Heating bunk bed for students

A heating and student technology, applied in the direction of bed, bed frame, application, etc., can solve the problem of unable to provide heating for students, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

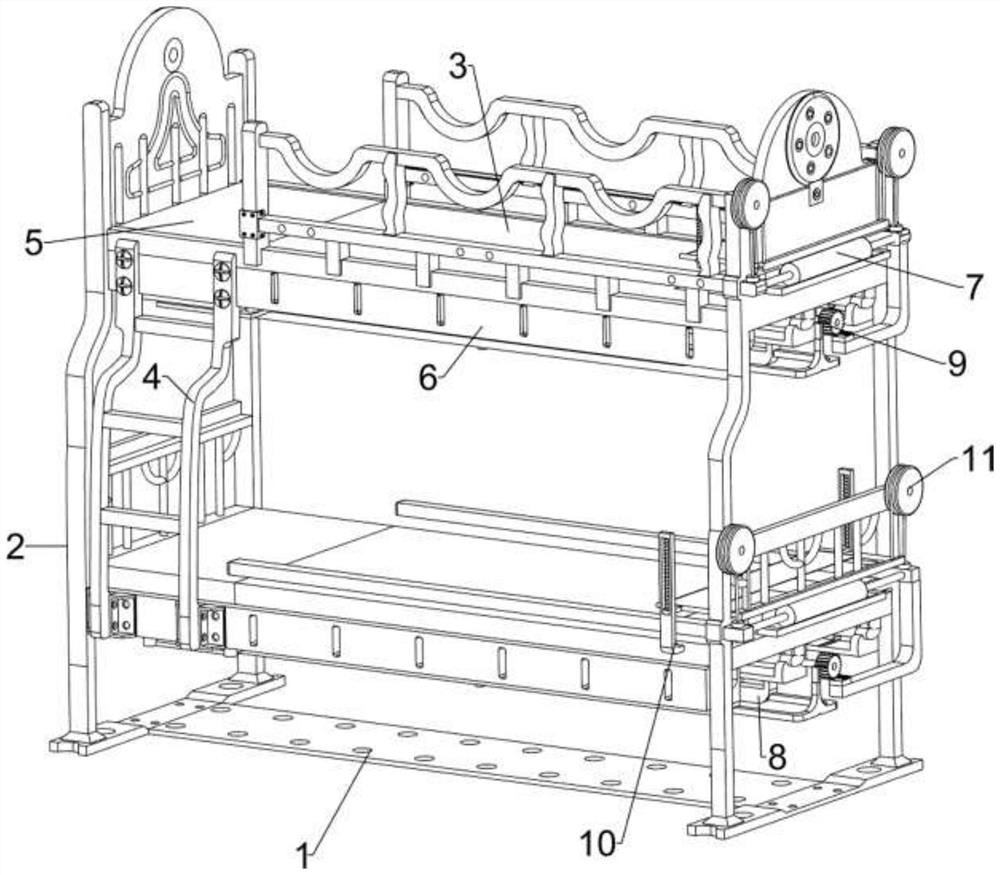

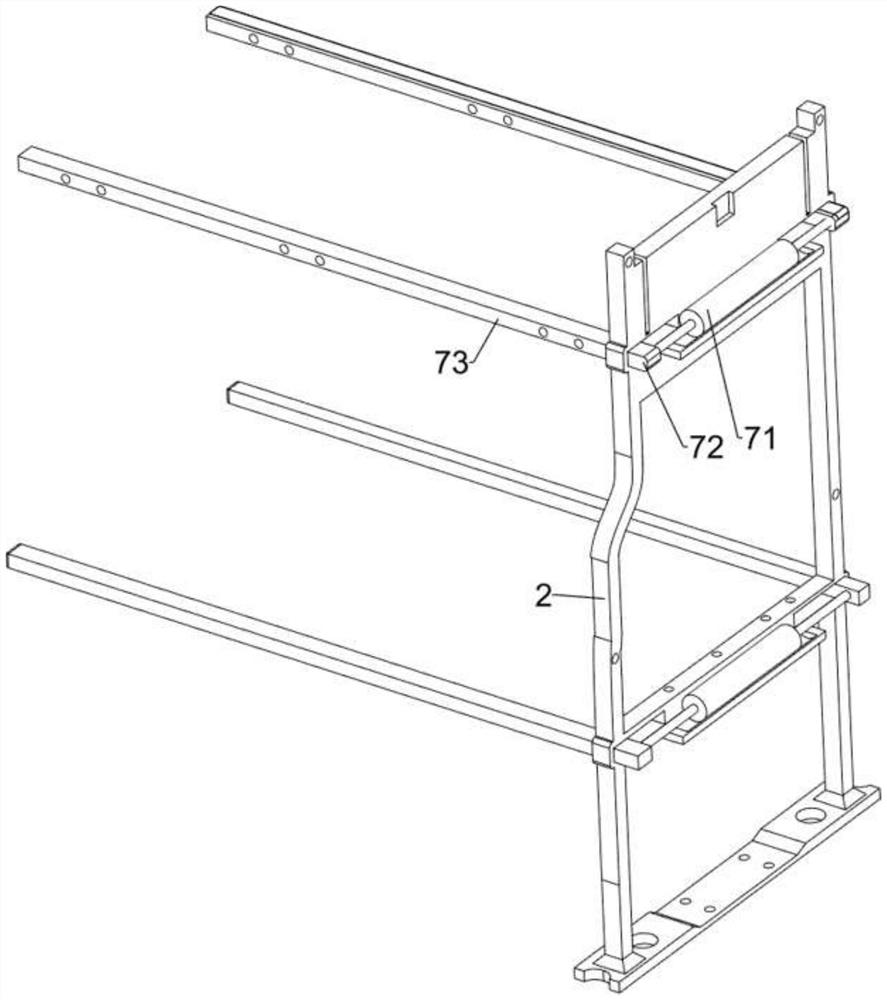

[0031] A heated bunk bed for students, such as Figure 1-3 As shown, it includes a base plate 1, a support plate 2, a bed plate 3, a ladder 4, a supporting plate 5, a heating assembly 6 and a drive assembly 7. The upper part of the base plate 1 is connected to the left and right sides of the support plate 2, and the support plates 2 on both sides are connected up and down. Both sides are connected with a bed board 3, and a ladder 4 is connected between the left front parts of the bed board 3 on both sides. A heating assembly 6 is connected, and a drive assembly 7 is connected to the upper and lower sides of the support plate 2 on the right side.

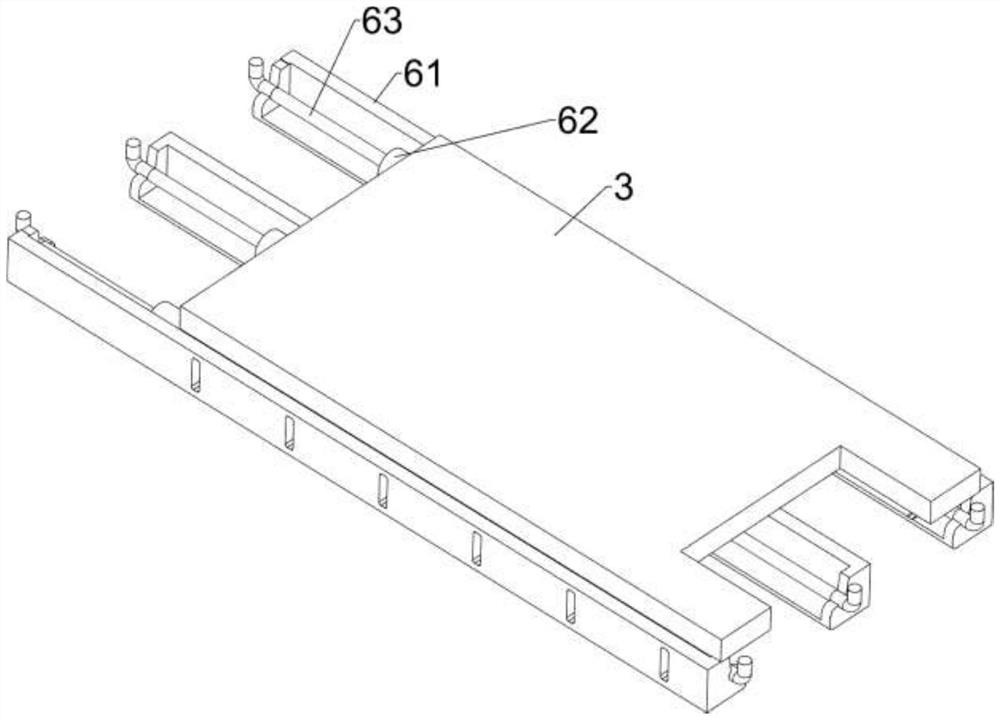

[0032] The heating assembly 6 includes a long frame 61, a heating pipe 62 and a heat conduction pipe 63. The lower parts of the bed boards 3 on both sides are connected with three long frames 61, and the middle and lower sides of the long frames 61 on both sides are provided with a heating pipe 62. Both left and right sides of the h...

Embodiment 2

[0036] On the basis of Example 1, such as figure 1 and Figure 4 As shown, it also includes a lifting assembly 8, and the lifting assembly 8 includes a connecting plate 81, a slide plate 82, a first spring 83, a guide rod 84 and a carriage 85, and there are connecting links between the lower parts of the three long frames 61 on the same side. Plate 81, the outer side of connecting plate 81 on both sides is all slidingly connected with slide plate 82, and the slide plate 82 on both sides cooperates with supporting plate 5 on the upper and lower both sides left parts, between the slide plate 82 on both sides and the connecting plate 81 on both sides Four first springs 83 are connected, and guide rods 84 are connected to the front and rear sides of the bottom of the bed board 3 on both sides, and a slide frame 85 is connected to the bottom right side of the slide plate 82 on both sides. The supporting plate 5 on the right part cooperates, and the sliding frame 85 on both sides i...

Embodiment 3

[0039] On the basis of Example 2, such as figure 1 and Figure 5 As shown, the first transmission assembly 9 is also included, and the first transmission assembly 9 includes an L-shaped bar 91, a first rack 92, a gear 93, a special-shaped bar 94 and a second rack 95, and the two sliders on the rear side 72 bottoms are all connected with L-shaped bar 91, and the front side of L-shaped bar 91 on both sides is all connected with first rack 92, and the right side of two long frames 61 in the middle of the upper and lower sides is all rotatably connected with gear 93, both sides The gear 93 meshes with the first rack 92 on both sides, the right side of the slide frame 85 on both sides is connected with a special-shaped rod 94, the top of the special-shaped rod 94 on both sides is connected with a second rack 95, and the second rack 95 on both sides is connected. The racks 95 are meshed with the gears 93 on both sides.

[0040] When the two sliders 72 on the rear side moved inward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com