A kind of preparation method of high-purity semi-insulating silicon carbide powder

A technology of silicon carbide powder and silicon carbide, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of composite catalysts, organic binders that are easy to introduce pollution, impurity gases and nitrogen impurities that are difficult to exclude, and increased powder preparation. Cost and other issues, to achieve the effect of controllable particle size, simple process, and improved heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of high-purity semi-insulating silicon carbide powder:

[0035] (1) Mix high-purity silicon powder and high-purity carbon powder with a molar ratio of 1:1.1 through a ball mill;

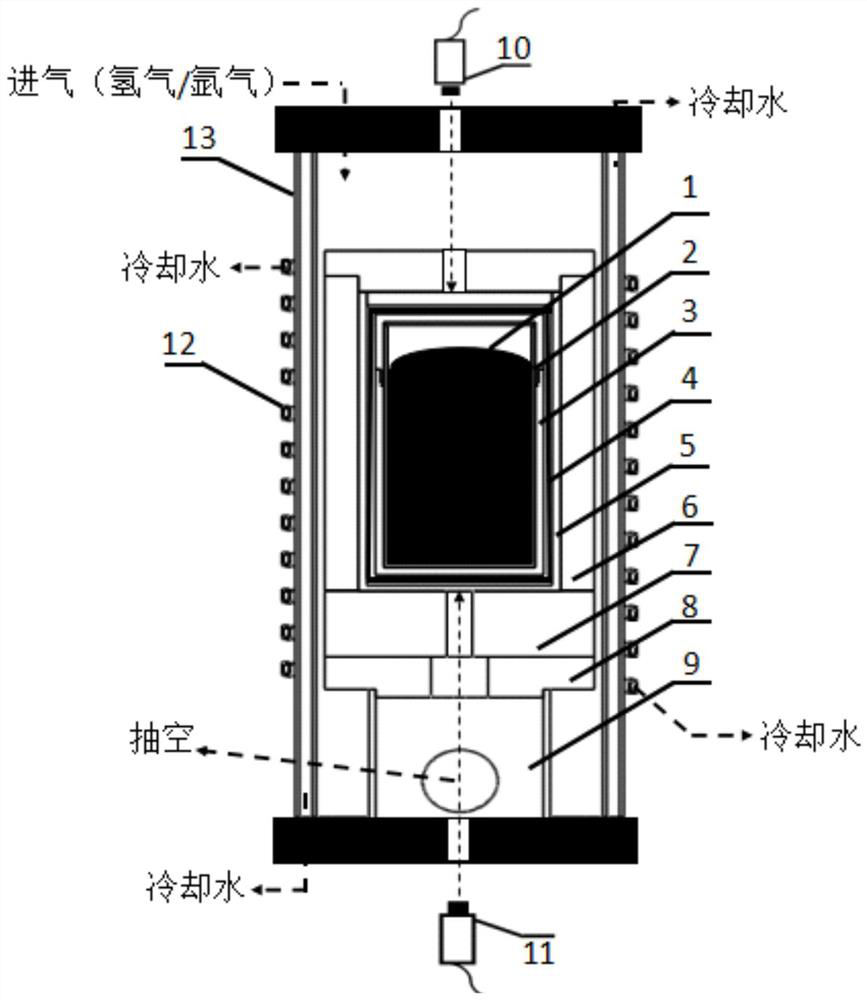

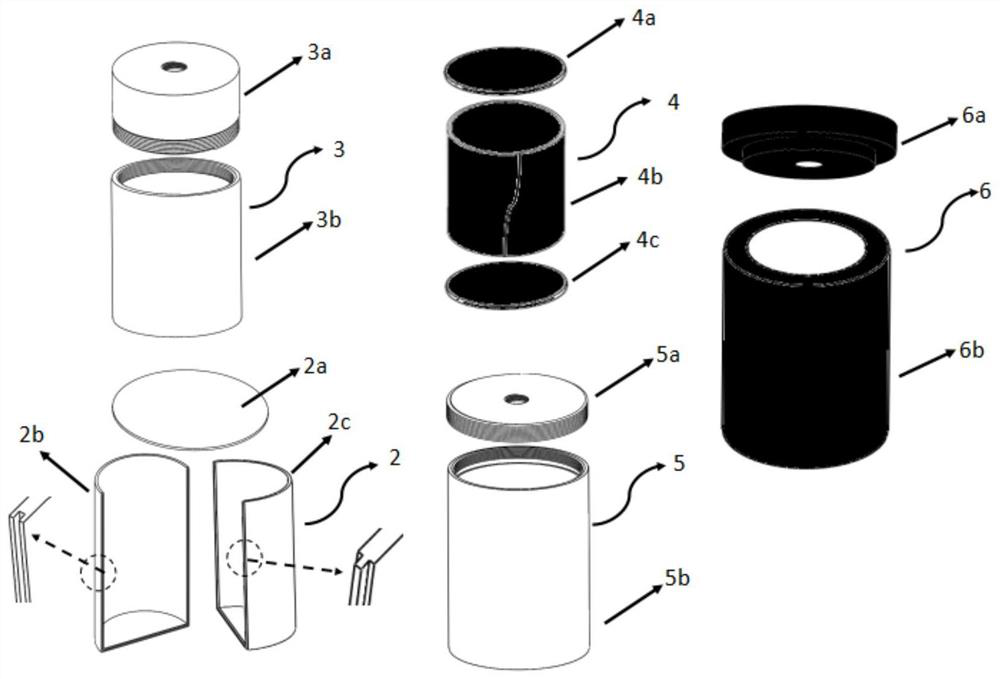

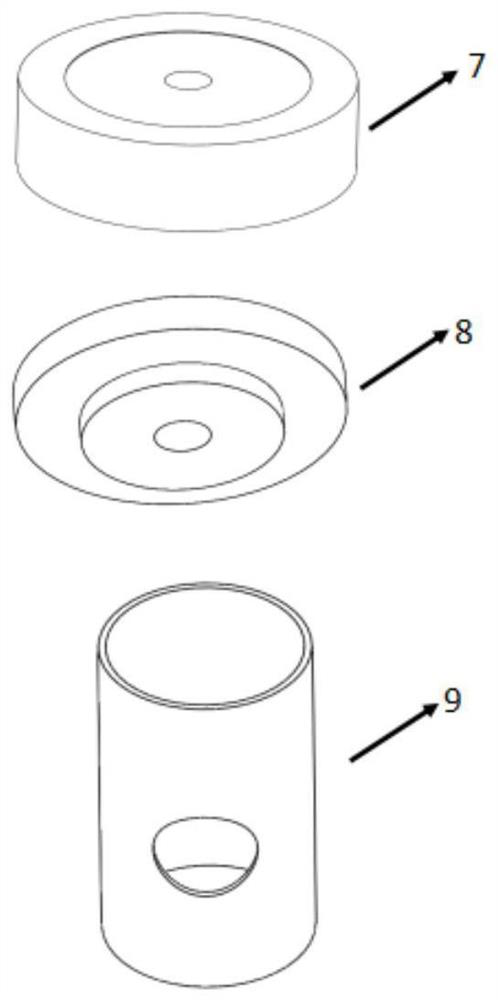

[0036] (2) loading the mixed raw materials into the silicon carbide crystal growth furnace;

[0037] (3) After pumping the furnace pressure to within 0.1mbar, start the molecular pump to pump finely to 5x10 -5 mbar, the duration is 5 hours, the temperature gradient in the furnace is controlled, the temperature gradient control can be divided into two stages, the first stage is the β phase of high-purity silicon carbide powder, the temperature is kept at 1600 degrees Celsius, and the time is kept for 15 hours to ensure that the silicon powder is completely volatilized. The pressure is 100mbar, the flow rate of argon gas is 150 sccm, and the flow rate of hydrogen gas is 15 sccm;

[0038] (4) In the second stage, the semi-insulating high-purity silicon carbide powder synthe...

Embodiment 2

[0044] A preparation method of high-purity semi-insulating silicon carbide powder:

[0045] (1) Mix high-purity silicon powder and high-purity carbon powder with a molar ratio of 1:1.1 through a ball mill;

[0046] (2) loading the mixed raw materials into the silicon carbide crystal growth furnace;

[0047] (3) After pumping the furnace pressure to within 0.1mbar, start the molecular pump to pump finely to 5x10 -5 mbar, the duration is 5h, the temperature gradient in the furnace is controlled, the temperature gradient control can be divided into two stages, the first stage is the β phase of high-purity silicon carbide powder, the temperature is kept at 1400-1600 degrees Celsius, and the time is 10-15h to ensure that the silicon powder is completely For volatilization, the chamber pressure is 100mbar, the flow rate of argon gas is 150 sccm, and the flow rate of hydrogen gas is 15 sccm;

[0048] (4) In the second stage, the semi-insulating high-purity silicon carbide powder sy...

Embodiment 3

[0054] A preparation method of high-purity semi-insulating silicon carbide powder:

[0055] (1) Mix high-purity silicon powder and high-purity carbon powder with a molar ratio of 1:1.1 through a ball mill;

[0056] (2) loading the mixed raw materials into the silicon carbide crystal growth furnace;

[0057] (3) After pumping the furnace pressure to within 0.1mbar, start the molecular pump to pump finely to 5x10 -5 mbar, the duration is 5 hours, the temperature gradient in the furnace is controlled, the temperature gradient control can be divided into two stages, the first stage is the β phase of high-purity silicon carbide powder, the temperature is kept at 1400-1600 degrees Celsius, and the time is 8-15 hours to ensure that the silicon powder is completely For volatilization, the chamber pressure is 100mbar, the flow rate of argon gas is 150 sccm, and the flow rate of hydrogen gas is 15 sccm;

[0058] (4) In the second stage, the semi-insulating high-purity silicon carbide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com