Three-hole box culvert group internal force analysis method suitable for long-distance water conveyance project

A technology for long-distance water delivery and internal force analysis, applied in special data processing applications, force/torque/power measuring instruments, measuring devices, etc. Problems such as the state and health of the culvert group structure, to achieve the effect of simplicity, flexibility, practicability, simple operation, and reduced calculation workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

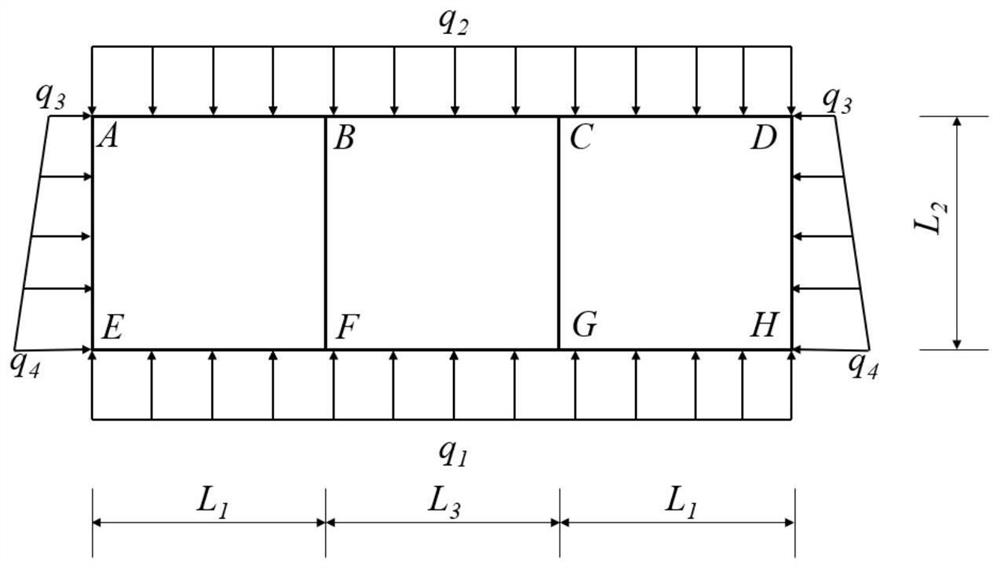

Method used

Image

Examples

Embodiment 1

[0129] A long-distance water transfer project is 35km long, and there are 121 three-hole box culverts, forming a box culvert group. In the design stage, the calculation program for the internal force of the three-hole box culvert of the present invention is easy to operate and accurate, and the calculation speed is fast. As long as the basic data is input into the computer, the calculation result will be obtained immediately, the calculation workload is reduced, and the design efficiency is increased by more than 120%. .

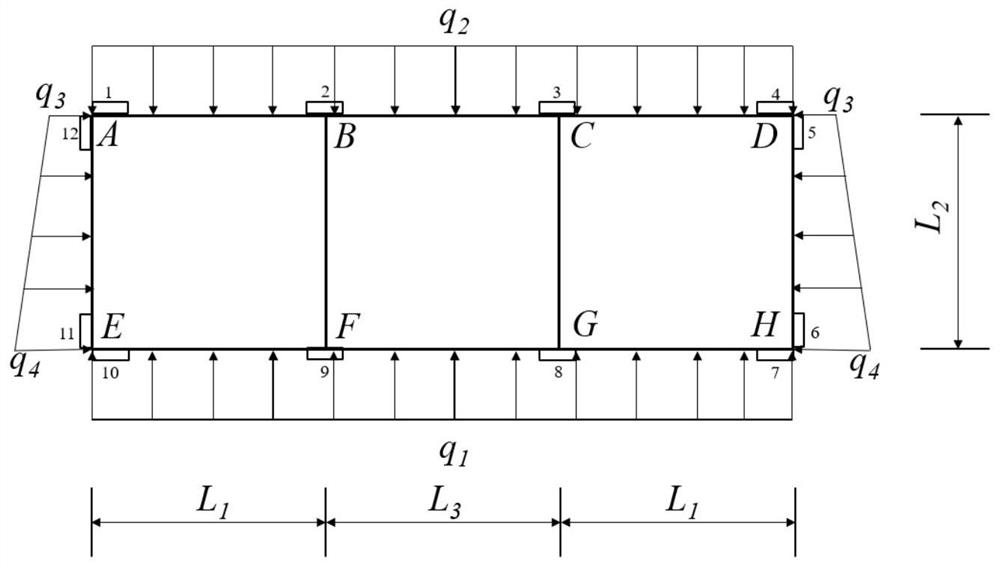

[0130] Combine below image 3 with Figure 4 The specific implementation steps in the design phase are as follows:

[0131] (1) Calculate the unit stiffness of each member according to the actual three-hole box culvert, and input the unit stiffness to Figure 4 Middle ① unit stiffness parameter input area;

[0132] (2) Calculate the fixed end bending moment according to the actual load of the three-hole box culvert, and input the calculation result of th...

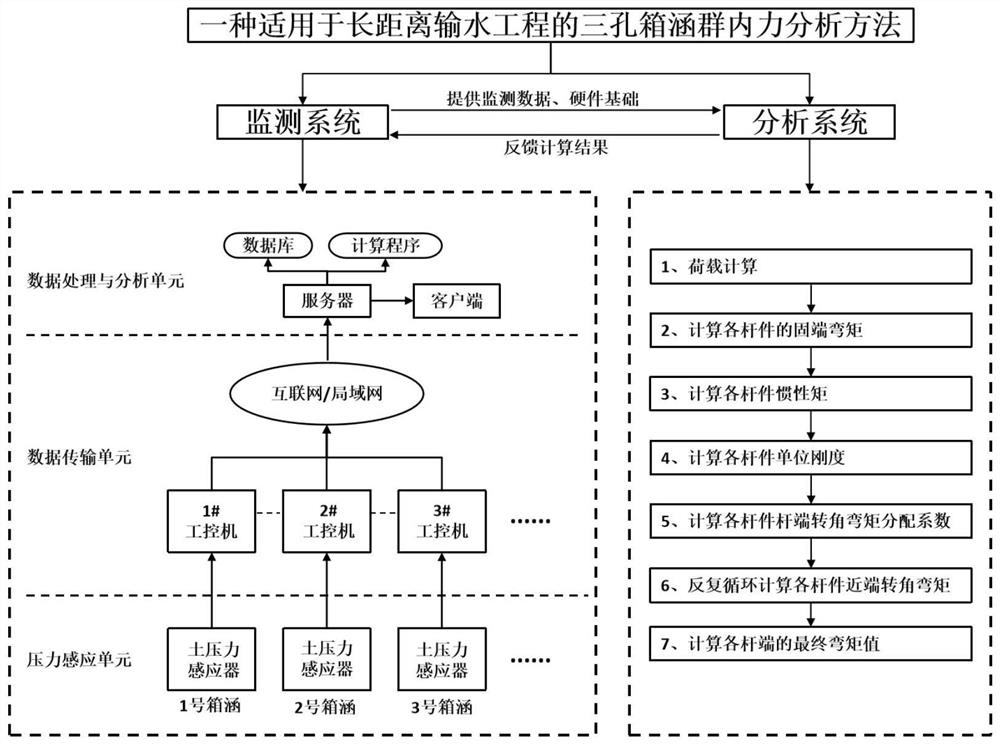

Embodiment 2

[0137] A long-distance water transfer project is 35km long, and there are 121 three-hole box culverts, forming a box culvert group. In the operation stage, the present invention can effectively monitor the health status of the entire engineering box culvert group, and provide a basis for early warning of safety risks. Combine below figure 2 with image 3 The specific implementation steps in the operation phase are as follows:

[0138] (1) During the construction of each three-hole box culvert, earth pressure sensors are pre-embedded at the junctions of side walls and roofs, middle walls and roofs, side walls and low plates, and middle walls and bottom plates. The specific positions are as follows image 3 The numbers 1 to 12 in the middle;

[0139] (2) In the operation stage, the pressure sensing unit of each box culvert integrates and transmits the data monitored by the sensor through the industrial computer of the data transmission unit, and sends it to the data processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com