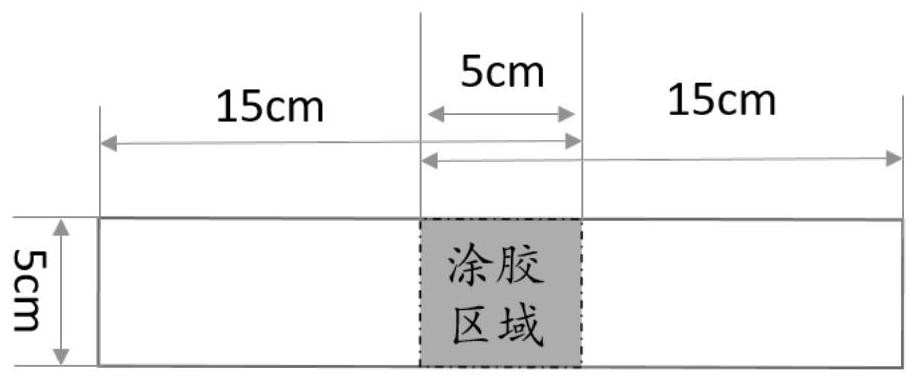

[0042] According to 210g / m 2 (The adhesive is Wanhua's self-made formaldehyde-free adhesive-two-component polyurethane glue), evenly coated on the 50*50mm area of model A and the entire surface of model B. Wherein, model A has two layers, and model B has 5 layers), after the billet is assembled, carry out smooth covering pressing with the pressure of 0.005MPa, obtain the covering pressing plate;

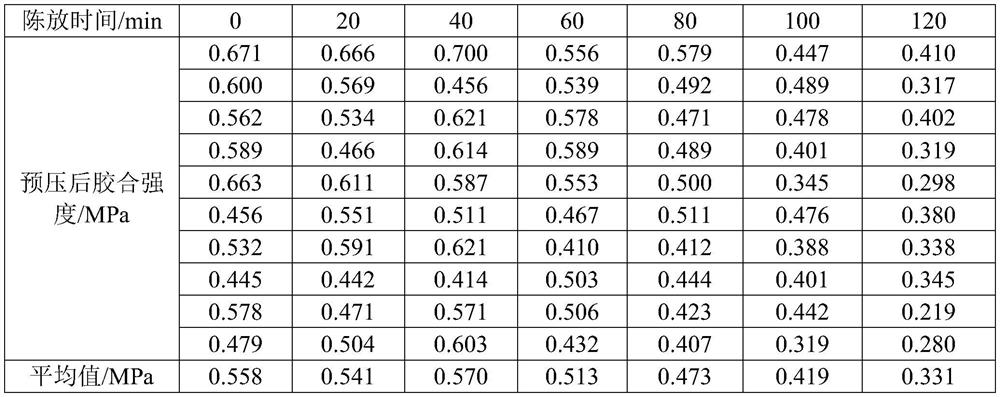

[0043] Divide the cladding panels into 7 groups, each group has cladding panels A' formed by 10 samples A and cladding panels B' formed by 1 sample B, and then according to the aging time of 0 min (that is, the group blanks are directly pre-pressed after cladding, The average bonding strength of the pre-compressed board A...

Embodiment 2

[0046] Under normal temperature conditions (25°C / 50% humidity), select eucalyptus veneers with a thickness of 2.1mm and a moisture content of 8% to cut into a 50*150mm sample A for testing the bonding strength, and a 40*40cm sample B For hot pressed boards;

[0047] According to 190g / m 2 The amount of glue applied (adhesive is bean glue), evenly coated in the 50*50mm section of model A and the entire surface of model B, after the glue is applied, directly form the billet (among them, model A is two layers, model B 5 layers), after forming the billet, carry out flat covering pressing with a pressure of 0.003MPa to obtain a covering plate;

[0048]Divide the laminated boards into 5 groups, each group has 10 laminated boards formed by model A and 1 laminated board formed by model B, and then according to the aging time of 0min, 30min, 60min, 90min and 120min, put a group of laminated boards at intervals of 30min The pressure plate is preloaded, and the preloading condition is 0...

Embodiment 3

[0051] Under normal temperature conditions (25°C / 50% humidity), select eucalyptus veneers with a thickness of 3mm and a moisture content of 10% to cut into a 50*150mm sample A for testing the bonding strength, and a 40*40cm sample B for testing on hot-pressed plates;

[0052] According to 220g / m 2 The amount of glue applied (adhesive is EPI glue), evenly coated in the 50*50mm area of model A and a whole surface of model B, after the glue is applied, the billet is directly formed (among them, model A is two layers, model B 5 layers), after the billet is assembled, the pressure of 0.01MPa is used for flat covering.

[0053] The cladding plates are divided into 7 groups, each group has 10 cladding plates formed by model A and 1 cladding plate formed by model B, and then pre-pressed according to 0min (that is, the group blanks are directly pre-pressed after laminating, the gluing of the cladding plates in this group The average strength can be used as the initial pre-compressi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com