Conveying mechanism and transfer printing system with conveying mechanism

A technology of transmission mechanism and transmission parts, applied in the field of transmission, which can solve the problems of lack of flipping function, low degree of automation in the transmission process, increased risk of workpiece damage and pollution, and achieve the effect of improving fluency and preventing jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

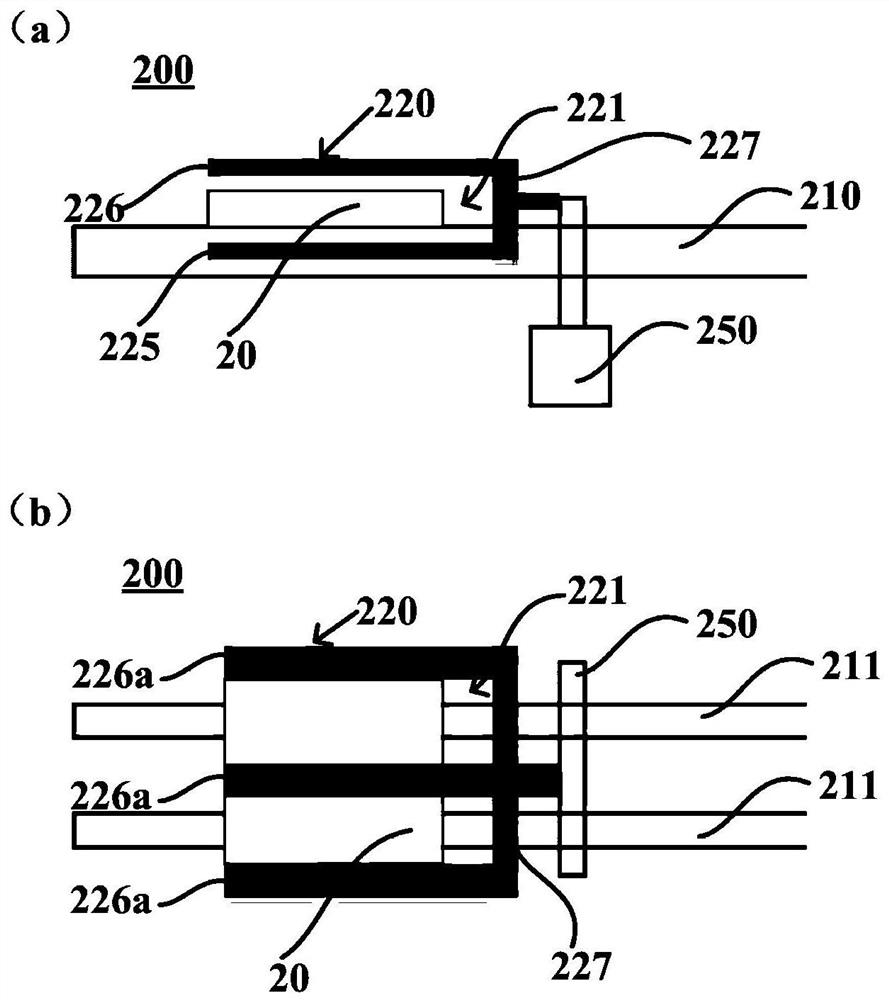

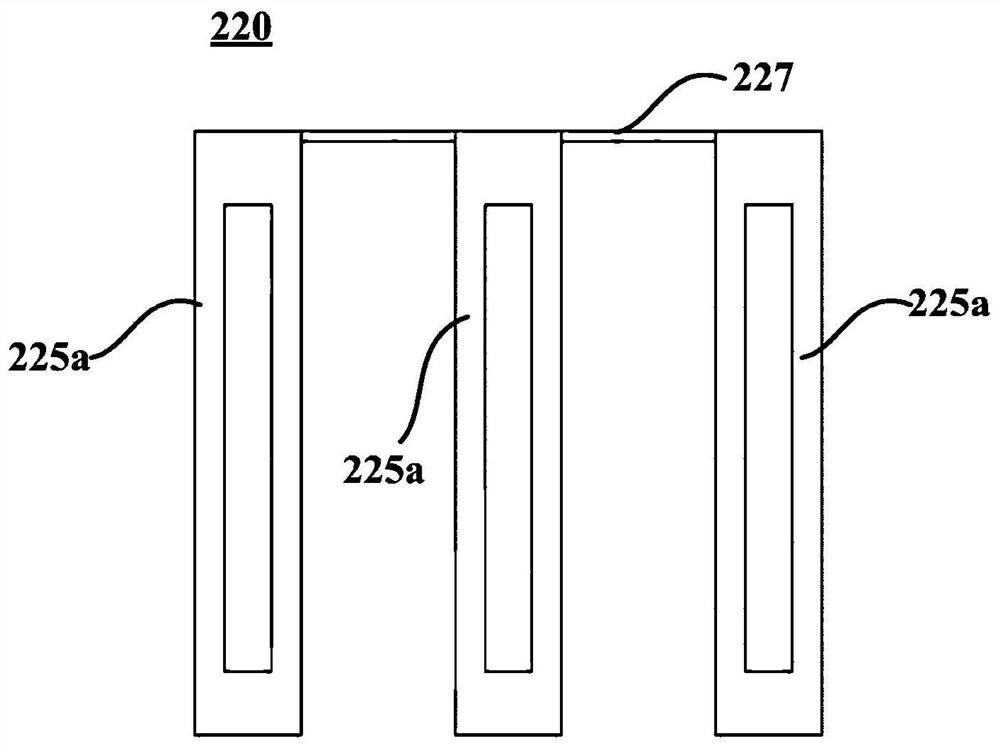

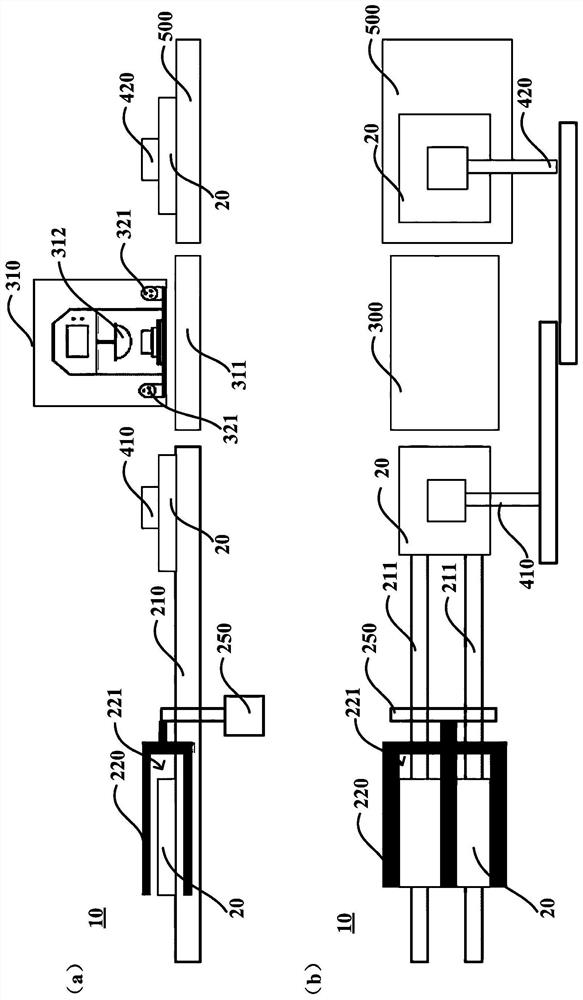

[0034] figure 1 is a schematic diagram of a delivery mechanism 200 according to an embodiment of the present invention, wherein figure 1 (a) is a front view, figure 1 (b) is a top view. In order to illustrate the position of the workpiece 20 on the conveying mechanism 200 , the figure also shows the workpiece 20 , but it should not be considered that the conveying mechanism 200 of this embodiment includes the workpiece 20 .

[0035] The conveying mechanism 200 may generally include a conveying member 210 and an overturning jig 220 , and may further include a driving mechanism 250 . The driving mechanism 250 includes a turning driving assembly (not shown) and a lifting driving assembly (not shown).

[0036] Wherein, the conveying member 210 is configured to drive the workpiece 20 to move along its conveying path. The conveying path of the conveying member 210 may refer to the moving path of the workpiece 20 on the conveying member 210 . The conveying member 210 may have a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com