Prefabricated transformer substation noise reduction device

A prefabricated substation and noise reduction technology, which is applied in the field of substation noise reduction, can solve the problems of substation users' daily life adverse effects, loud noise, metal structure disturbance, etc., achieve good noise reduction effect, release vibration energy, and reduce energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

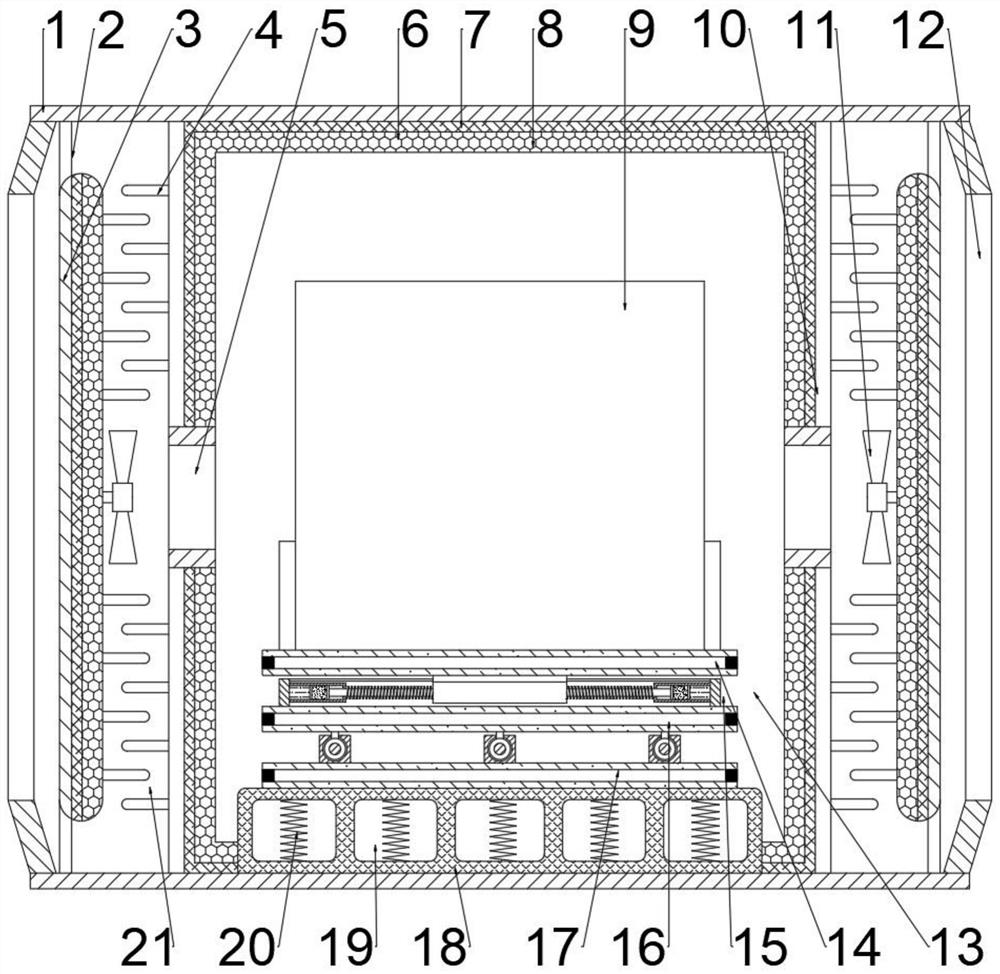

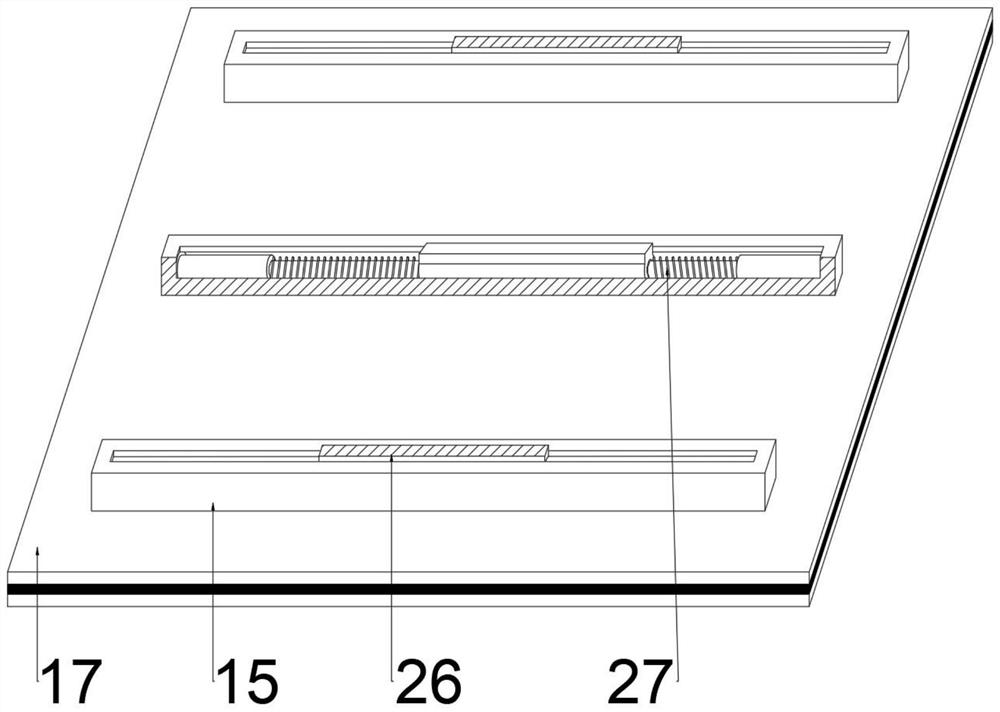

[0030] see Figure 1~3 , in Embodiment 1 of the present invention, a prefabricated substation noise reduction device includes a housing 1 and a noise reduction mechanism 13; a buffer base 18 and a noise reduction mechanism 13 are fixedly connected inside the housing 1; The noise mechanism 13 includes a primary buffer plate 17, a secondary buffer plate 16, a tertiary buffer plate 14 and a shock absorber 15; the primary buffer plate 17, the secondary buffer plate 16 and the tertiary buffer plate 14 are all hollow structures There are multiple groups of shock absorbing devices 15 arranged in parallel fixed between the primary buffer plate 17 and the secondary buffer plate 16, and multiple groups of parallel shock absorbers 15 are fixed between the secondary buffer plate 16 and the tertiary buffer plate 14. The shock absorber 15, and the shock absorber 15 is perpendicular to the shock absorber 15 between the primary buffer plate 17 and the secondary buffer plate 16; the shock abso...

Embodiment 2

[0035]see Figure 1~5 , the main difference between this embodiment 2 and embodiment 1 is:

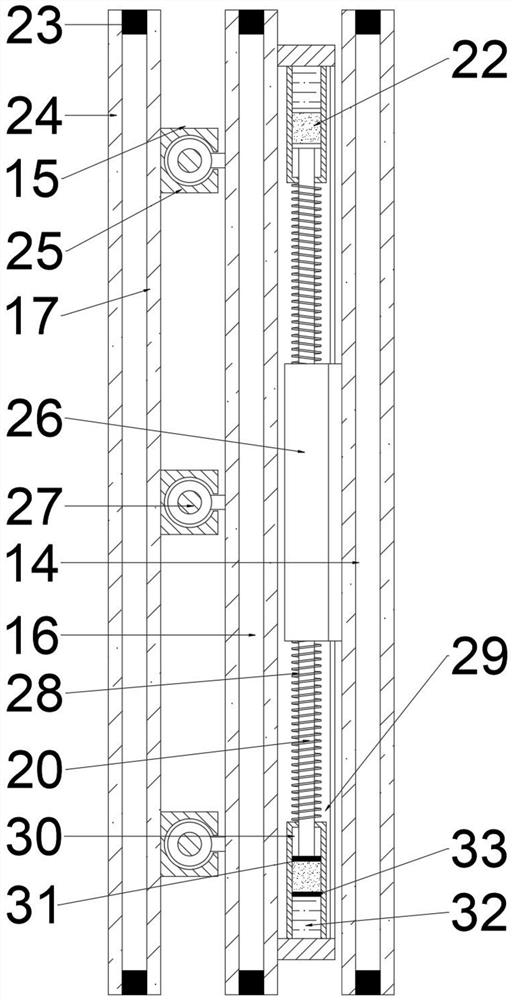

[0036] see Figure 1~3 , in Embodiment 2 of the present invention, the track block 26 is embedded in the track groove 25 of the shock absorbing device 15 , and the two ends of the track block 26 are connected to the two ends of the track groove 25 through a buffer assembly 27 . The damping device 15 is located between the interlayers, and the track groove 25 and the track block 26 are respectively connected to the mounting plates 24 on both sides. When the vibration occurs, the mounting plate 24 above drives the track block 26 to vibrate, and the vibration of the track block 26 can be decomposed into driving The energy of the vibration of the track groove 25 and the energy released by the track groove 25, when the track block 26 moves along the track groove 25, the buffer assemblies 27 at both ends deform to absorb the vibration energy and weaken the vibration.

[0037] see Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com