Use of starch mixture in dairy product

A technology for mixtures, dairy products, applied in the direction of dairy products, bacteria used in food preparation, milk preparations, etc., which can solve problems not considered or classified as chemical modification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

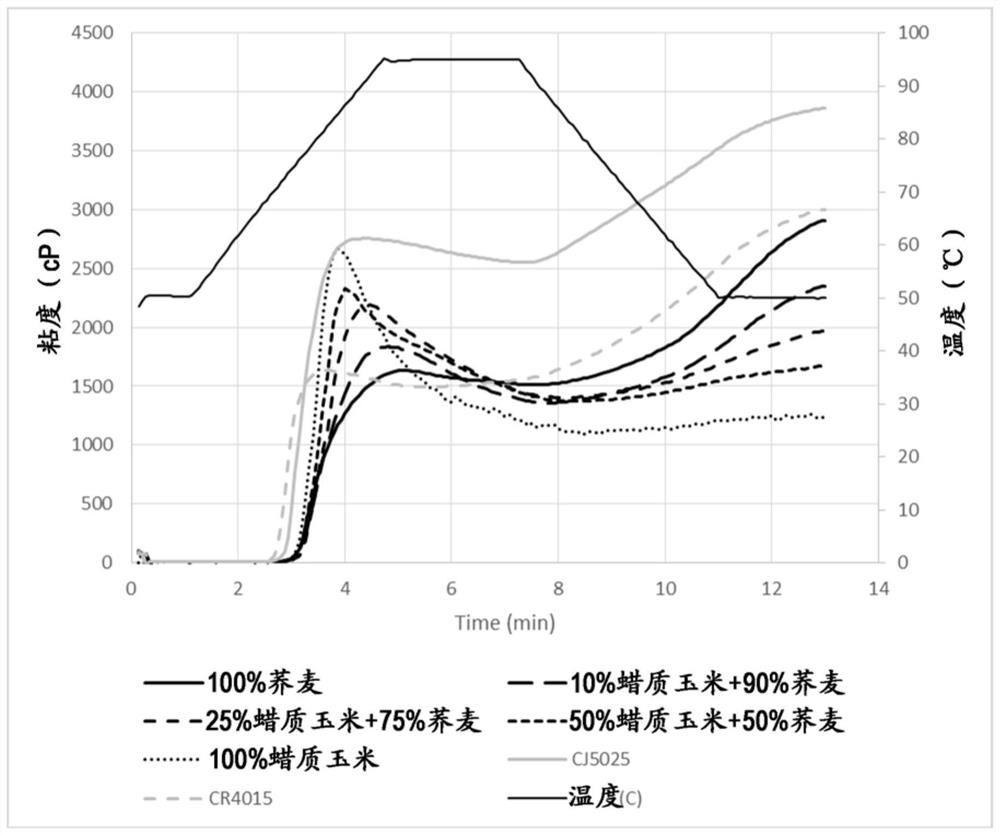

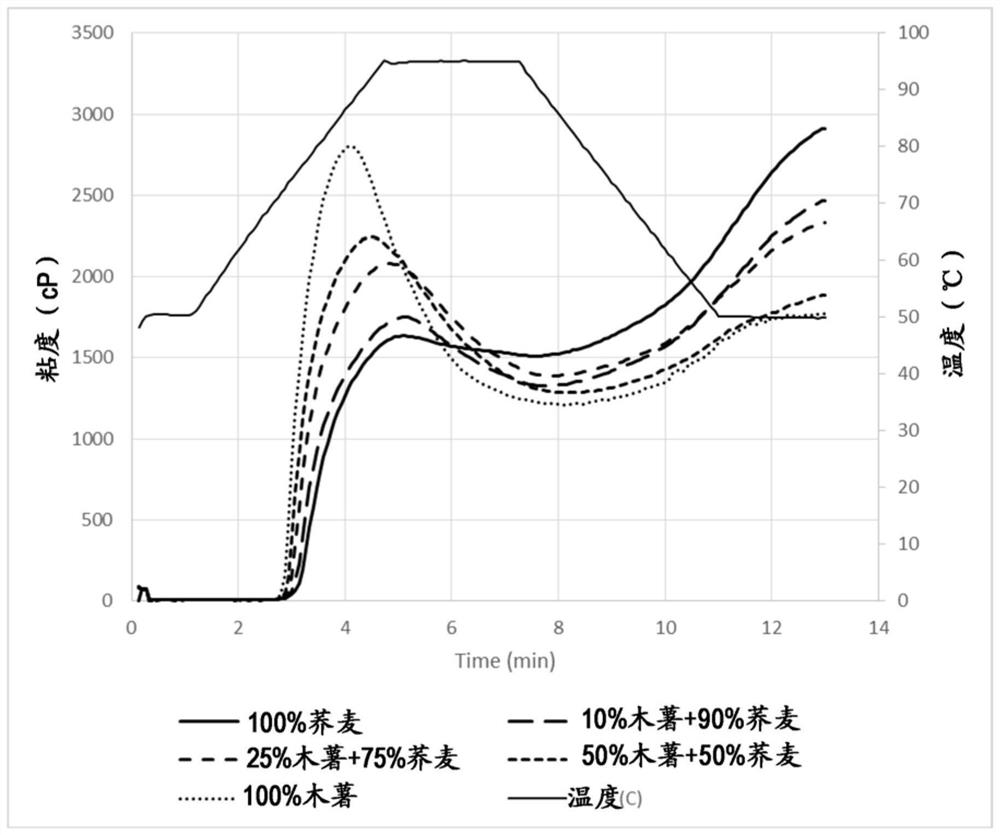

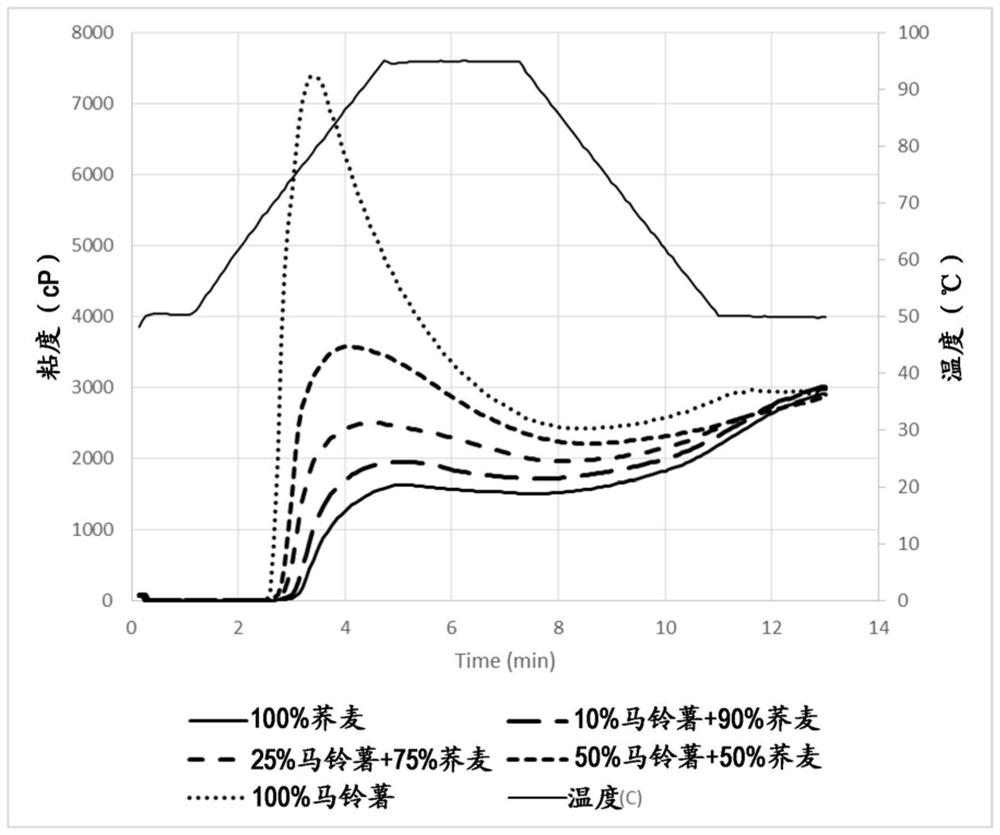

[0139] Example 1: Pasteability of buckwheat starch mixed with other starches

[0140] Table 1 below lists samples of each starch or starch mixture to be analyzed (2 g on a dry weight basis) mixed with water in aluminum cans to a final total weight of 25 g (8% starch suspension).

[0141]

[0142]

[0143] Table 1

[0144] Then, according to the heating curve shown in Table 2, each sample to be analyzed was heated using a rapid viscosity analyzer (RVA4500, Perten Instruments), and the viscosity and gelatinization temperature were measured simultaneously.

[0145] time temperature(℃) Shear speed (rpm) 00:00:00 50 960 00:00:10 50 160 00:01:00 50 160 00:04:45 95 160 00:07:15 95 160 00:11:00 50 160 00:13:00 50 160

[0146] Table 2

[0147] The gelatinization temperature is the temperature at which the viscosity begins to increase, as measured by a viscosity increase of more than 24 cP in 0.1 minutes.

[0148] Th...

Embodiment 2

[0157] Example 2: Properties of Buckwheat Starch and Potato Starch Mixture

[0158] The gelling properties, pasting properties and syneresis of the following samples were investigated:

[0159] - Natural Buckwheat Starch Batch 1 (called BWS1)

[0160] - Natural Buckwheat Starch Batch 2 (called BWS2)

[0161] - Native potato starch (called PS)

[0162] - Mixture: 10% Potato Starch (called PS) with 90% Buckwheat Starch Batch 1 (called BWS1)

[0163] -Mixture: 25% Potato Starch (called PS) with 75% Buckwheat Starch Batch 1 (called BWS1)

[0164] -Mixture: 10% Potato Starch (called PS) with 90% Buckwheat Starch Batch 2 (called BWS2)

[0165] -Mixture: 25% Potato Starch (called PS) with 75% Buckwheat Starch Batch 2 (called BWS2)

[0166] Starch gelatinization is the melting or destruction of the natural crystalline structure of starch such as by heat, pressure, shear and chemical action. After gelatinization in excess water, native starch granules lose their granular struct...

Embodiment 3

[0194] Example 3: Performance of yogurt prepared with buckwheat starch or a blend of buckwheat and potato starch compared with other clean label starches and chemically modified starches.

[0195] Seven yoghurt samples were prepared separately:

[0196] - buckwheat starch batch 1 (called BSW1),

[0197] - buckwheat starch batch 1 (called BSW2),

[0198] -A mixture of 90% buckwheat starch BSW1 and 10% potato starch (called BSW1-PS)

[0199] -A mixture of 90% buckwheat starch BSW2 and 10% potato starch (called BWS2-PS)

[0200] - Chemically modified waxy corn starch Clearam CJ 5025,

[0201] - functionalized clean label waxy cornstarch Novation 2300,

[0202] - Functionalized clean label waxy cornstarch Claria+

[0203] Buckwheat starch batch 1 was extracted from buckwheat groats using the first extraction method of buckwheat starch described in the instructions.

[0204] Buckwheat starch was extracted from buckwheat groats using the second extraction method of buckwheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com