Cr13 type stainless steel wire rod and annealing method thereof

A stainless steel plate and annealing technology, which is applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems of long annealing time, difficulty in pickling, high energy consumption of annealing, etc., and achieve easy pickling, increase production efficiency, and reduce oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

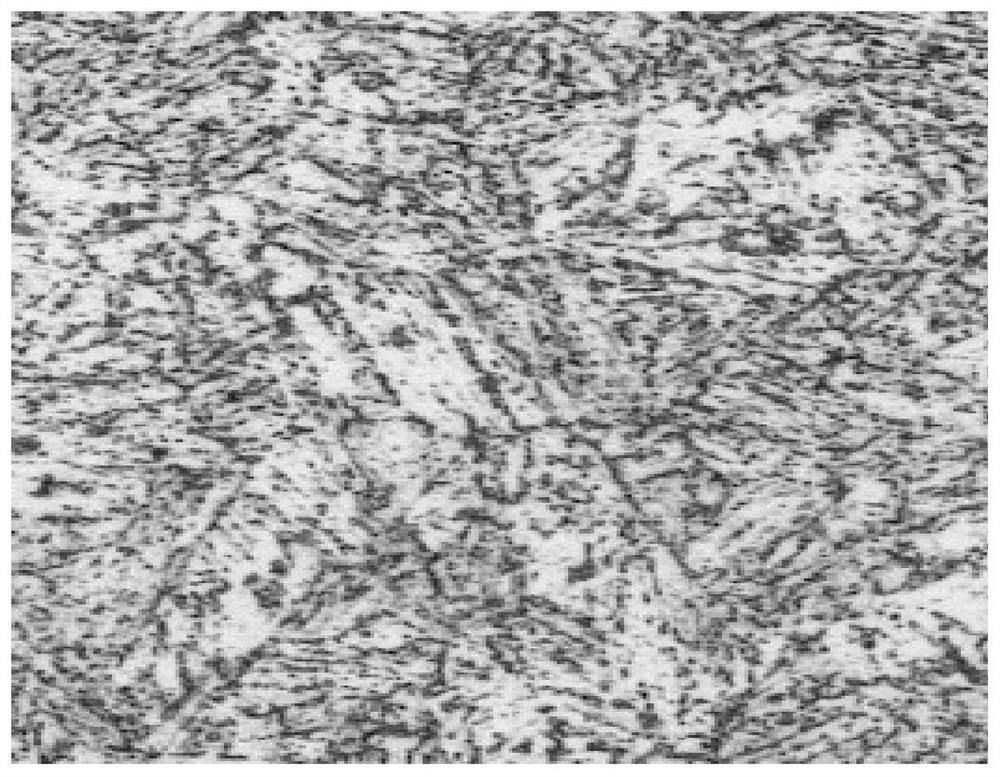

Image

Examples

Embodiment 1

[0048] The Cr13 type stainless steel wire rod steel grade of this embodiment is 12Cr13, and the diameter of the wire rod is 5.50 millimeters.

[0049] After the wire rod is rolled, the high-temperature state enters the roller bottom tunnel furnace next to the rolling mill to keep warm for a period of time and then cools to complete the annealing. Among them, the final rolling temperature of the wire rod is 1000°C, and the temperature when the wire rod enters the tunnel furnace is 850°C. The holding temperature of the tunnel furnace is 760°C, the holding time in the tunnel furnace is 60 minutes, and the wire rod is air-cooled after it comes out of the furnace.

[0050] After testing, the hardness HB of the wire rod is 184, which meets the requirement of hardness HB≤187 in the GB / T 1220-2016 standard.

[0051] The surface oxidation degree of the wire rod is low, the pickling time is 20 minutes, and the pickling metal loss is 1.8%.

Embodiment 2

[0053] The Cr13 type stainless steel wire rod steel grade of the present embodiment is 20Cr13, and the diameter of the wire rod is 12 millimeters.

[0054] After the wire rod is rolled, the high-temperature state enters the roller bottom tunnel furnace next to the rolling mill to keep warm for a period of time and then cools to complete the annealing. Among them, the final rolling temperature of the wire rod is 850°C, and the temperature when the wire rod enters the tunnel furnace is 780°C. The holding temperature of the tunnel furnace is 760°C, the holding time in the tunnel furnace is 60 minutes, and the wire rod is air-cooled after it comes out of the furnace.

[0055] After testing, the hardness HB of the wire rod is 190, which meets the requirement of hardness HB≤223 in the GB / T 1220-2016 standard.

[0056] The surface oxidation degree of the wire rod is low, the pickling time is 20 minutes, and the pickling metal loss is 1.9%.

Embodiment 3

[0058] The Cr13 type stainless steel wire rod steel grade of the present embodiment is 30Cr13, and the diameter of the wire rod is 6.50 millimeters.

[0059] After the wire rod is rolled, the high-temperature state enters the roller bottom tunnel furnace next to the rolling mill to keep warm for a period of time and then cools to complete the annealing. Among them, the final rolling temperature of the wire rod is 900°C, and the temperature when the wire rod enters the tunnel furnace is 800°C. The holding temperature of the tunnel furnace is 760°C, the holding time in the tunnel furnace is 60 minutes, and the wire rod is air-cooled after it comes out of the furnace.

[0060] After testing, the hardness HB of the wire rod is 218, which meets the requirement of hardness HB≤235 in the GB / T 1220-2016 standard.

[0061] The surface oxidation degree of the wire rod is low, the pickling time is 18 minutes, and the pickling metal loss is 1.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com